Steel casing arrangement device for sand foundation cast-in-place pile drilling and construction method of steel casing arrangement device

A sandy soil foundation and steel casing technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of uneven stress on steel casings and easy tilting, so as to improve construction quality and avoid resetting , the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

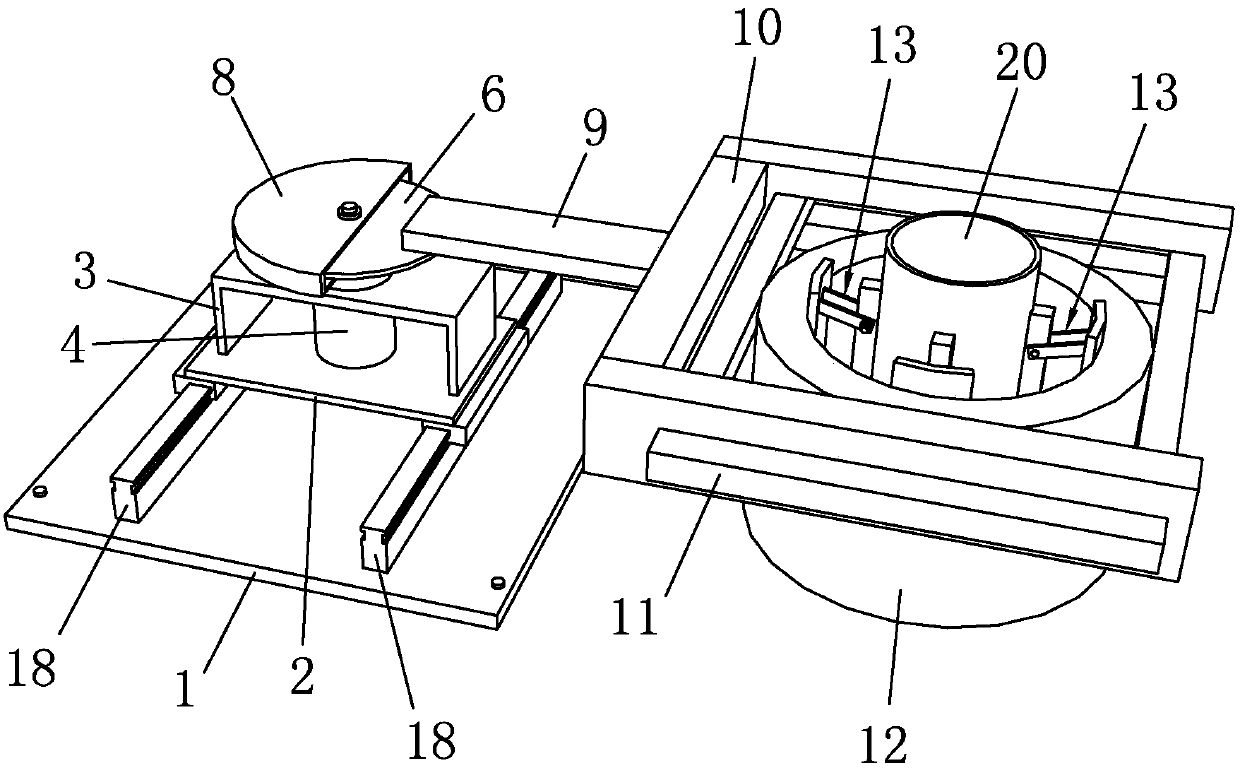

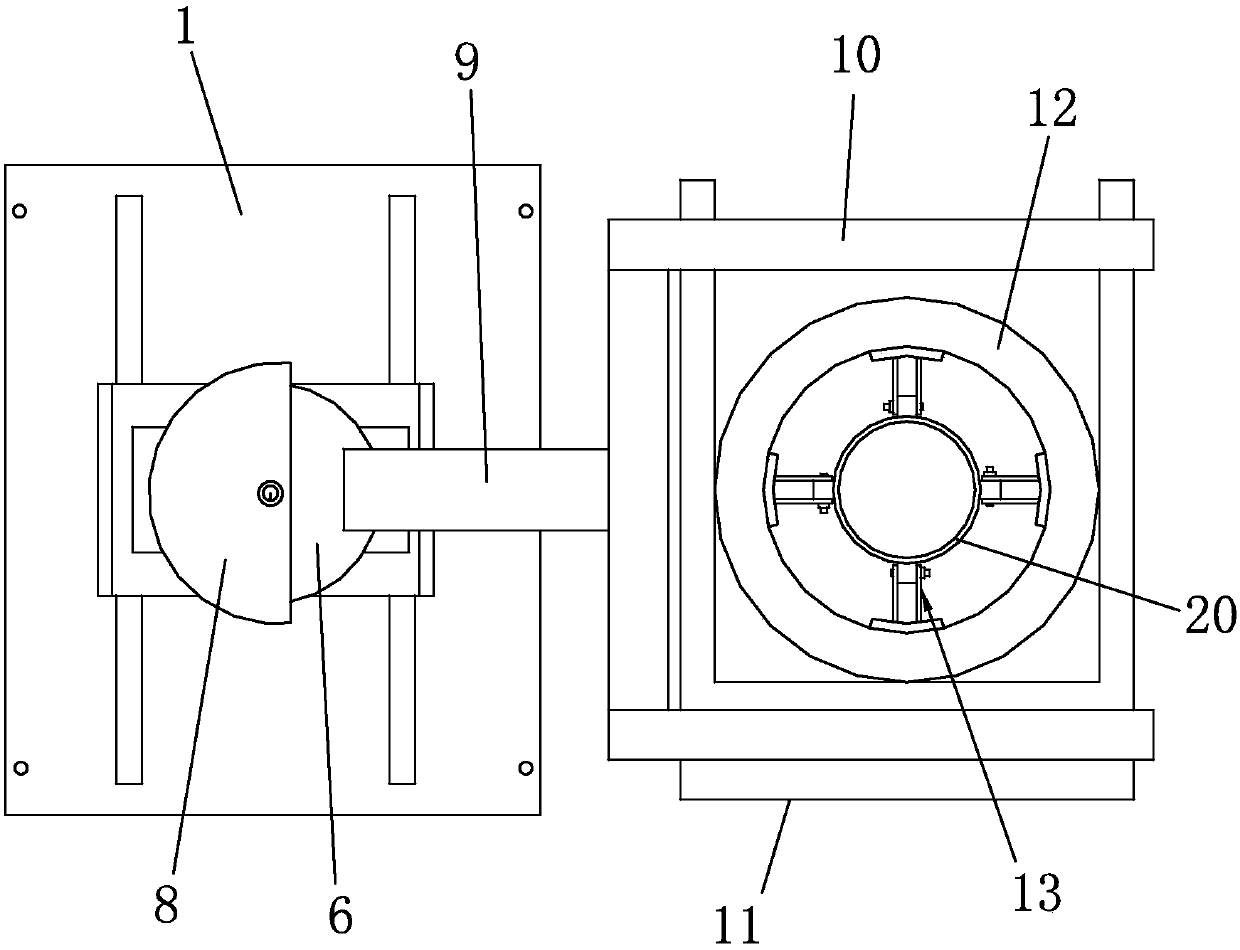

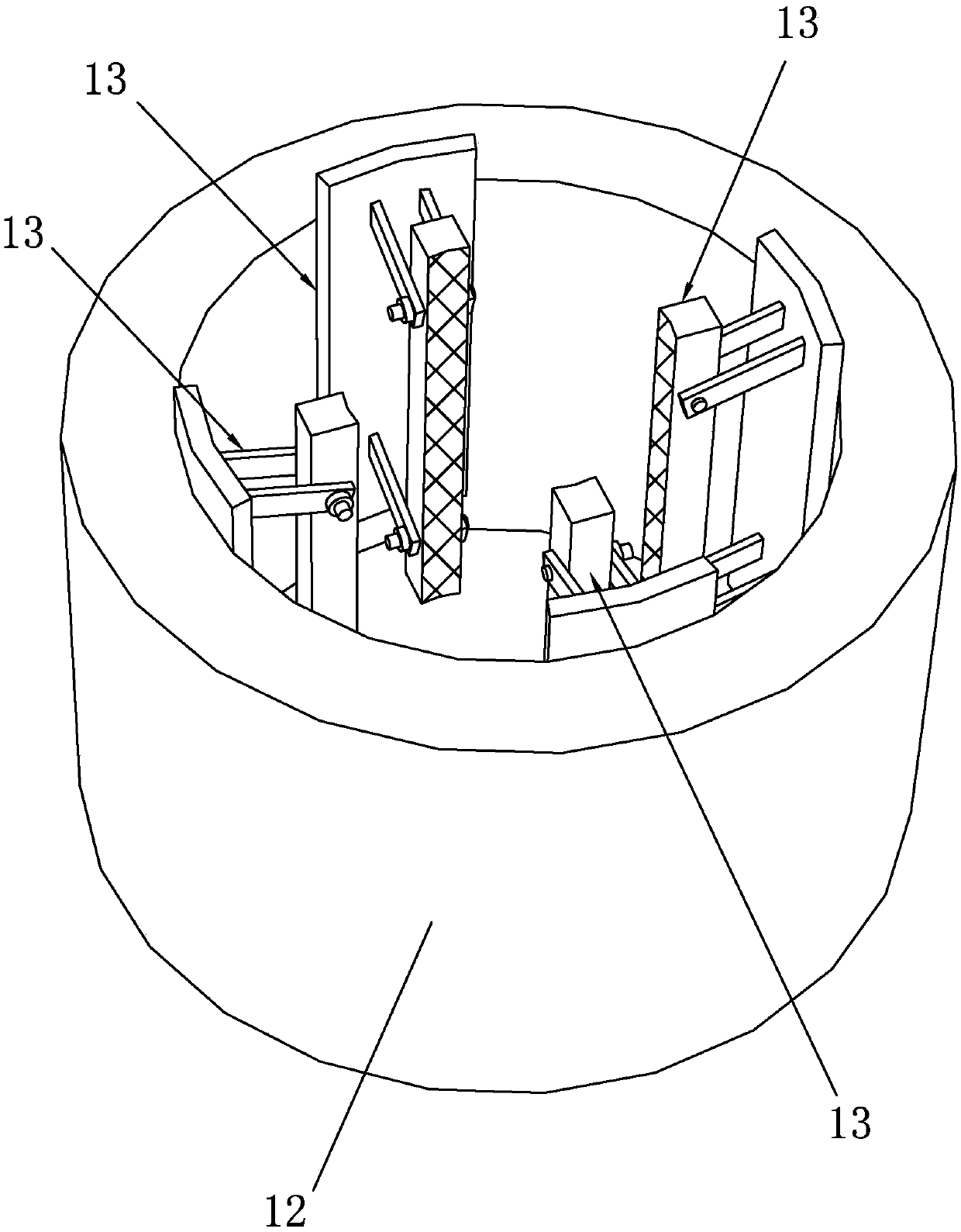

[0032] like Figure 1 to Figure 5 As shown, it is the installation device for the steel casing of the present invention for the drilling of cast-in-place piles in sandy soil foundation, including the embedded steel plate 1 and the guide cylinder 20, the embedded steel plate 1 is slidably connected with the moving plate 2, and the embedded steel plate 1 is provided with a guide rail 18 , the bottom of the moving plate 2 is provided with a slider 19 , and the slider 19 is slidably connected to the guide rail 18 . Moving plate 2 is provided with support frame 3, and support frame 3 is provided with rotating device 4, and rotating device 4 is located at the top surface place of moving plate 2, and rotating device 4 is provided with rotating shaft 5, and rotating shaft 5 is connected with disc 6 in rotation. The top of the support frame 3 is provided with a leveling rod 7, and the top of the leveling rod 7 is provided with a rotating housing 8, and the disc 6 is rotatably connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com