Cavitation-resistant structure surface layer

A technology of structural surface and surface layer, used in propellers, mechanical equipment, valve devices, etc., can solve problems such as failure and reduced turbine mechanical efficiency, and achieve reduced cavitation damage, good anti-cavitation effect, and easy assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

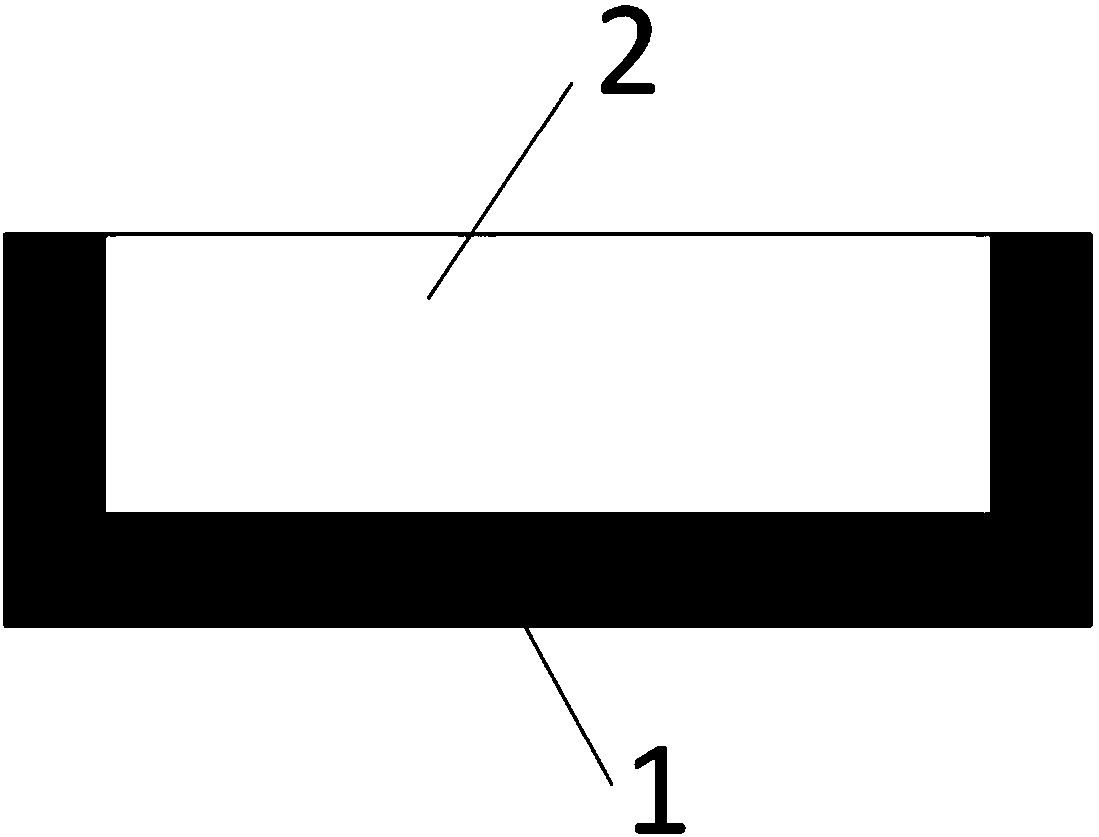

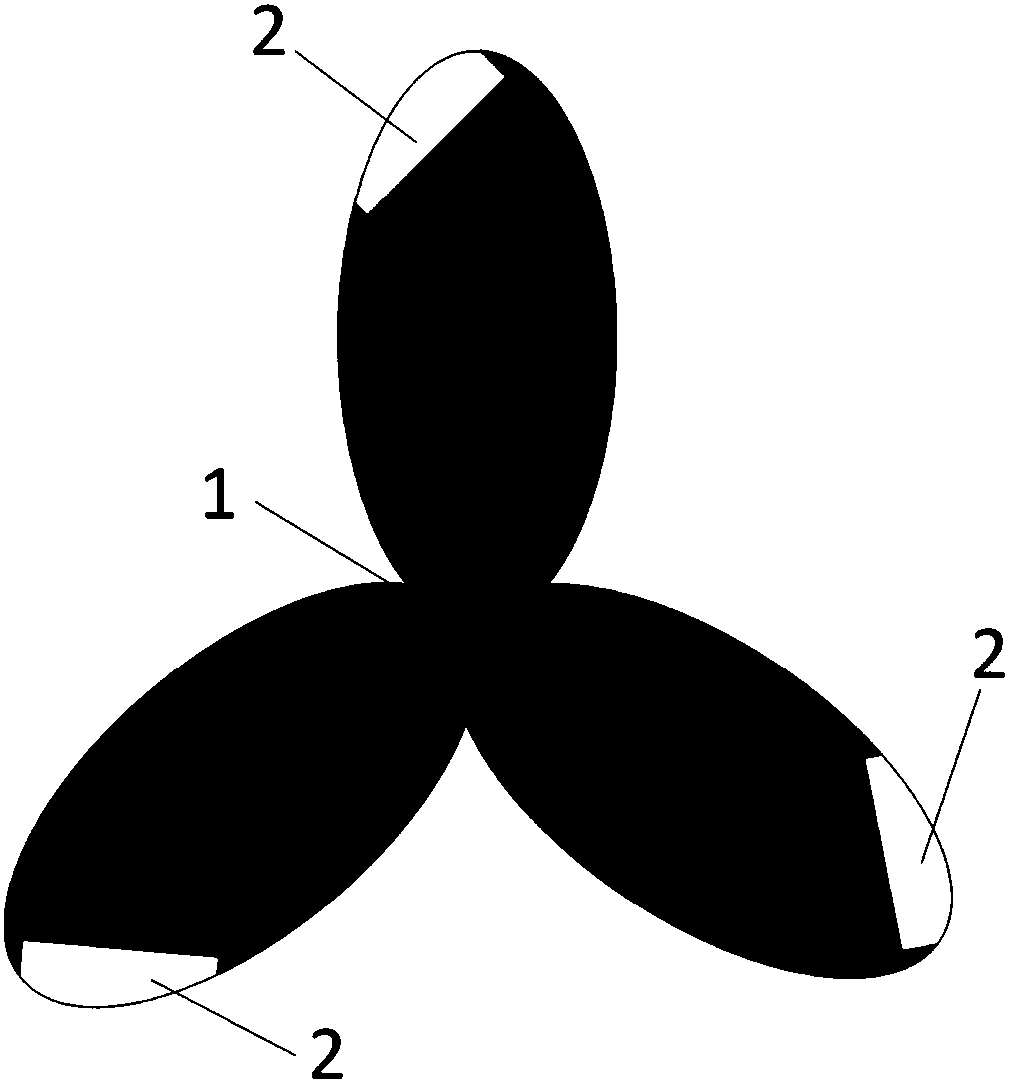

[0027] Such as figure 2 As shown, the surface layer comprises a substrate 1 and a layer 2 of elastic material. The base 1 is a propeller, and the layer of elastic material is arranged on the surface of the propeller at the lowest pressure part away from the incoming flow direction.

[0028] The propeller is slotted, and the elastic material layer is a piece of rubber, which is embedded in the slot of the propeller.

[0029] During the implementation, the water flow is impacted and passed through the propeller. After testing, it is found that:

[0030] In the absence of the elastic material layer, the cavitation bubble collapsing jet forms cavitation erosion towards the propeller surface.

