A storage degradation analysis method for mechanical properties of relays

An analysis method and relay technology, applied in the direction of instruments, design optimization/simulation, electrical digital data processing, etc., can solve the problems that the change of the mechanical performance of the relay cannot be given, and achieve the effect of saving test cost and reducing test difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

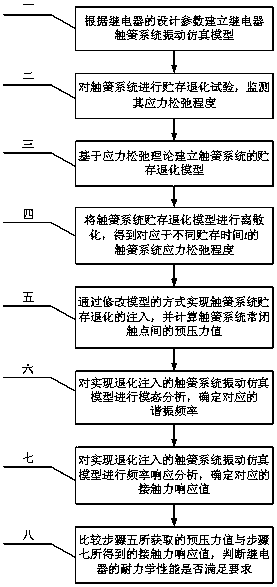

[0021] Specific implementation mode one: the following combination figure 1 Describe this embodiment, this embodiment discloses a kind of method for determining the characteristic parameter of storage degradation of the contact spring system of an electromagnetic relay, which includes the following steps:

[0022] Step 1: Establish a vibration simulation model of the relay contact spring system according to the design parameters of the relay;

[0023] Step 2: Conduct a storage degradation test on the contact spring system, and monitor the degree of stress relaxation at different moments during the test;

[0024] Step 3: Based on the test data obtained in Step 2, a storage degradation model of the contact spring system is established based on the stress relaxation theory;

[0025] Step 4: discretize the storage degradation model of the contact spring system obtained in step 3, and obtain the stress relaxation degree D(t) of the contact spring system corresponding to different ...

specific Embodiment approach 2

[0030] Specific implementation mode two: the following combination figure 1 This embodiment is described. This embodiment is a further description of the specific embodiment one. The relay design parameters in step one include the dimensions, tolerances, and material properties of the relay itself and its components;

[0031] The establishment of the vibration simulation model of the relay contact spring system according to the design parameters of the relay is realized by ANSYSWORKBENCH (a software name);

[0032] The stress relaxation degree of the contact spring system described in step 2 is the deformation amount of the elastic element;

[0033] The stress relaxation theory described in step three uses the Larson-Miller formula:

[0034]

[0035] In the formula, θ is the Larson-Miller parameter; T is the temperature in degrees Celsius; t is the storage time; C Usually taken as 20;

[0036] The discretization of the storage degradation model of the contact spring ...

specific Embodiment approach 3

[0041] Specific implementation mode three: the following combination figure 1 , figure 2 , image 3 This implementation mode is described, and this implementation mode is a further description of the specific implementation mode 1 and the second implementation mode. The application object of this embodiment is a certain type of electromagnetic relay.

[0042]Step 1: Establish a vibration simulation model of a certain type of relay contact spring system in ANSYS WORKBENCH according to the design parameters of the relay, such as figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com