A fully automatic control system and control method for a continuous production kiln

A control system and continuous technology, applied in furnace control devices, furnaces, furnace components, etc., can solve the problems of high labor cost, affect product quality, time-consuming and laborious, and achieve consistent firing quality and ensure firing quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

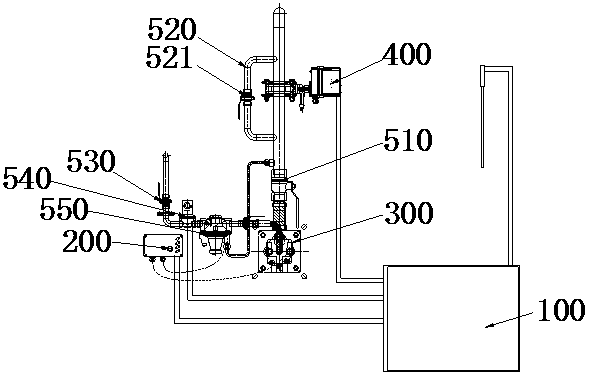

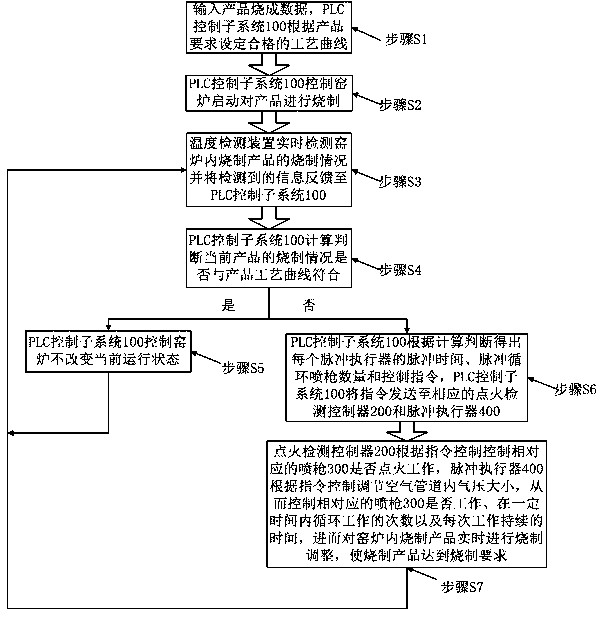

[0037] Such as figure 1 As shown, a fully automatic control system for a continuous production kiln, including:

[0038] Continuous production of kiln body;

[0039] A PLC control subsystem 100 that controls the automatic operation of the entire continuous production kiln body;

[0040] A plurality of temperature detection devices for detecting the real-time temperature of the fired product and feeding it back to the PLC control subsystem 100;

[0041] A plurality of ignition detection controllers 200 for performing ignition actions and monitoring flames;

[0042] A plurality of spray guns 300 for spraying flames generated by gas combustion into the kiln;

[0043] The pulse actuator 400 is used to adjust the air pressure in the air d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com