Automatic conveying and rapping system for medical waste treatment

A technology for medical waste and automatic transportation, which is used in liquid processing, transportation and packaging, emptying containers, etc., can solve the problems of incomplete dumping of large boxes of materials, manual compaction of large boxes of materials, and high labor intensity of operators. Realize the effect of on-site unmanned operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

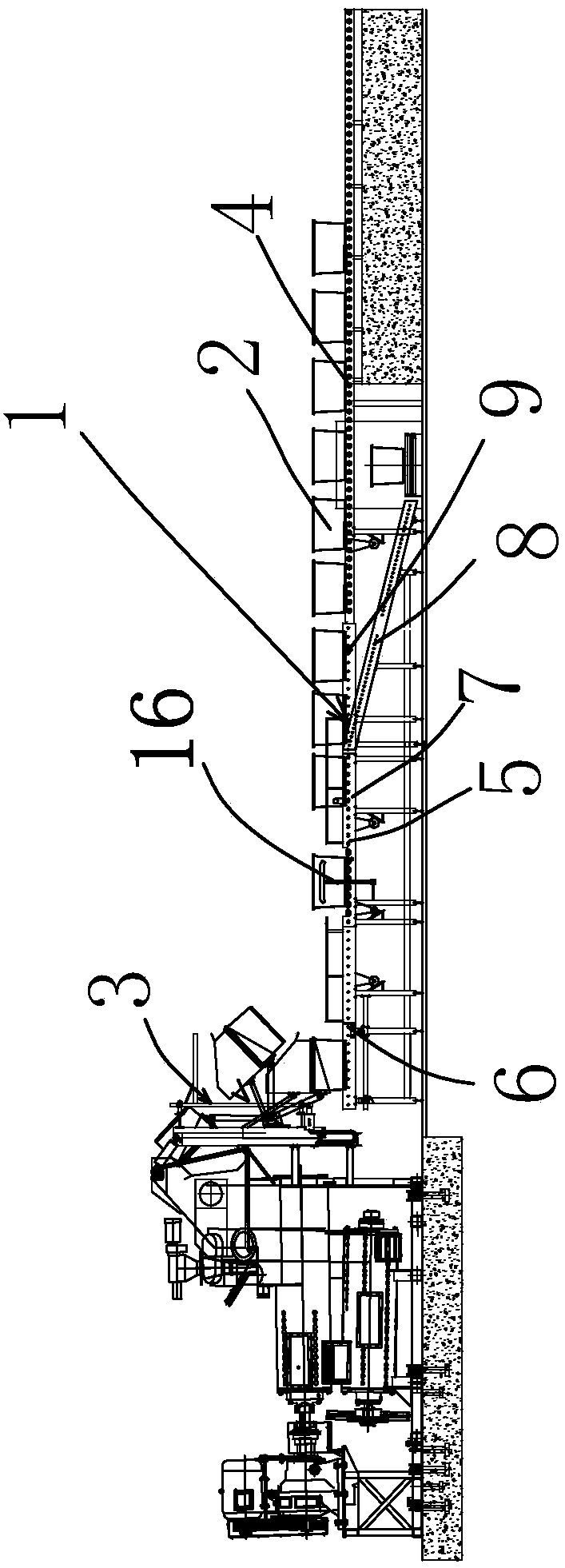

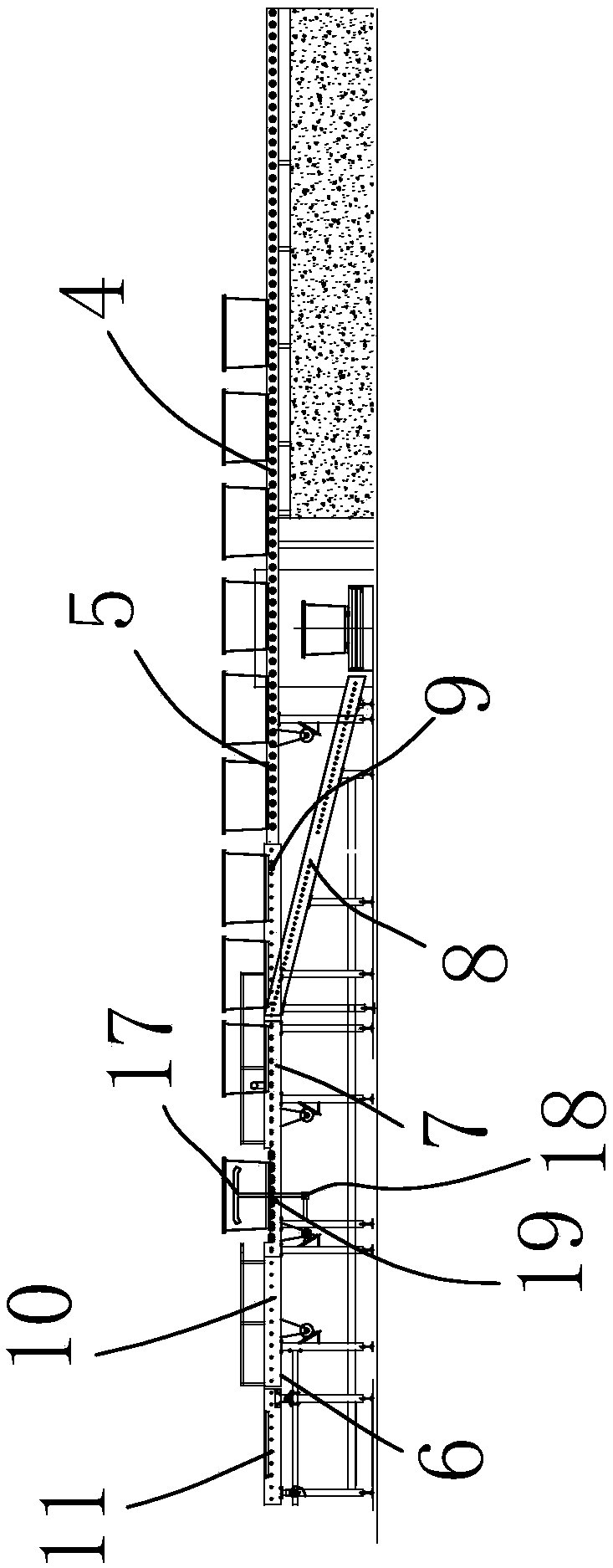

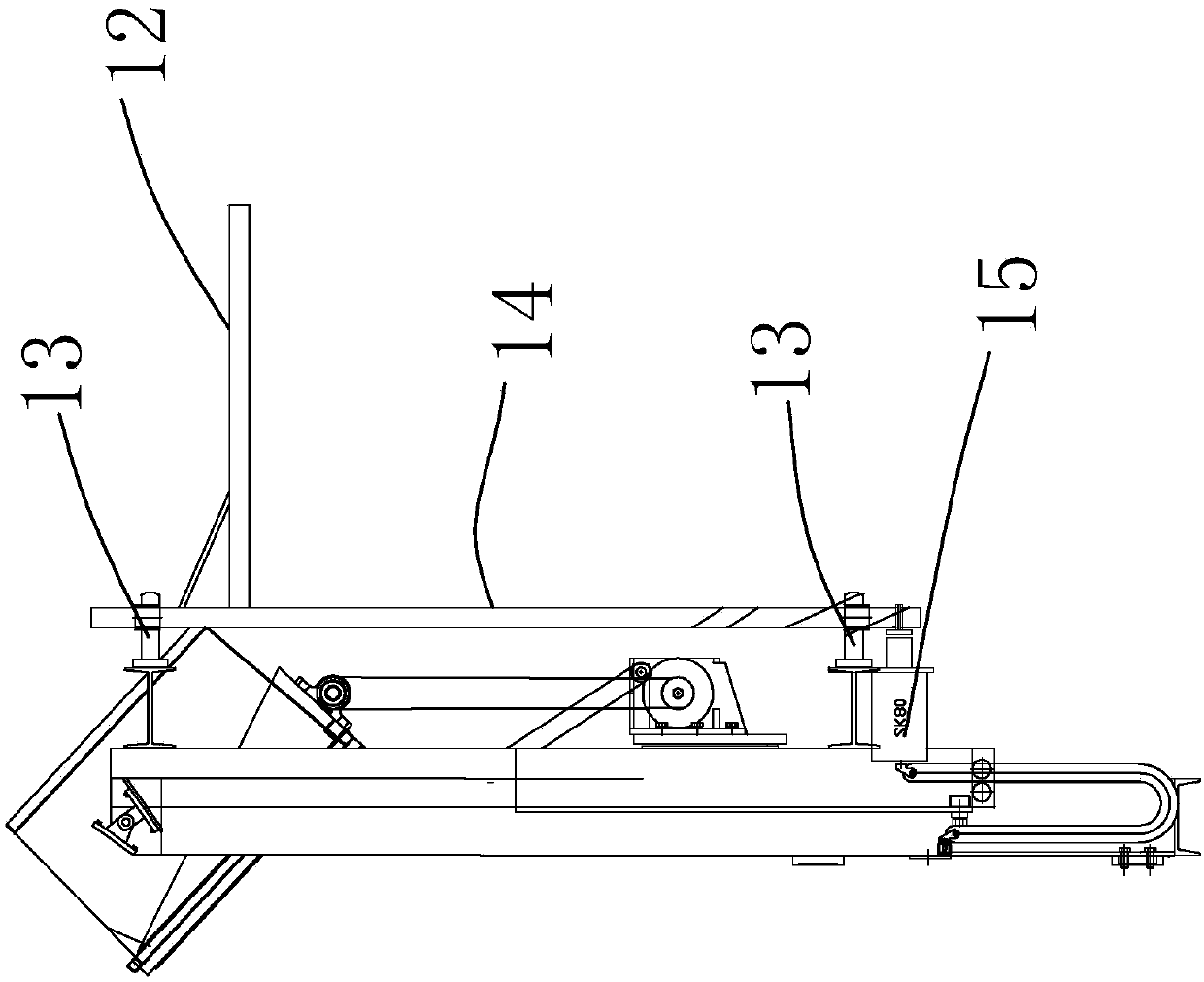

[0018] In the figure, the conveying roller part 1; the box body 2; the rapping part 3; the primary conveying roller 4; the power conveying roller 5; the secondary conveying roller 6; the empty box conveying roller 7; the slope roller 8; One-shot photoelectric switch 9; one-stage conveying roller table 10; second-stage conveying roller table 11; hammering rod 12; fixed sleeve rod 13; rotating rod 14; pneumatic drive assembly 15; Rod pneumatic part 18; second through-beam photoelectric switch 19.

[0019] Such as figure 1 As shown, the automatic conveying and rapping system for medical waste treatment mainly realizes the automatic loading of materials and the recycling of empty boxes 2 during medical waste treatment. body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com