A kind of active coke and its preparation method

A technology of active coke and active gas, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of long process route, high production cost, serious pollution, etc., and achieve good desulfurization effect, good stability, and active high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0053] The method for preparing active coke of the present invention comprises:

[0054] (1) The semi-coke is successively contacted with hydrochloric acid and hydrofluoric acid solutions to obtain deashed semi-coke;

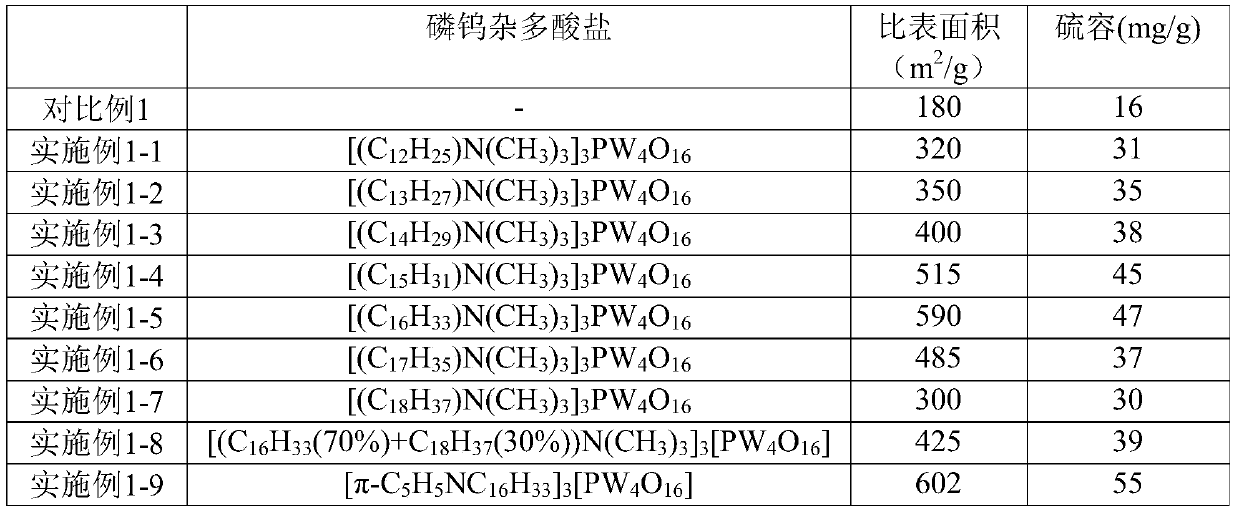

[0055] (2) In the presence of peroxide, the delimed semi-coke is contacted with phosphotungstic heteropoly salt to obtain oxidized semi-coke;

[0056] (3) heating the oxidized semi-coke for activation to obtain active coke.

specific Embodiment approach 2

[0057] The method for preparing active coke of the present invention comprises:

[0058] (1) crushing the raw material semi-coke, and then drying the pulverized raw material semi-coke at 120-140° C. for 2-4 hours to obtain the semi-coke;

[0059] (2) contacting the semi-coke with hydrochloric acid and hydrofluoric acid solution in turn to obtain deashed semi-coke;

[0060] (3) In the presence of peroxide, contacting the delimed semi-coke with phosphotungstic heteropoly acid salt to obtain oxidized semi-coke;

[0061] (4) heating the oxidized semi-coke for activation to obtain active coke.

[0062] In the above-mentioned specific embodiment 1 and specific embodiment 2, the substances involved, their dosages and reaction conditions are the same as those described above in the present invention, and the present invention will not repeat them here.

[0063] In a second aspect, the present invention provides active coke prepared by the aforementioned method.

[0064] The present...

preparation example 1

[0067] Preparation Example 1: Preparation of delimed semi-coke

[0068] Crush 2000g of semi-coke into particles with an average particle size of 2-5mm, and dry at 130°C for 3h.

[0069] Then take 1000g of dried semi-coke and soak it in 1500mL of 2mol / L hydrochloric acid solution, keep the temperature at 75°C for 12h, then wash it with water until neutral, then soak it in 1500mL of 2mol / L hydrofluoric acid solution at 75°C for 12h , washed with water until neutral, and then dried at 110°C for 10 hours to obtain delimed semi-coke. Cool to room temperature and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com