A kit for preparing cuboid columnar jointed rock samples

A columnar joint and sample preparation technology, which is applied in the preparation, sampling, and instrumentation of test samples, can solve the problems of unreachable powder particle size, immature 3D printing technology, test requirements and high preparation costs, and achieve test results. Improvement of sample integrity and yield, saving money, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

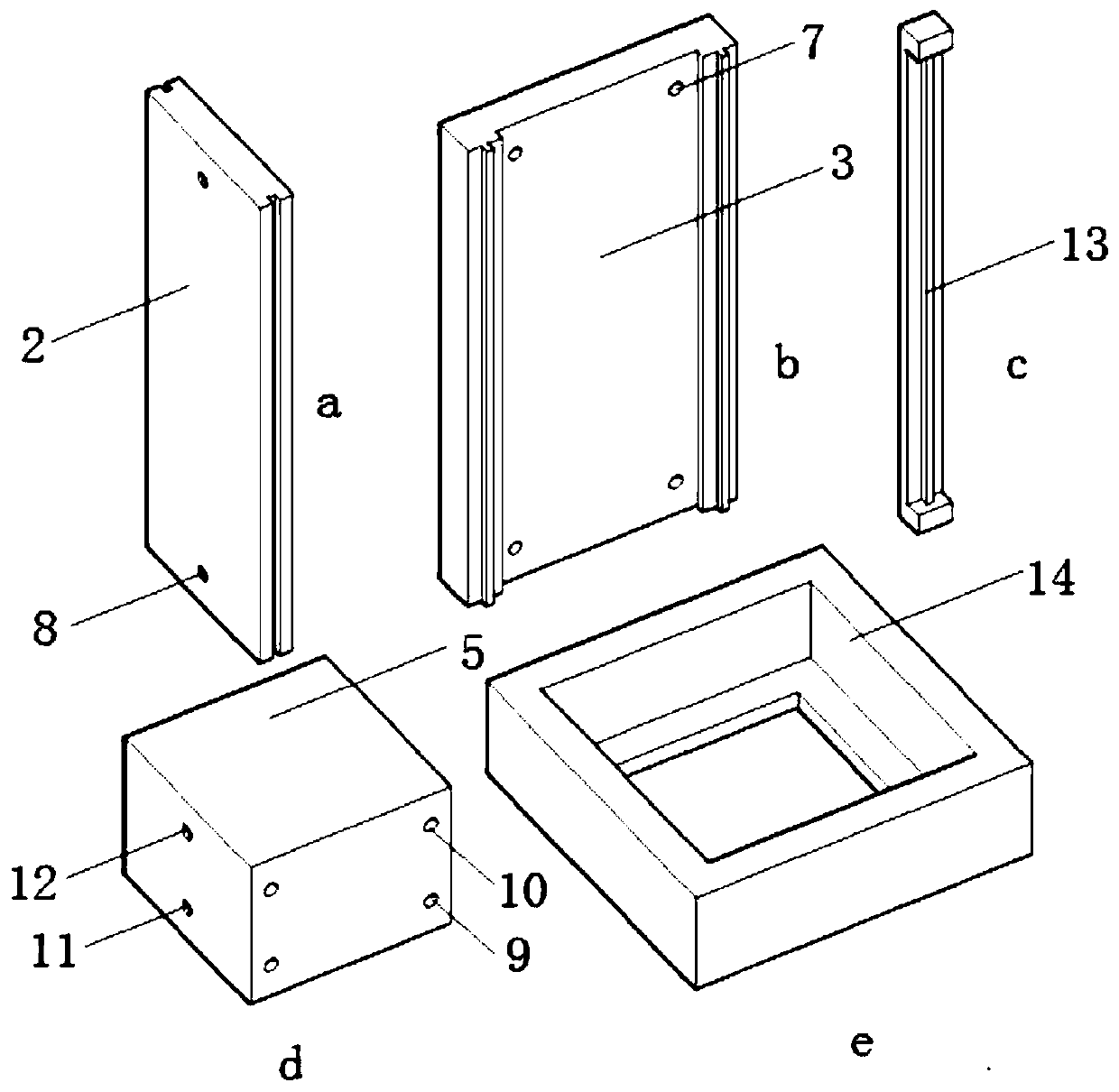

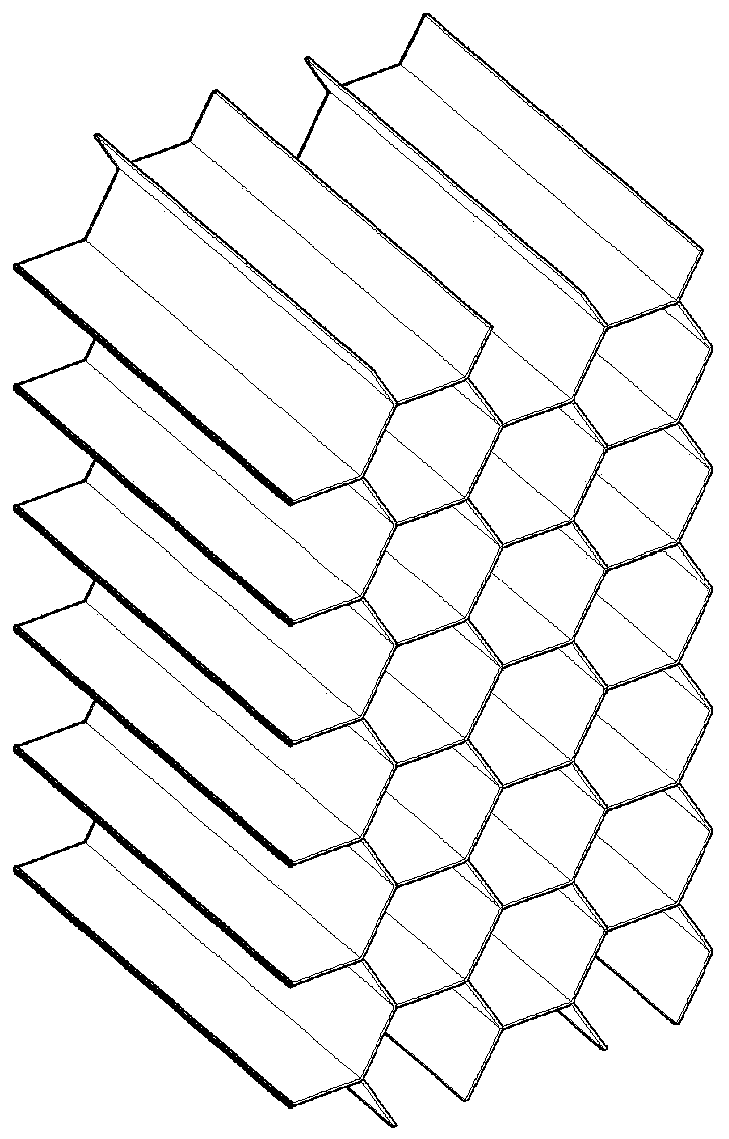

[0053] image 3 As shown, it is a 0° columnar rock mass mold made of iron powder material using 3D printing technology. Iron powder is used to control the joint thickness to 1mm through 3D printing technology, and the inclination angle of the joints in the model used is 0°. In this embodiment Just use 0° columnar rock mass mold 6 to make columnar sample.

