Pull head mounting machine

A head machine and slider technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of high labor cost and low labor efficiency, and achieve the effects of simple structure, stable operation and stable working state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing with specific embodiment:

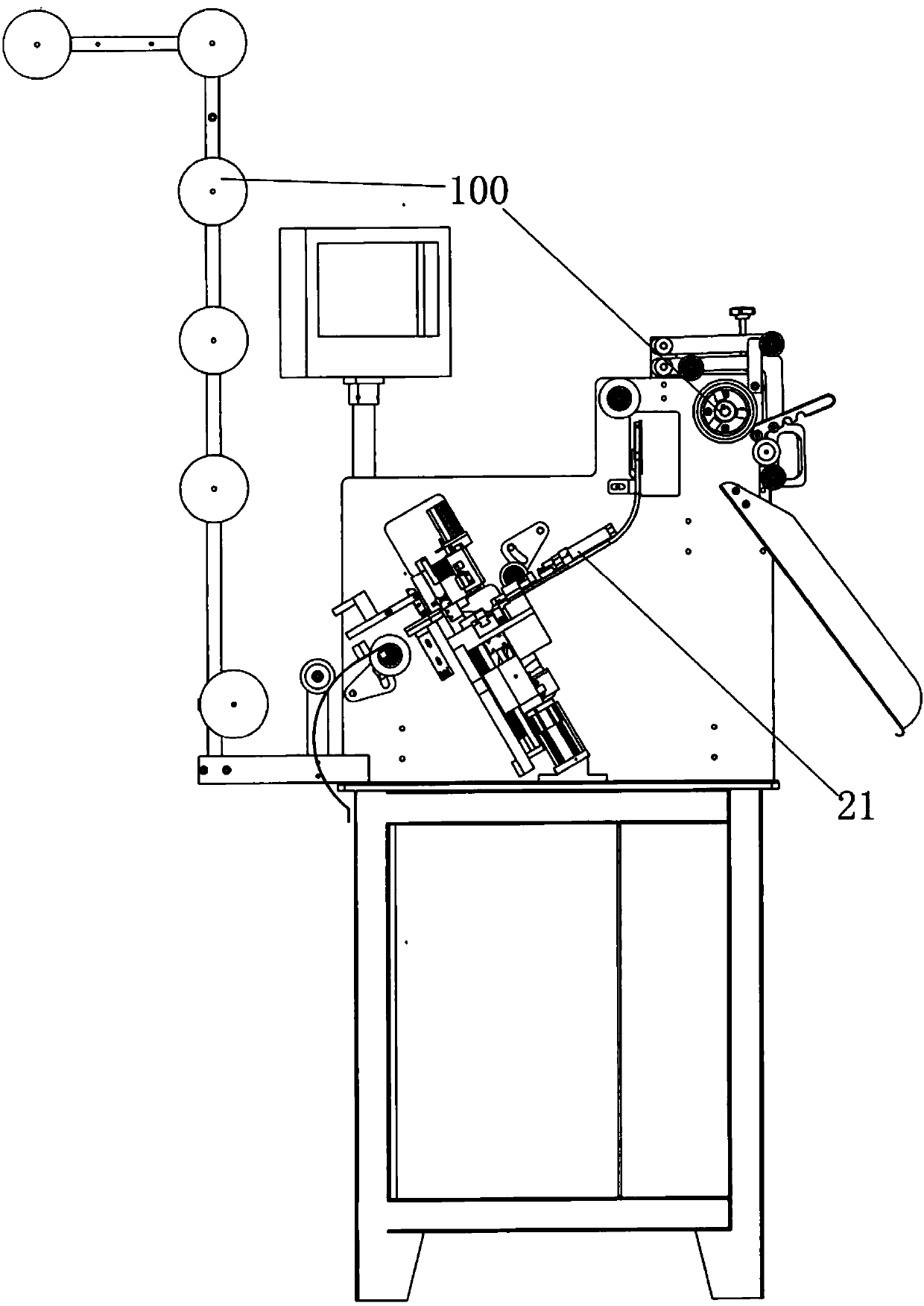

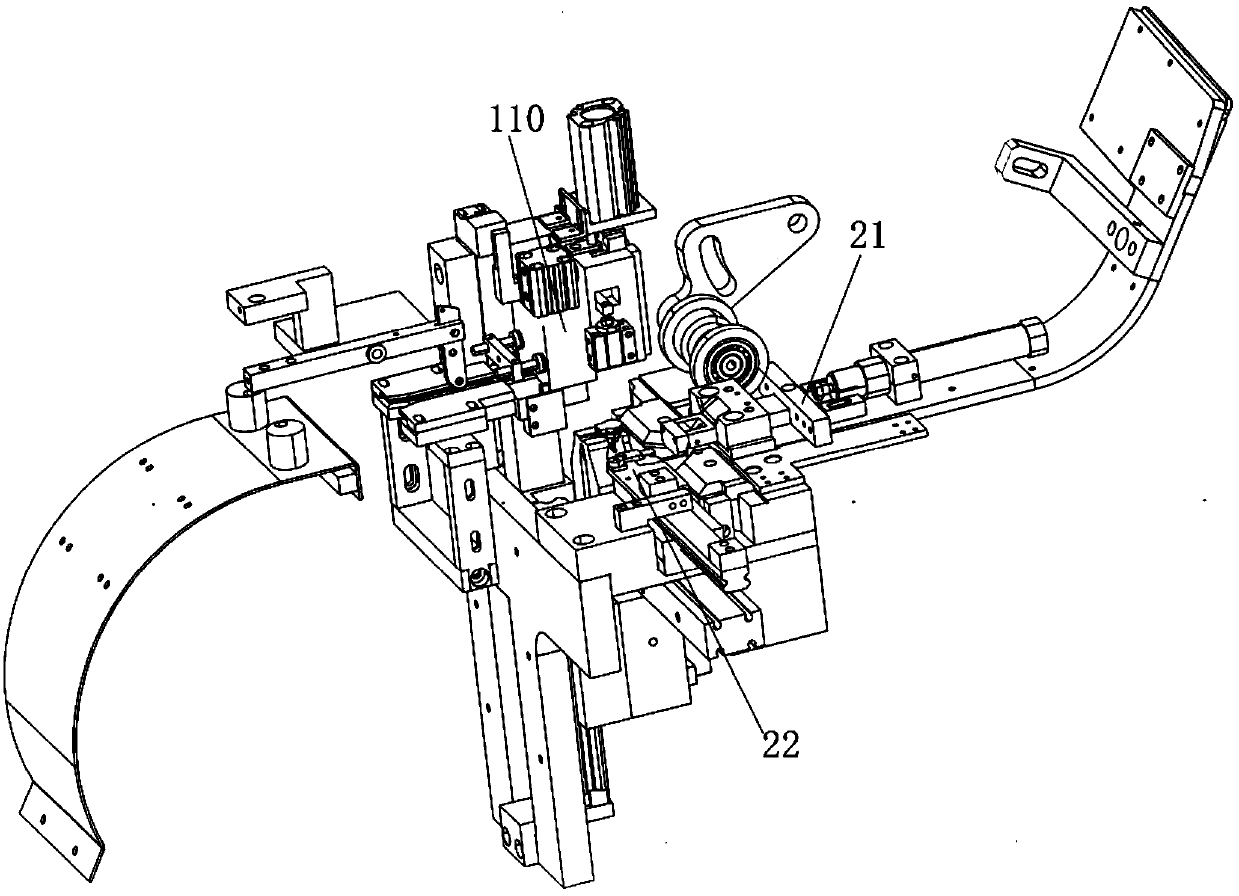

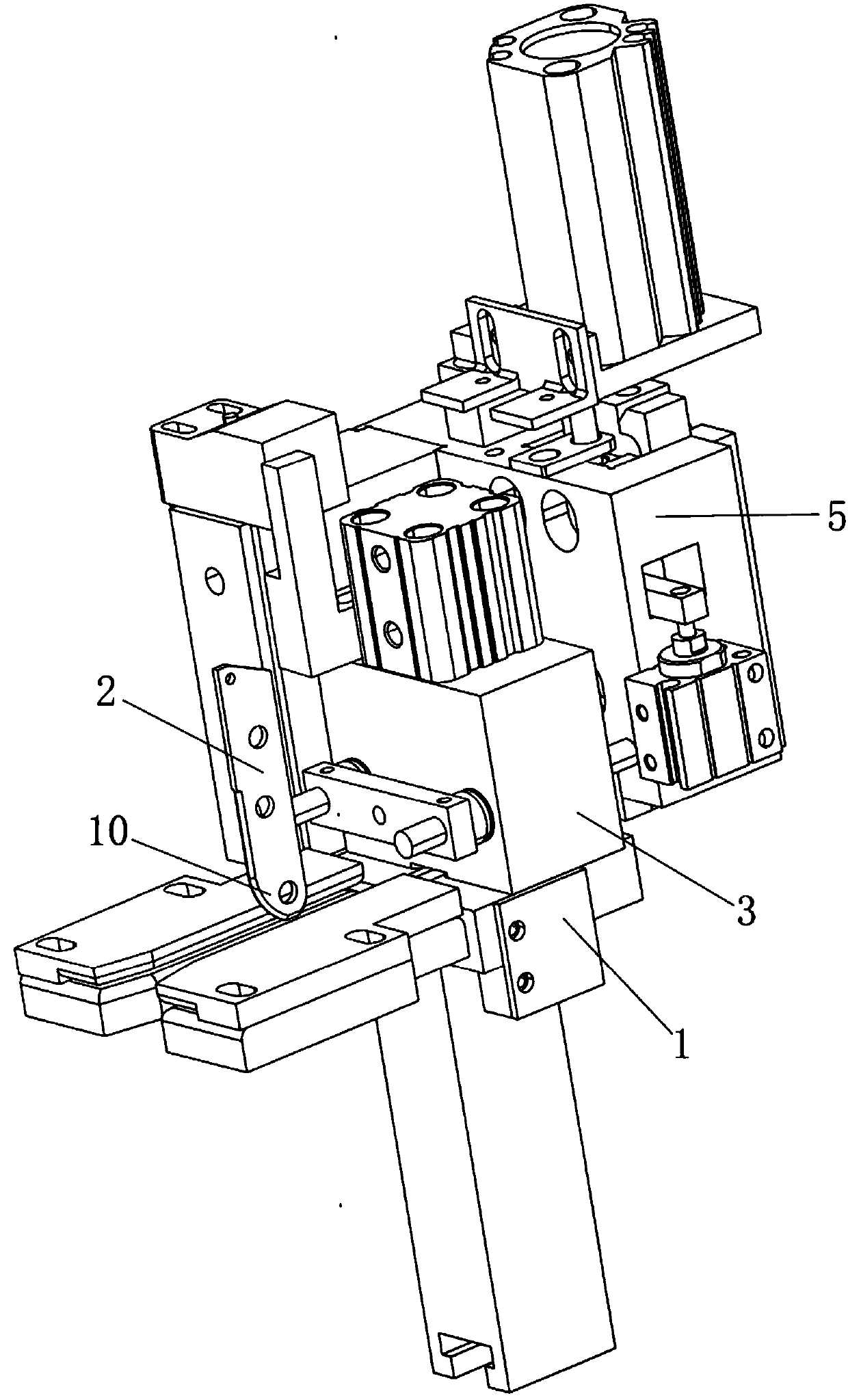

[0038]A slider-up machine, comprising a zipper conveying device 100, a slider conveying device, a chain splitting device 110 and a chain combining device, the chain splitting device including a chain splitting platform 1 and a first driving device that drives the chain splitting unit 1 to move up and down , the front of the chain dividing platform 1 is provided with an induction part 2, and the upper surface of the dividing chain platform 1 is provided with a slider 3 that can move along the direction of zipper conveying, and the slider 3 is provided with a first minute hand 4 and for the first minute hand to move up and down. In the telescopic space of the movement, the slider 3 is fixed with a second driving device that drives the first minute hand 4 to move up and down, and a fixing frame 5 is arranged behind the chain dividing table 1, and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com