Wall climbing machine used for wall climbing work

A wall climbing machine and wall machine technology, which is applied in the directions of motor vehicles, transportation and packaging, can solve problems such as increasing operating costs, and achieve the effect of reducing operating costs and avoiding personal safety risks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

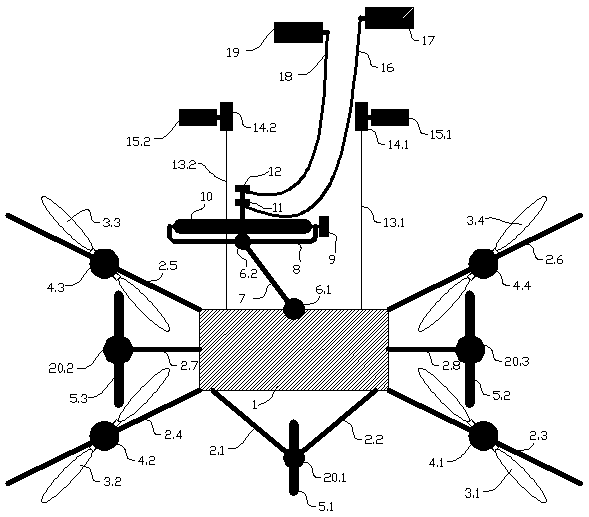

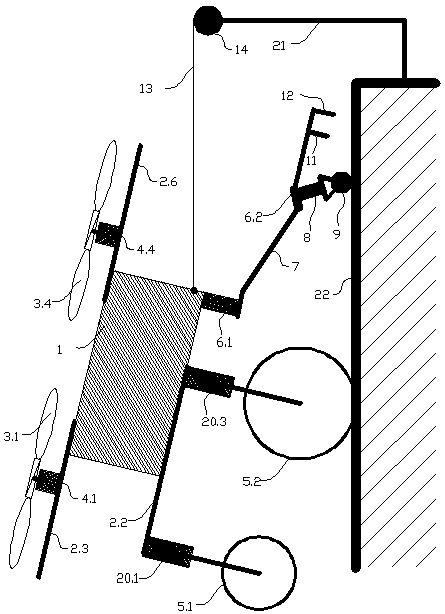

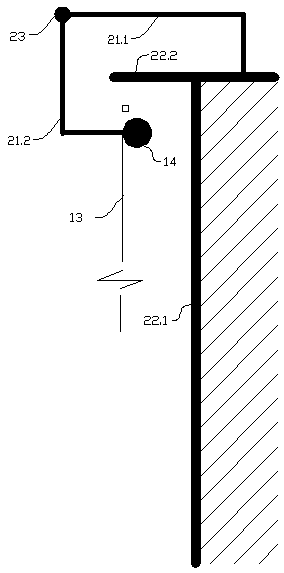

[0021] Such as figure 1 As shown, the wall climbing machine (1) has four propellers (3), and the rotation plane of the propellers (3) is located in the vertical plane, so the propellers (3) generate horizontal thrust when rotating. The motor drive device of the climbing machine (1) comprises a traction rope (13), a wheel (14) and a drive motor (15). Driven by the drive motor (15), the wheel (14) rotates, driving the climbing machine body (1) to move up and down. The high-pressure water provided by the high-pressure water pump (17) is provided to the high-pressure water fan-shaped nozzle (11) through the water delivery pipe (16). The high-pressure gas provided by the air compressor (19) is provided to the high-pressure fan-shaped spray nozzle (12) through the gas delivery pipe (18). The rotary wiper (10), the high-pressure water fan-shaped nozzle (11) and the high-pressure fan-shaped nozzle (12) together form a wall (22) cleaning system. Among them, the rotary wiper (10) ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com