PVC thin film distribution device with monitoring function

A PVC film and functional technology, applied in the field of PVC film batching device, can solve the problems of sedimentation or attachment to the bottom or around the container, unscientific batching, and affecting the mixing effect, so as to improve the quality and stability, and the mixing effect is good , Improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

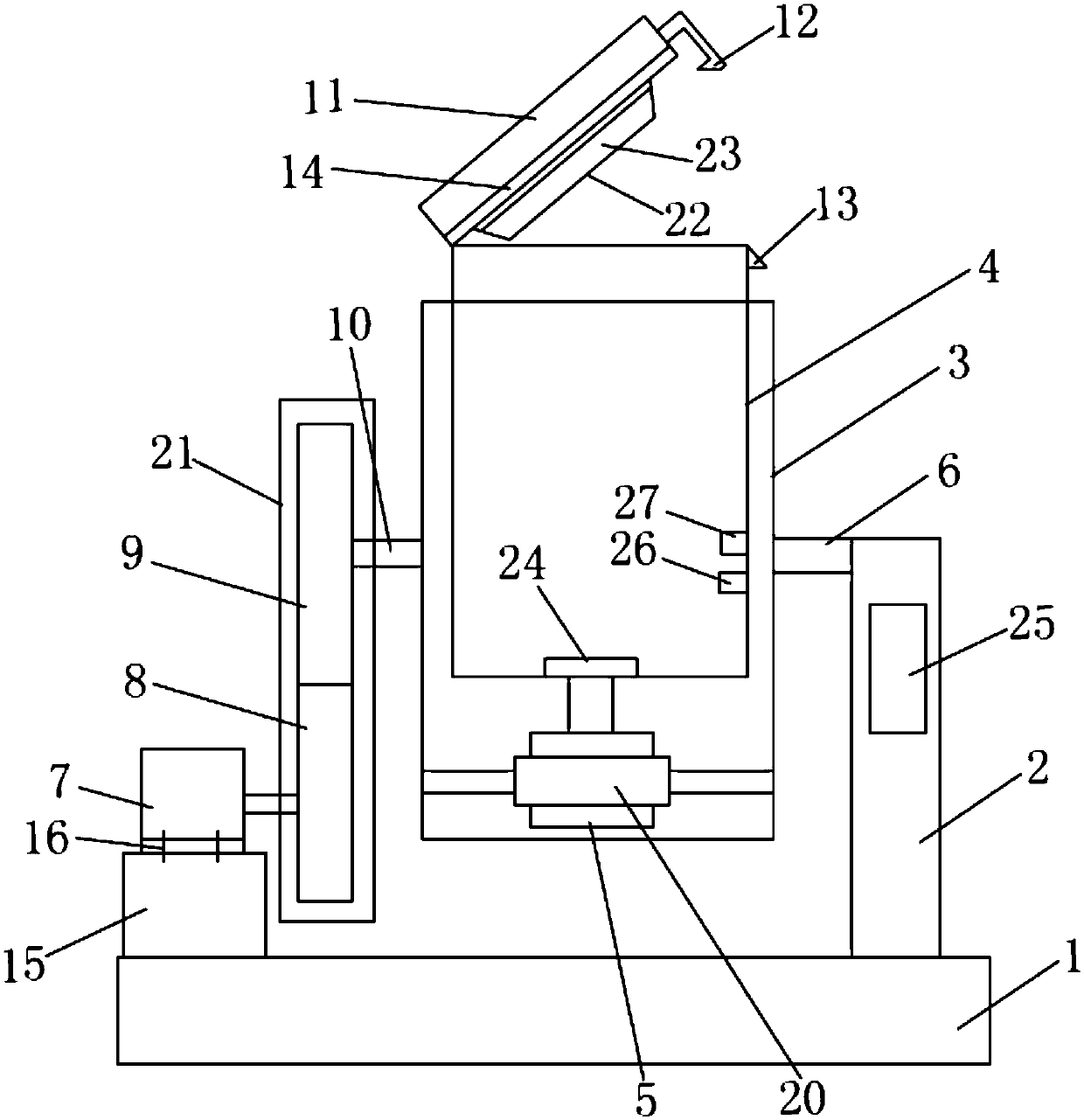

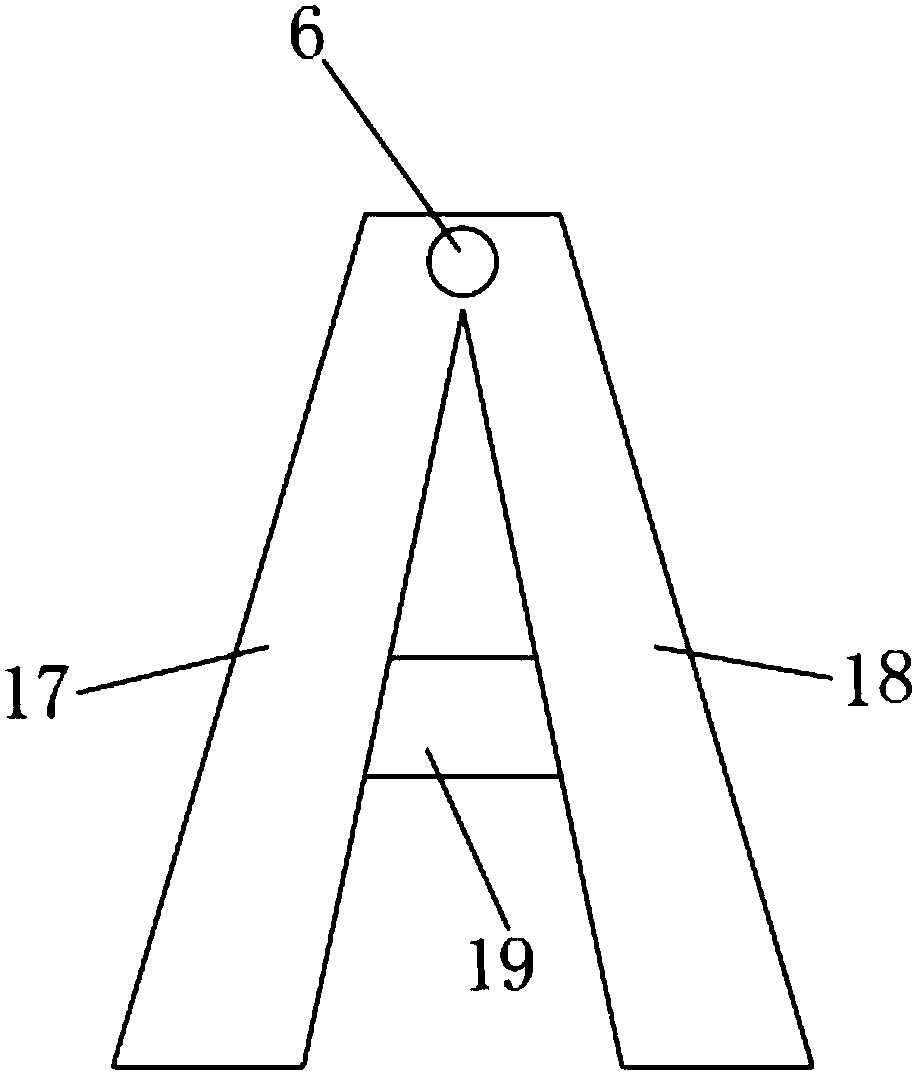

[0022] Such as figure 1 and figure 2 As shown, a PVC film batching device with a monitoring function includes a machine base 1 on which a turning power mechanism, a mixing mechanism and a support 2 are arranged. The mixing mechanism includes a housing 3, and the housing 3 is provided with The inner tank 4 is provided with a pressure sensor 24 at the bottom of the inner tank 4. The pressure sensor 24 is electrically connected to the display screen 25 arranged on the machine base 1. The pressure sensor 24 can transmit the weight of ingredients in the inner tank 4 to the display. The screen 25 shows that, in addition, a humidity sensor 26 and a temperature sensor 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com