A contact arc extinguishing system, a low-voltage circuit breaker and an arc extinguishing system

A contact system and arc extinguishing technology, applied in circuit breaker parts and other directions, can solve the problems of increasing product manufacturing costs, difficult to control contact synchronization, and difficult to control performance parameters, so as to improve the breaking speed and facilitate arc extinguishing. , the effect of reducing the arc cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the use of adjective or adverbial modifiers "horizontal" and "vertical", "upper" and "lower" etc. is only for relative reference between groups of terms, and does not describe any reference to the modified term. specific orientation constraints.

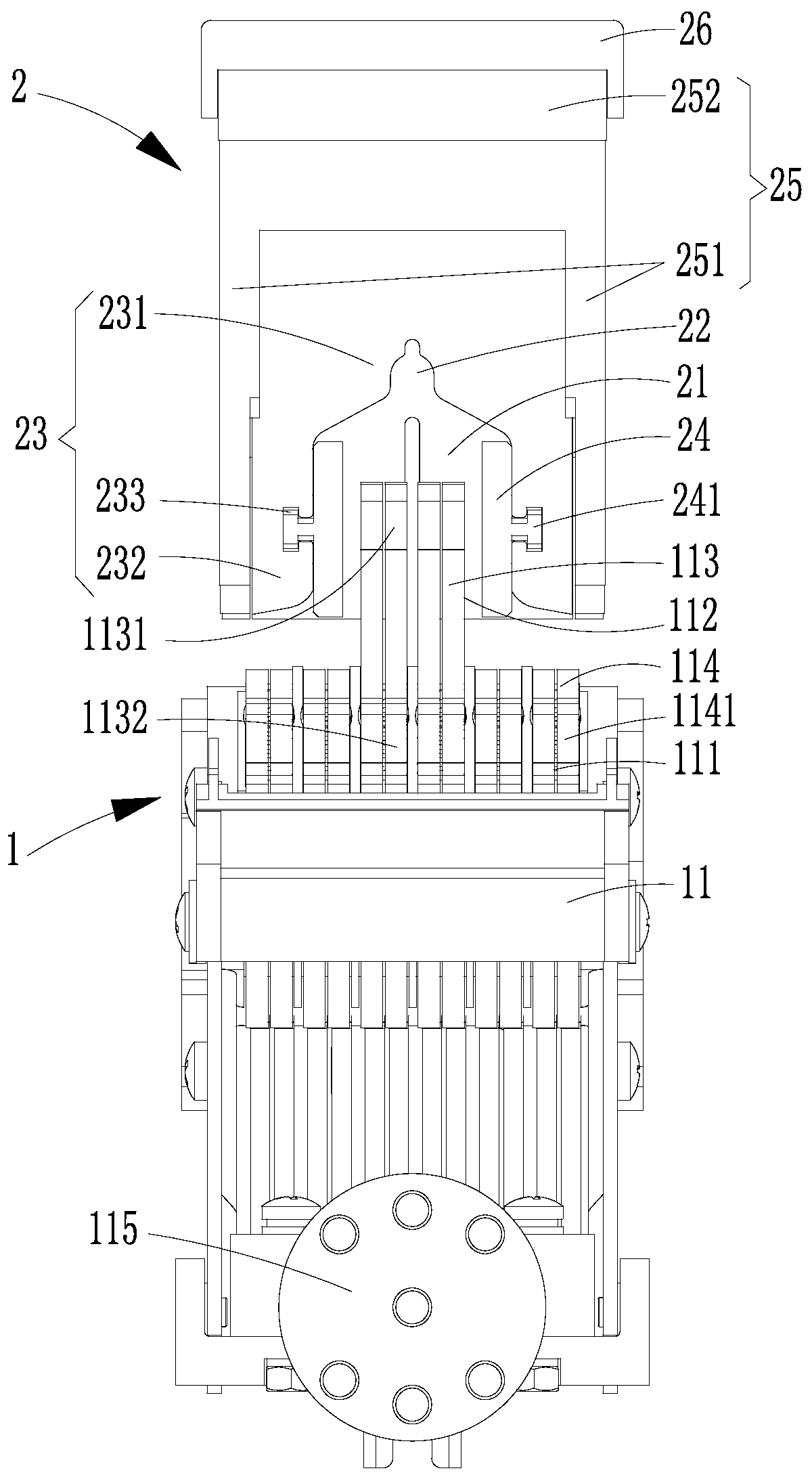

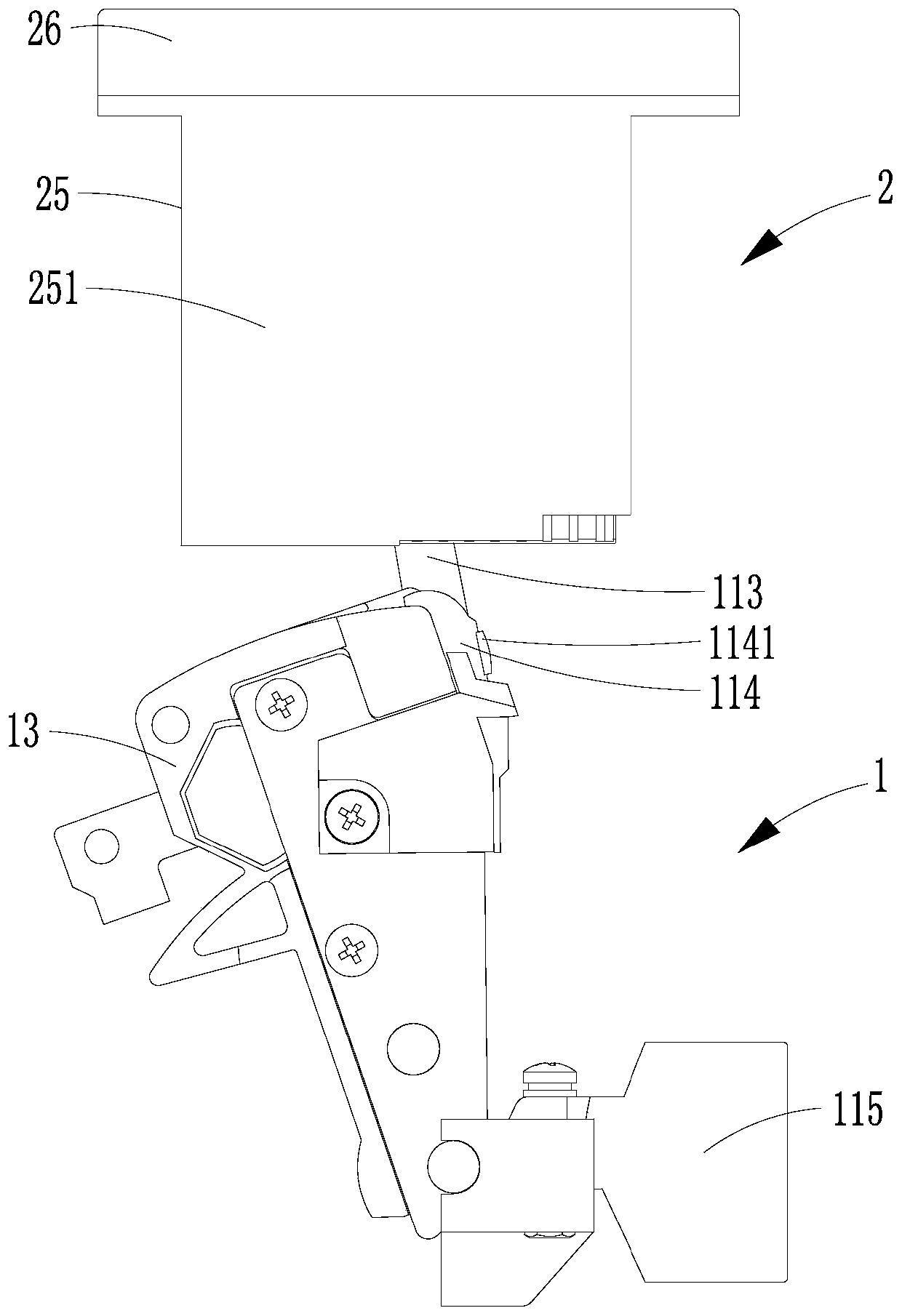

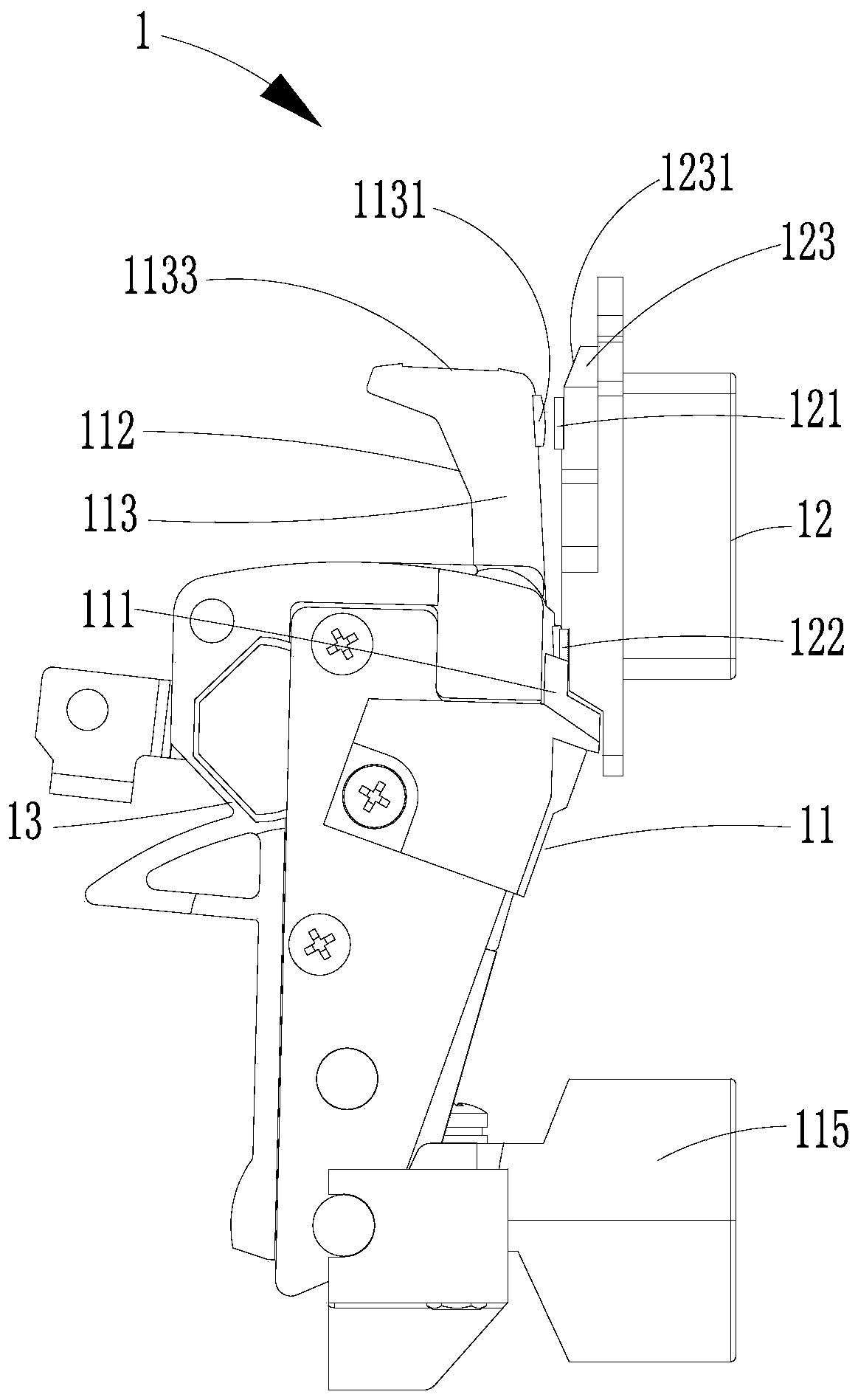

[0063] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention proposes a contact arc extinguishing system, which includes a contact system 1 and an arc extinguishing system 2; wherein:

[0064] The contact system 1 includes a movable contact 11 and a static contact 12 arranged oppositely, and the movable contact 11 has a function capable of contacting the static contact 12 (such as image 3 shown) or disconnected (as Figure 4 As shown), the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com