Molten-salt single-tank electric heating heat storage heating system and using method

A heating system and electric heating technology, applied in heating methods, heating systems, and central heating, can solve the problems of tank space not being utilized, and achieve the effects of alleviating smog, reducing peak-to-valley differences, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

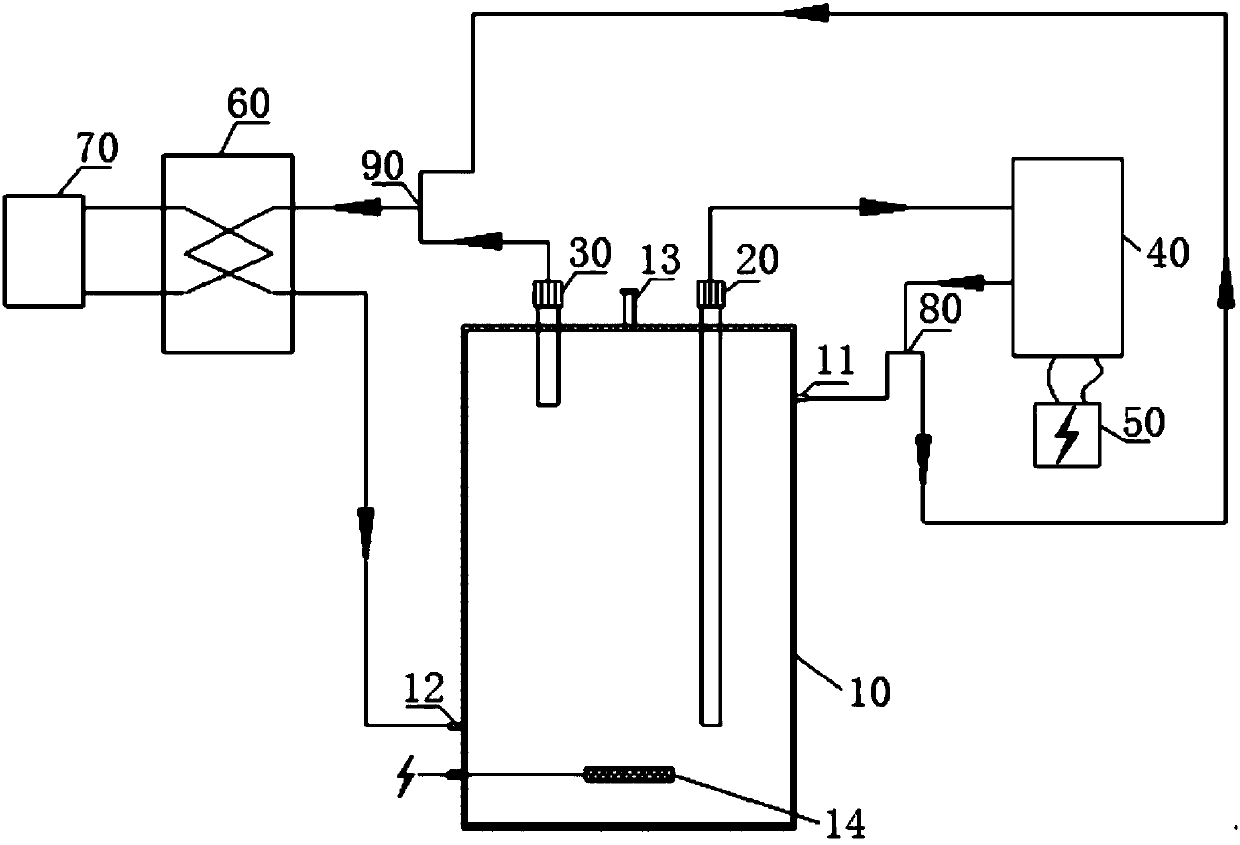

[0038] Such as figure 1 As shown, the present invention provides a molten salt single-tank electric heating heat storage heating system, including: a molten salt heat storage tank 10, an electric heating device 14, a low-temperature molten salt pump 20, a high-temperature molten salt pump 30, and a molten salt electric heater 40. Power supply 50, heat exchanger and heat user 70. The heat exchanger in this embodiment is a molten salt-water heat exchanger 60. The molten salt-water heat exchanger 60 includes a molten salt side and a water side, and the molten salt side includes The molten salt side inlet and the molten salt side outlet of the molten salt-water heat exchanger 60, the water side includes the water side inlet and the water side outlet of the molten salt-water heat exchanger 60; wherein:

[0039] The molten salt heat storage tank 10 of the present invention is used to store the heat storage medium molten salt, and other heat storage media can also be used to replace ...

