An oil seal spring automatic blanking finishing mechanism

A technology of sorting mechanism and blanking, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of increasing defective rate and inconvenient use, and achieves the effect of reducing defective rate, improving automation and liberating labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

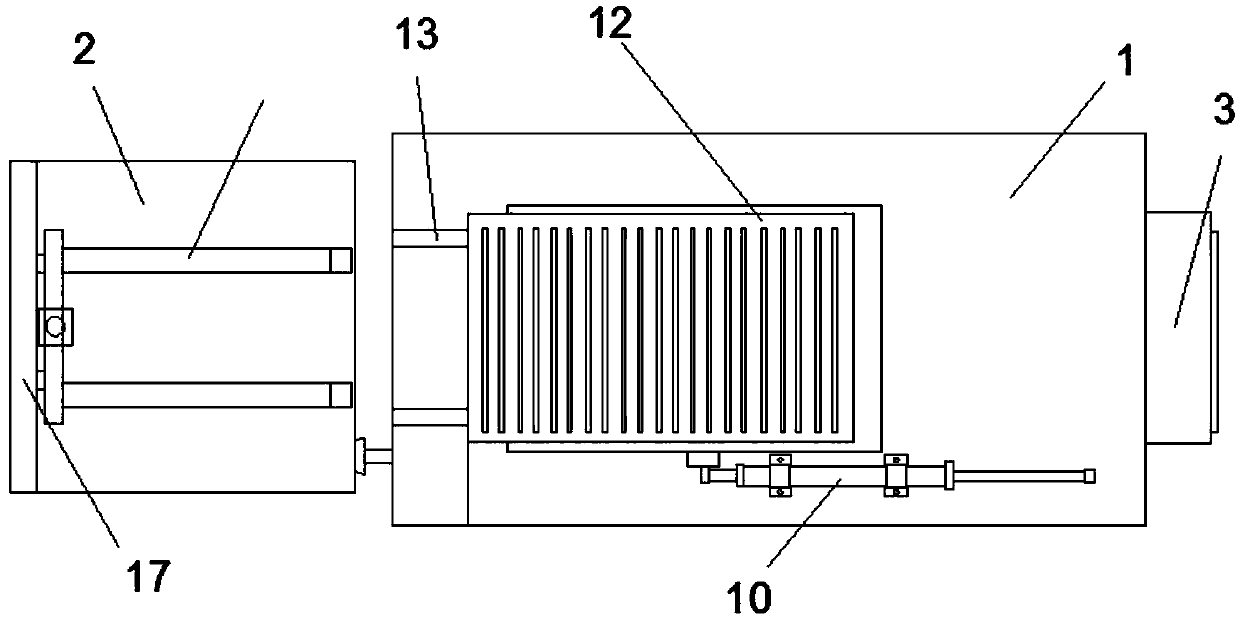

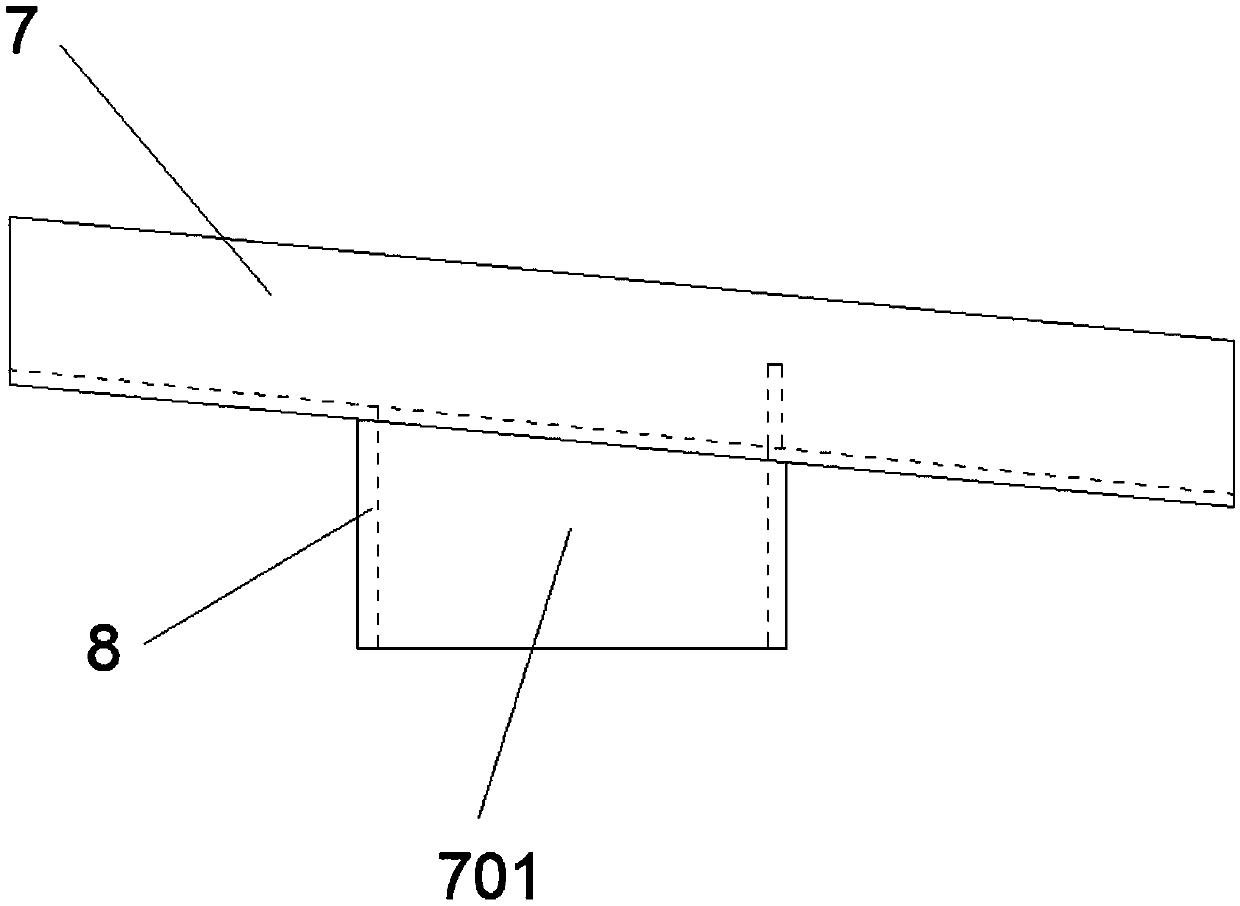

[0028] An oil seal spring automatic blanking arrangement mechanism of this embodiment, refer to Figure 1-5 : Including the first support seat 1, the second support seat 2 and the electric control cabinet 3, and also includes the blanking leveling structure 4, the first support seat 1 is equipped with a placing and conveying structure 5, and the second support seat 2 is equipped with a material tray on the top 12 Replace the structure 6. The blanking leveling structure 4 includes a V-shaped material plate 7, a shaping plate 8 and an arrangement structure 9. The V-shaped material plate 7 is fixed on the first support base 1 by a bracket, and the shaping plate 8 is vertically fixed with a V shape. On the top of the material plate 7, the arrangement structure 9 is installed obliquely at the bottom of the shaping plate 8. A blanking groove 701 is opened at the center of the top of the V-shaped material plate 7, and the blanking groove 701 penetrates the shaping plate 8; the placemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com