Testing method for fragmentation and deformation of extruded sidewall

A technology of extruding side walls and testing, applied in the direction of applying stable tension/pressure to test material strength, preparation of test samples, and measuring devices, etc., can solve the problems of less research, achieve simple operation, easy implementation, Intuitive effect of deformation behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0052] A kind of test testing method of crushing deformation of extruded side wall of the present invention, specifically implement according to the following steps:

[0053] Step 1, making an extruded side wall specimen with a trapezoidal cross-section, specifically implemented in accordance with the following steps:

[0054] Step 1.1, making mold A, using mold A and concrete to make an extruded side wall specimen;

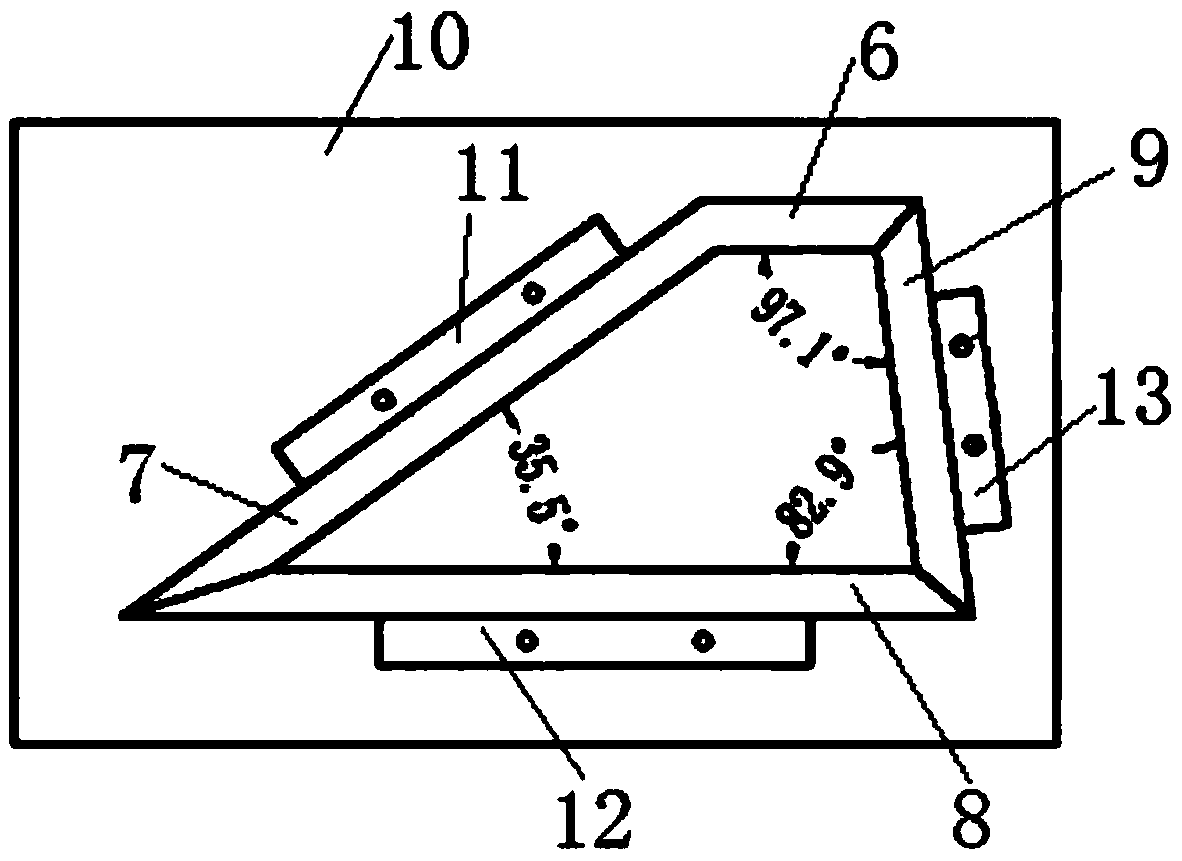

[0055] The structure of the mold A is as follows: figure 1 As shown, the base plate a10 is included, and the base plate a10 is provided with a first baffle plate 6, a second baffle plate 7, a third baffle plate 8 and a fourth baffle plate 9 which are sequentially connected end to end to form a trapezoid, and the first baffle plate 6 and the fourth baffle plate The angle between the second baffle 7 is 144.5°, the angle between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com