[0031] When the elastic material layer exists, the cavitation bubble collapse jet deviates from the elastic surface of the propeller, avoiding cavitation erosion.

Embodiment 2

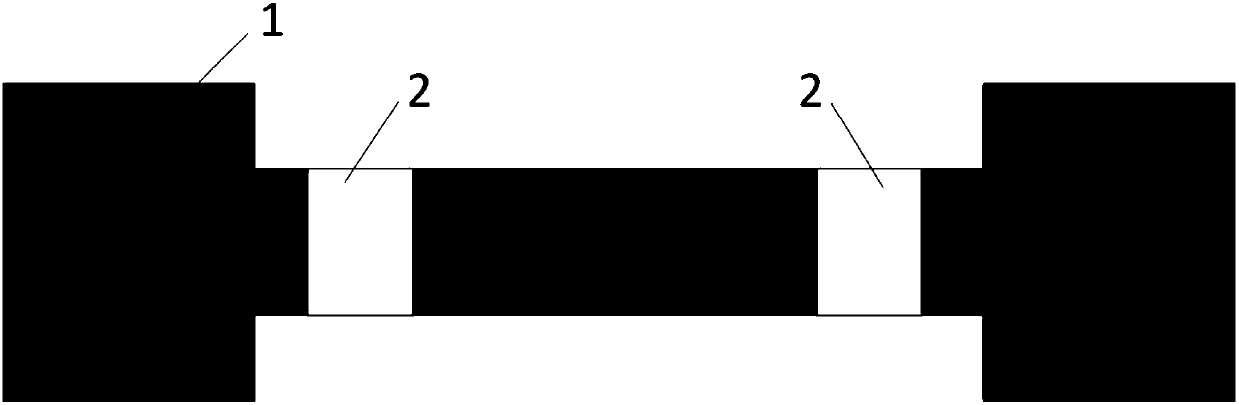

[0033] Such as image 3 As shown, the surface layer comprises a substrate 1 and a layer 2 of elastic material. The base 1 is the valve core, and the elastic material layer is arranged on the surface of the lowest pressure part of the valve core.

[0034] In the valve, an annular groove is formed on the surface of the valve core facing the liquid inlet, and the elastic material layer is an annular rubber, which is embedded in the annular groove of the valve core.

[0035] During the implementation, the water flow is impacted and passed through the valve core. After testing, it is found that:

[0036] In the absence of the elastic material layer, the cavitation bubble collapsing jet forms cavitation towards the surface of the valve core.

[0037] When the elastic material layer exists, the cavitation bubble collapse jet deviates from the elastic surface of the valve core to avoid cavitation erosion.

[0038] It can be seen that the structure of the present invention is very s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com