Embodiment 2

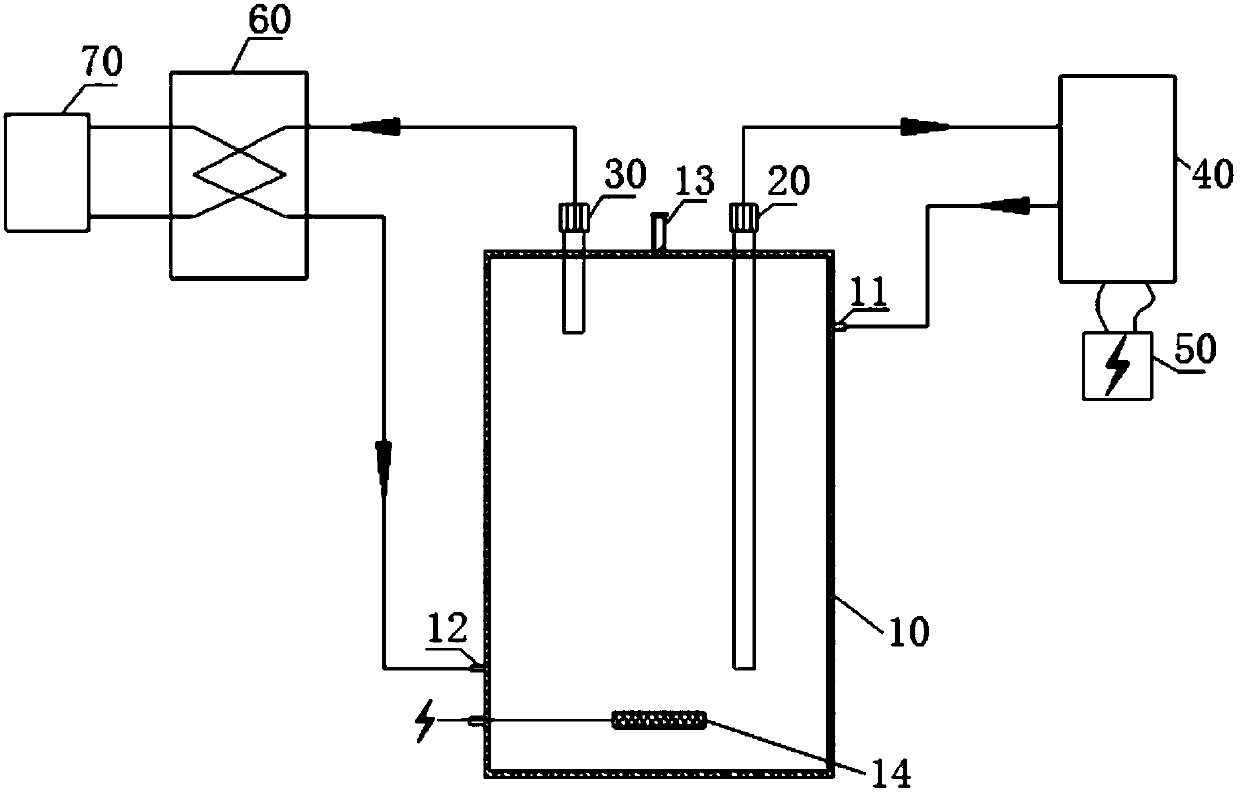

[0052] Such as figure 2 As shown, the present invention provides a molten salt single-tank electric heating thermal storage heating system, which is similar to Embodiment 1, except that the pipeline connecting the outlet of the molten salt electric heater to the molten salt inlet of the heat exchanger is omitted, and other Structure is identical with embodiment 1. Specifically:

[0053] The molten salt heat storage tank 10 of the present invention is provided with a low-temperature molten salt pump 20 for extracting low-temperature molten salt from the lower part of the molten salt heat storage tank 10 (top). Below, the outlet of the low-temperature molten salt pump 20 is connected to the molten salt inlet of the molten salt electric heater 40, the molten salt outlet of the molten salt electric heater 40 is connected to the high-temperature molten salt inlet 11, and the molten salt electric heater 40 is connected to the power supply 50 The power supply 50 is the "garbage el...

