External reinforcement method of blade and blade used for wind power generating set

A technology of external reinforcement and reinforcement, which is applied in wind turbines, wind power generation, engines, etc., can solve problems such as the mismatch between the aerodynamic performance of the blade and the design value, non-conformity, and non-conformity of the external reinforcement surface of the blade, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be described in detail below with reference to the drawings.

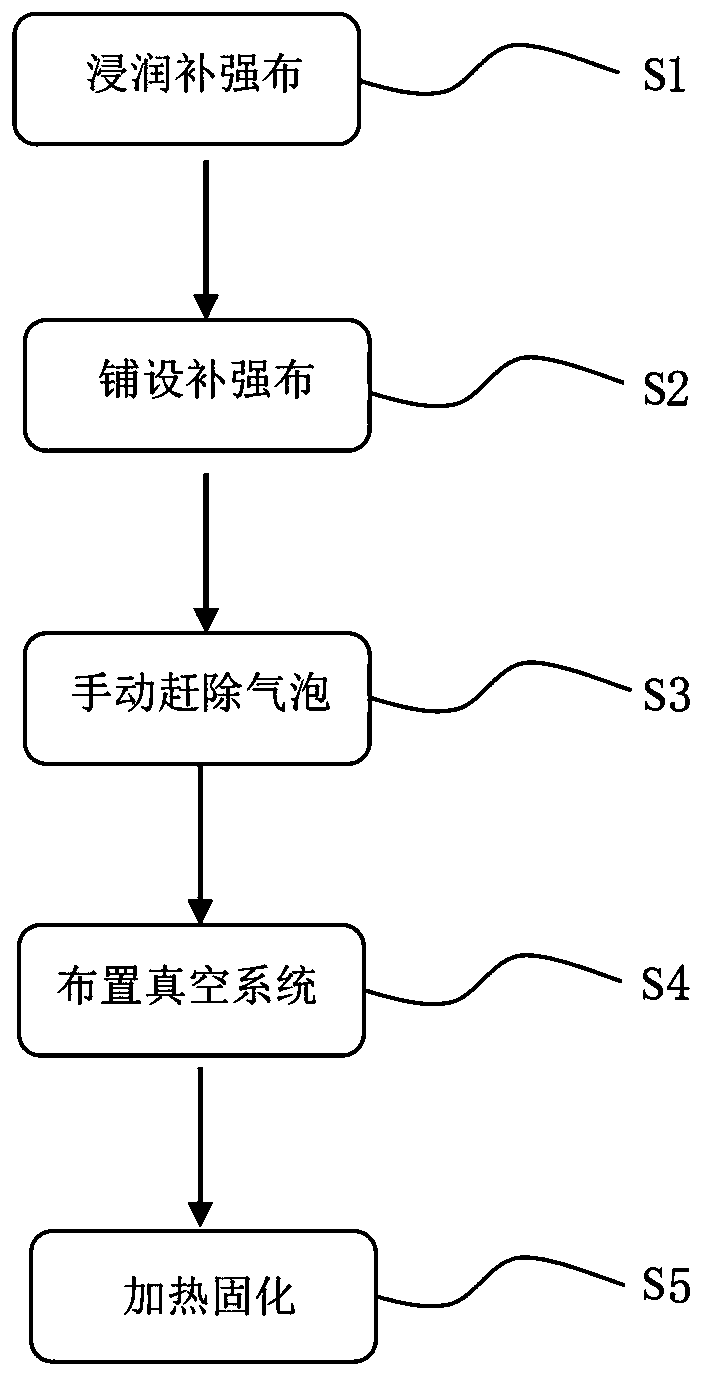

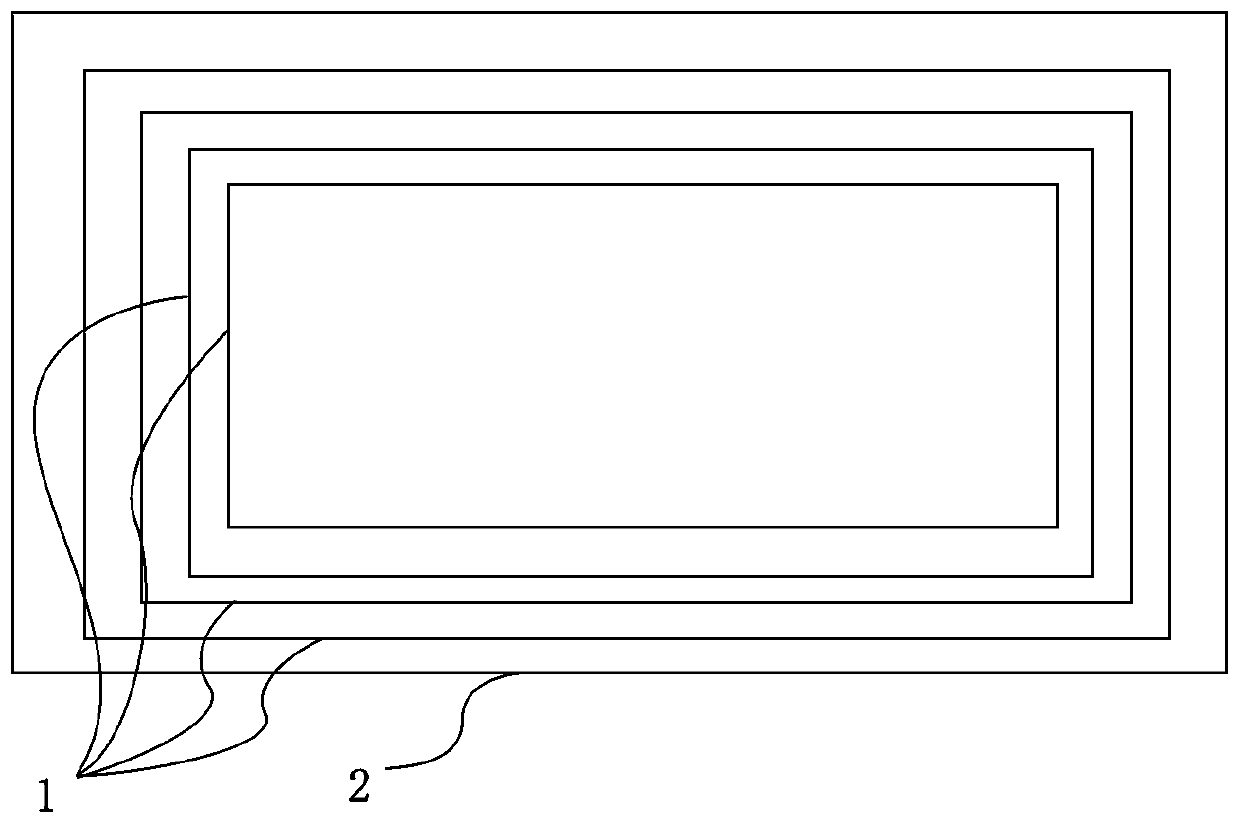

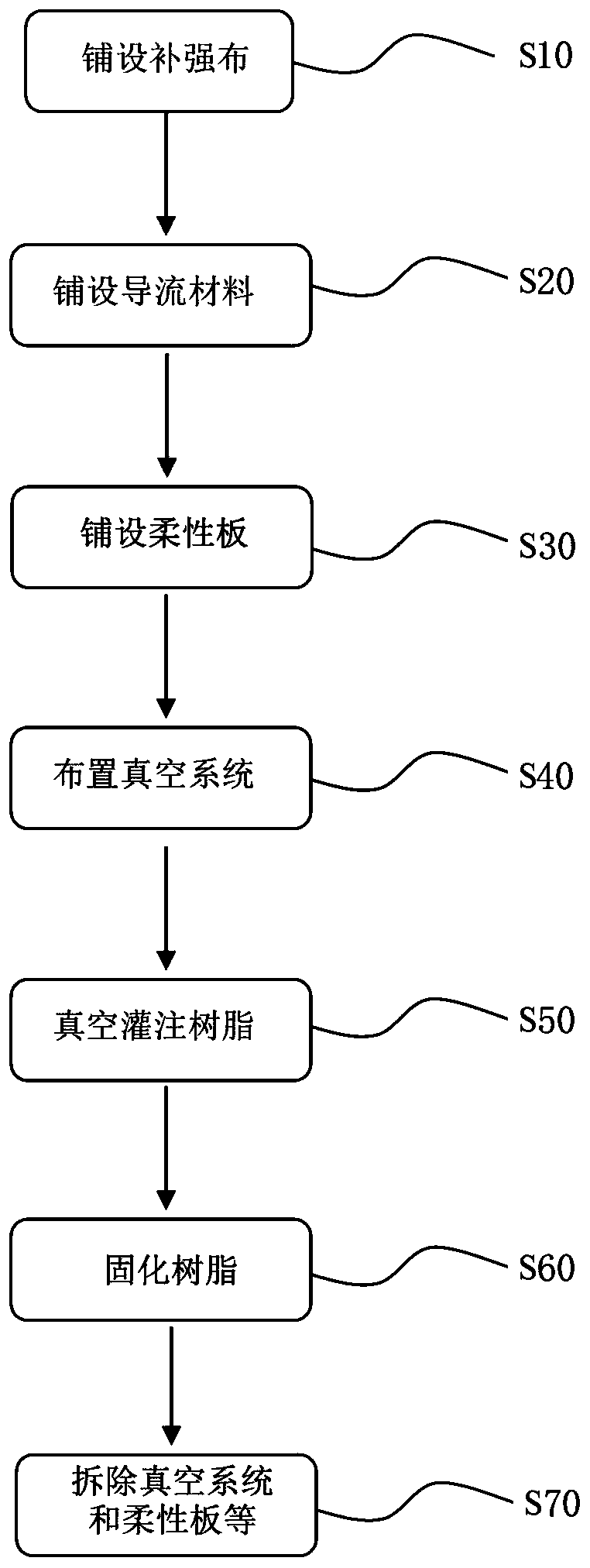

[0024] image 3 is a flowchart of a blade external reinforcement method according to an exemplary embodiment of the present invention, Figure 4 It is a schematic diagram of the arrangement of the reinforcement cloth of each layer in the external reinforcement method of the blade according to the exemplary embodiment of the present invention.

[0025] Such as image 3 As shown, the method for external reinforcement of a blade according to an exemplary embodiment of the present invention includes: laying the reinforcing cloth 10 layer by layer on the position to be reinforced of the blade (S10); covering the outer side of the reinforcing cloth with a flexible plate 20 (S30); arrange the vacuum system 30 (S40) on the outside of the flexible board 20; evacuate and pour the resin (S50) after vacuuming; make the resin solidify and form (S60); remove the vacuum system (3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com