A rare earth ore crushing and screening device

A technology of crushing and screening, rare earth ore, applied in separation methods, filtration and separation, dry gas arrangement, etc., can solve the problems of ineffective recovery of heat, low environmental friendliness, etc., and achieve the effect of compact production flow and slow down damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

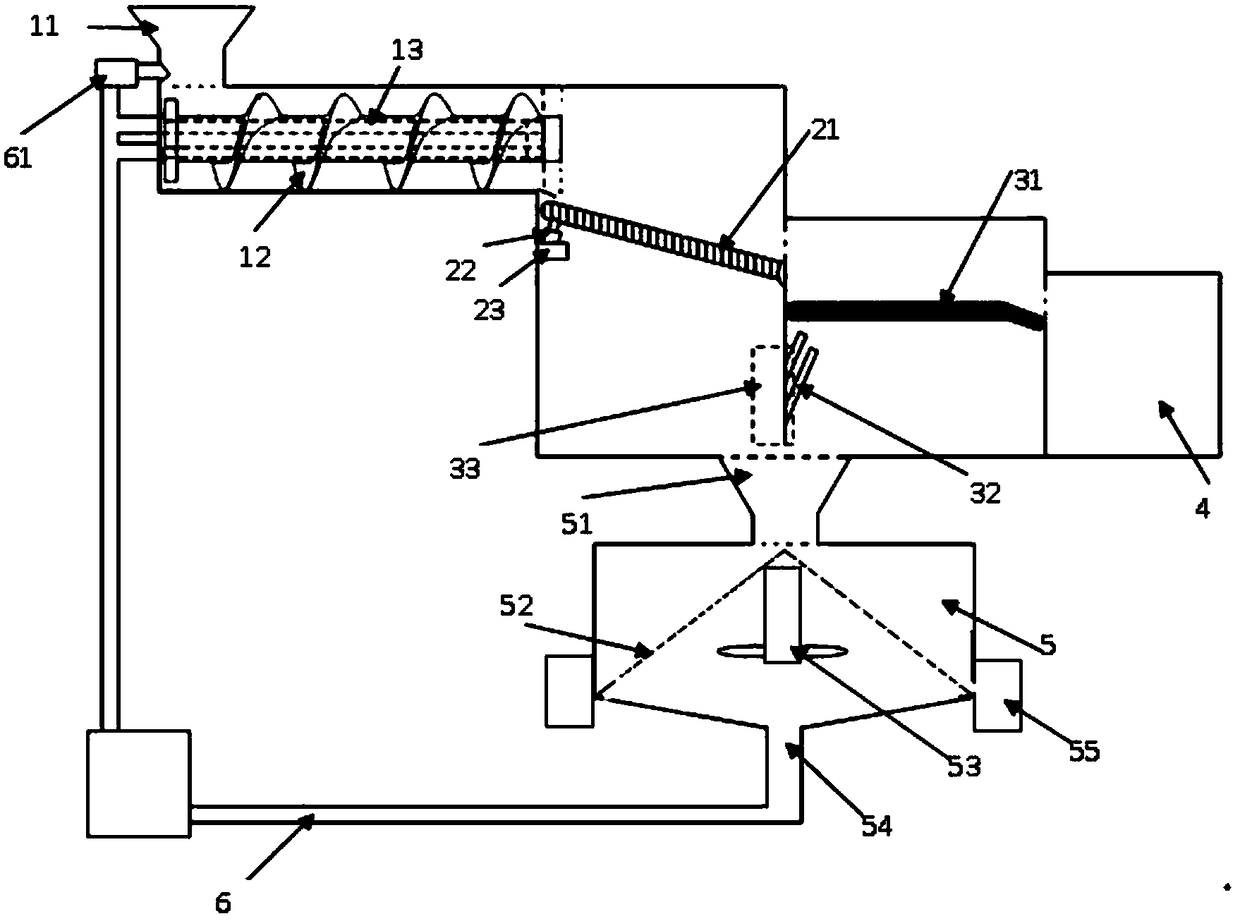

[0026] like figure 1 as shown,

[0027] A rare earth ore crushing and screening device includes a crushing transmission chamber, a solid-liquid separation chamber, a drying preheating chamber, a temporary storage box for ore fine particles, a sewage filtering chamber and a water circulation system.

[0028] The crushing transmission chamber includes a casing I, an ore inlet, a crushing transmission shaft and a water-cooling pipeline; the ore inlet is arranged on the top of the casing I and is in the shape of a funnel for inputting primary crushed ore into the crushing transmission chamber. A water spray nozzle is provided at the entrance; the crushing transmission shaft includes a rotating shaft and a single helical blade arranged on the rotating shaft; a serpentine water-cooling pipeline is arranged inside the rotating shaft; a crushing transmission chamber is provided at the terminal of the crushing transmission shaft The outlet of the crushing transfer chamber is connected...

Embodiment 2

[0042] A rare earth ore crushing and screening device includes a crushing transmission chamber, a solid-liquid separation chamber, a drying preheating chamber, a temporary storage box for ore fine particles, a sewage filtering chamber and a water circulation system.

[0043] The crushing transmission chamber includes a casing I, an ore inlet, a crushing transmission shaft and a water-cooling pipeline; the ore inlet is arranged on the top of the casing I and is in the shape of a funnel for inputting primary crushed ore into the crushing transmission chamber. A water spray nozzle is provided at the entrance; the crushing transmission shaft includes a rotating shaft and a single helical blade arranged on the rotating shaft; a serpentine water-cooling pipeline is arranged inside the rotating shaft; a crushing transmission chamber is provided at the terminal of the crushing transmission shaft The outlet of the crushing transfer chamber is connected with the inlet of the solid-liquid...

Embodiment 3

[0057] A rare earth ore crushing and screening device includes a crushing transmission chamber, a solid-liquid separation chamber, a drying preheating chamber, a temporary storage box for ore fine particles, a sewage filtering chamber and a water circulation system.

[0058] The crushing transmission chamber includes a casing I, an ore inlet, a crushing transmission shaft and a water-cooling pipeline; the ore inlet is arranged on the top of the casing I and is in the shape of a funnel for inputting primary crushed ore into the crushing transmission chamber. A water spray nozzle is provided at the entrance; the crushing transmission shaft includes a rotating shaft and a single helical blade arranged on the rotating shaft; a serpentine water-cooling pipeline is arranged inside the rotating shaft; a crushing transmission chamber is provided at the terminal of the crushing transmission shaft The outlet of the crushing transfer chamber is connected with the inlet of the solid-liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com