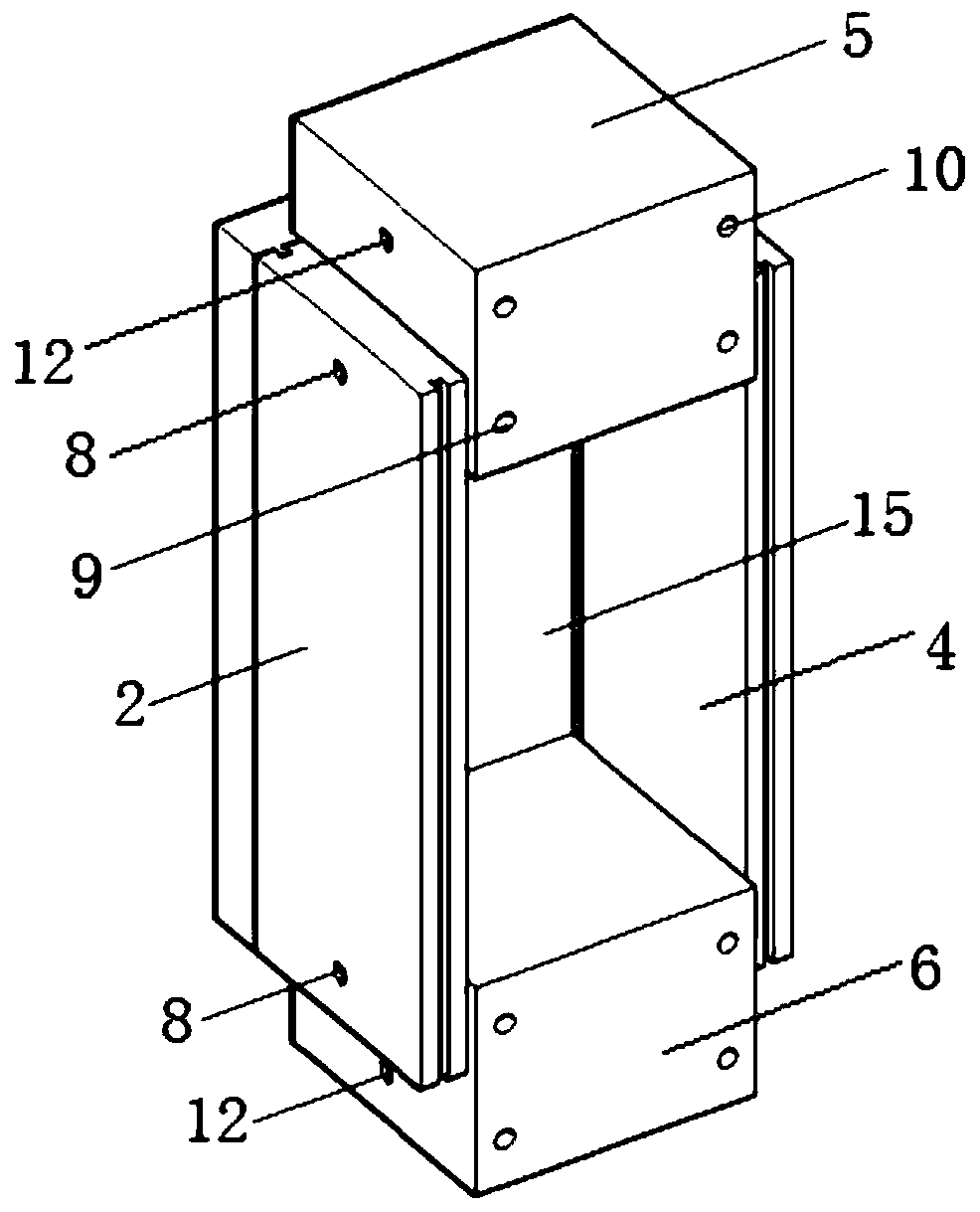

[0054] Figure 4 As shown, connect the connecting holes of the active plate near the top of the first active plate and the top of the second active plate with the connecting holes in the active plate of the first top block, and connect the connecting holes of the passive plate near the top of the first passive plate and the top of the second passive plate Connect with the connection hole in the passive plate of the first top block, remove the first active plate or the second active plate in the set, put the anti-wear clip into the concave part of the first passive plate or the second passive plate and place 0 °The columnar...

Embodiment 2

[0056] Figure 5 As shown, the position of the first active plate or the second active plate is still replaced by the anti-wear clip strip, the connection holes are connected as in Example 1, and the solidified columnar rock mass in the above-mentioned Example 1 is demoulded. Combine the prepared bonding materials in the cavity, wait for the bonding to be completely solidified, and obtain a sample block. At this time, the size of the sample block is 600×600×1100mm 3 .

Embodiment 3

[0058] Image 6 As shown, connect the first active plate, the first passive plate, the second active plate and the second passive plate in sequence, replace the first jacking block or the second jacking block with an anti-wear block, and replace the remaining second jacking block Or the first jacking block is pushed 300mm into the set, so that the connecting hole of the active plate is connected with the outer connecting hole of the active plate of the jacking block, and the connecting hole of the passive plate is connected with the outer connecting hole of the passive plate of the jacking block. Grind the 50mm of the top of the set; after one end is polished, add a top cushion block on the polished end surface of the sample block, pull out the top block on the other side and use the anti-wear block to replace the sample Push the block into the inside of the set, so that the connecting hole of the active plate is connected with the outer connecting hole of the active plate of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com