Embodiment 3

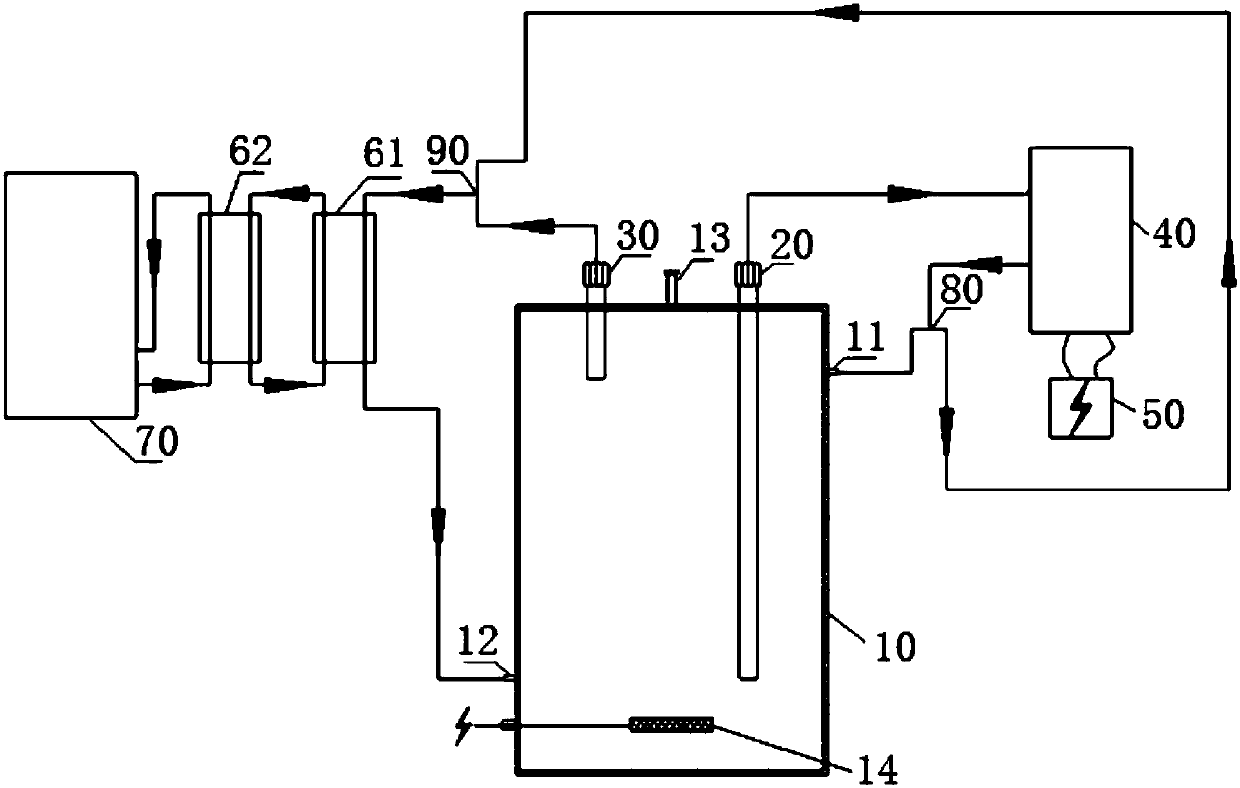

[0063] Such as image 3 As shown, the present invention provides a molten salt single-tank electric heating thermal storage heating system, which is similar to Embodiment 1, except that the molten salt-water heat exchanger 60 is replaced by a molten salt-steam heat exchanger 61 connected in series It is connected with the steam-water heat exchanger 62, the molten salt-steam heat exchanger 61 is connected with the third interface of the heating tee pipe 90, the steam-water heat exchanger 62 is connected with the heat user 70, other structures and usage methods are the same as the embodiment 1 is the same. This embodiment adds a heat exchange process, which can reduce the temperature difference of the heat exchanger, increase the service life of the heat exchanger, and is beneficial to the safe operation of the system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com