Reaction kettle for producing liquid fertilizer

A liquid fertilizer and reactor technology, applied in chemical/physical/physicochemical fixed reactors, mixers with rotating stirring devices, mixers, etc., can solve the problems of clogged nozzles, drip irrigation heads, single structure, precipitation, etc., Achieve full and uniform mixing, ensure quality effect, and evenly stir the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing and example.

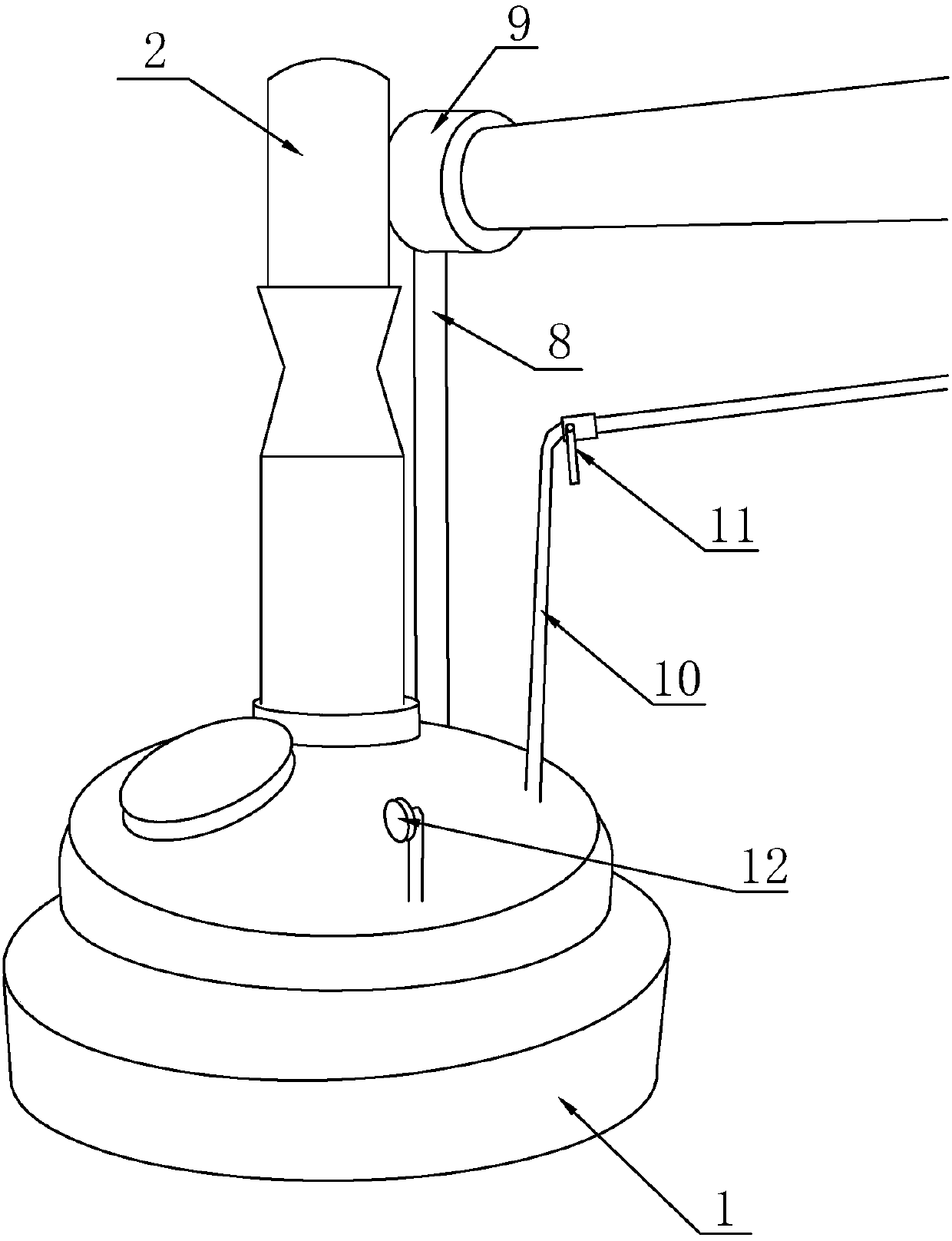

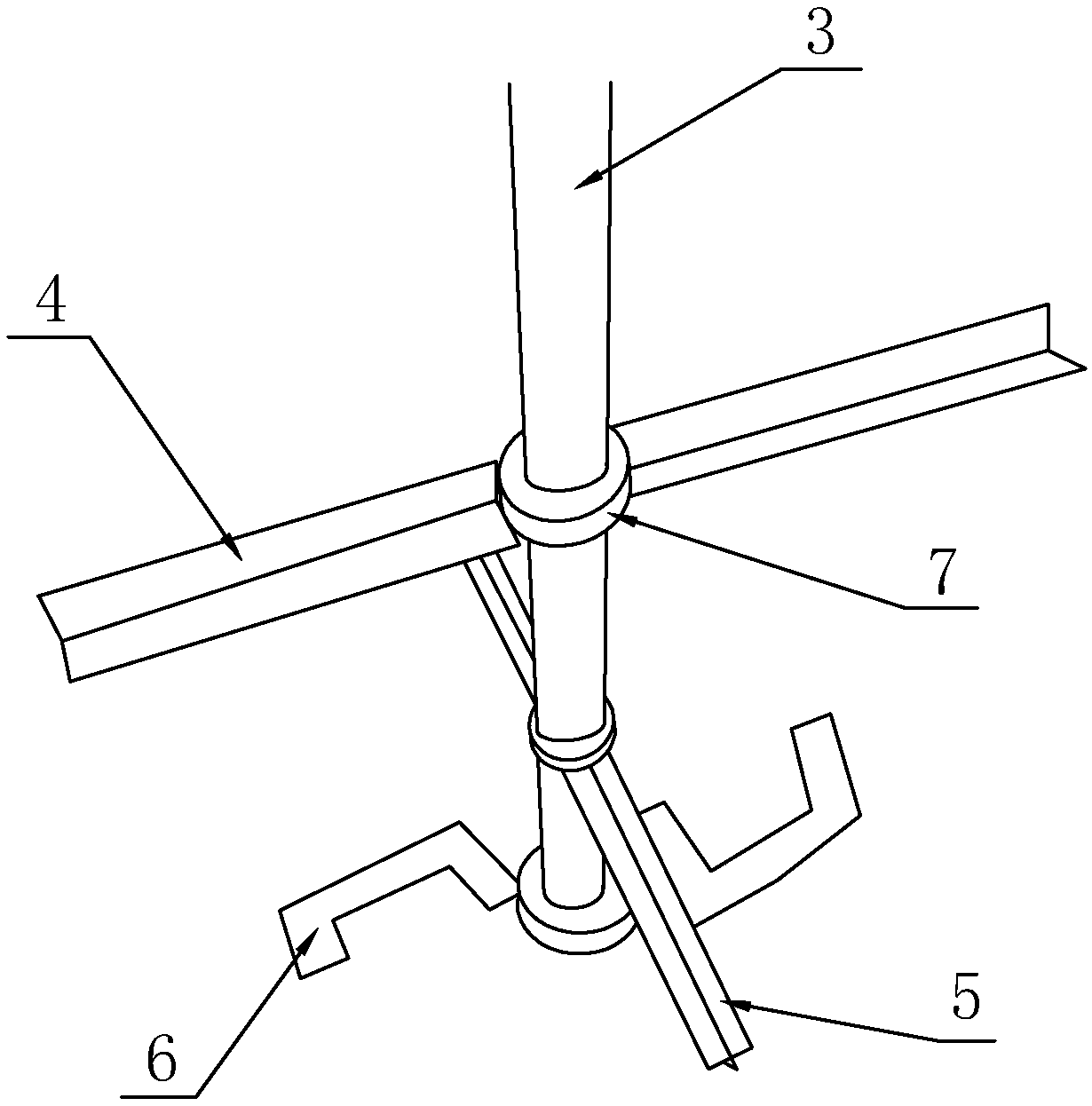

[0021] Such as Figure 1-3 As shown, the present invention provides a reaction kettle for producing liquid fertilizer, comprising a kettle body 1, a driving device 2 is connected above the kettle body 1, a transmission shaft 3 is connected below the driving device 2, and the transmission shaft 3 is arranged on the kettle body 1 Inside, the transmission shaft 3 is provided with a first stirring bar 4, a second stirring bar 5 and a third stirring bar 6 in sequence from top to bottom, the first stirring bar 4 is bent at a right angle, and the second stirring bar 5 is in the shape of a cross star. The second stirring bar 5 and the first stirring bar 4 are perpendicular to each other, and the third stirring bar 6 is bowed. The first stirring bar 4, the second stirring bar 5 and the third stirring bar 6 arranged in sequence from top to bottom of the transmission shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com