Vacuum circuit breaker force reducing device

A technology of vacuum circuit breaker and vacuum tube, applied in high-voltage air circuit breaker, circuit, high-voltage/high-current switch, etc., can solve the problems of overall complexity, reduced service life, and cumbersome replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

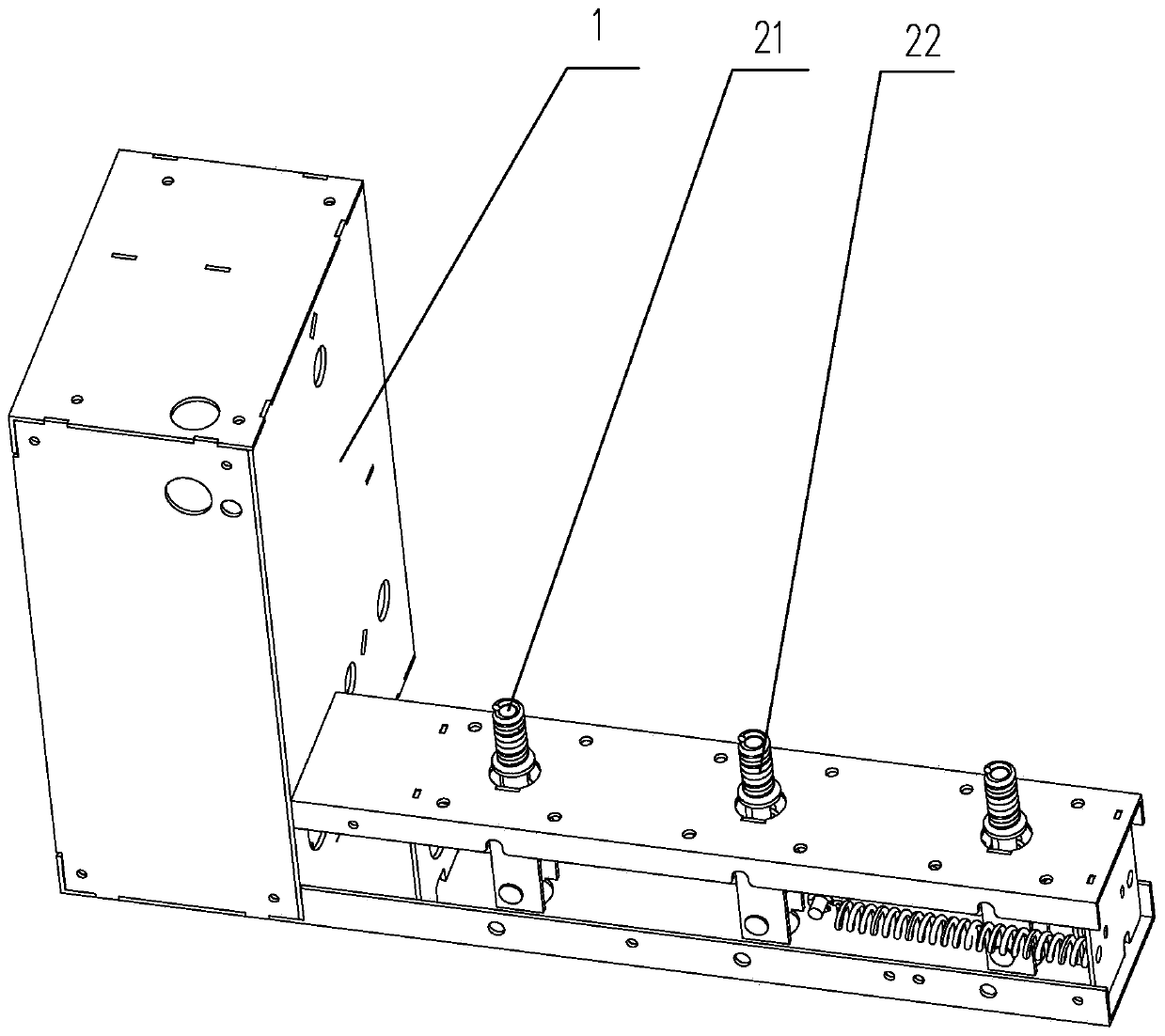

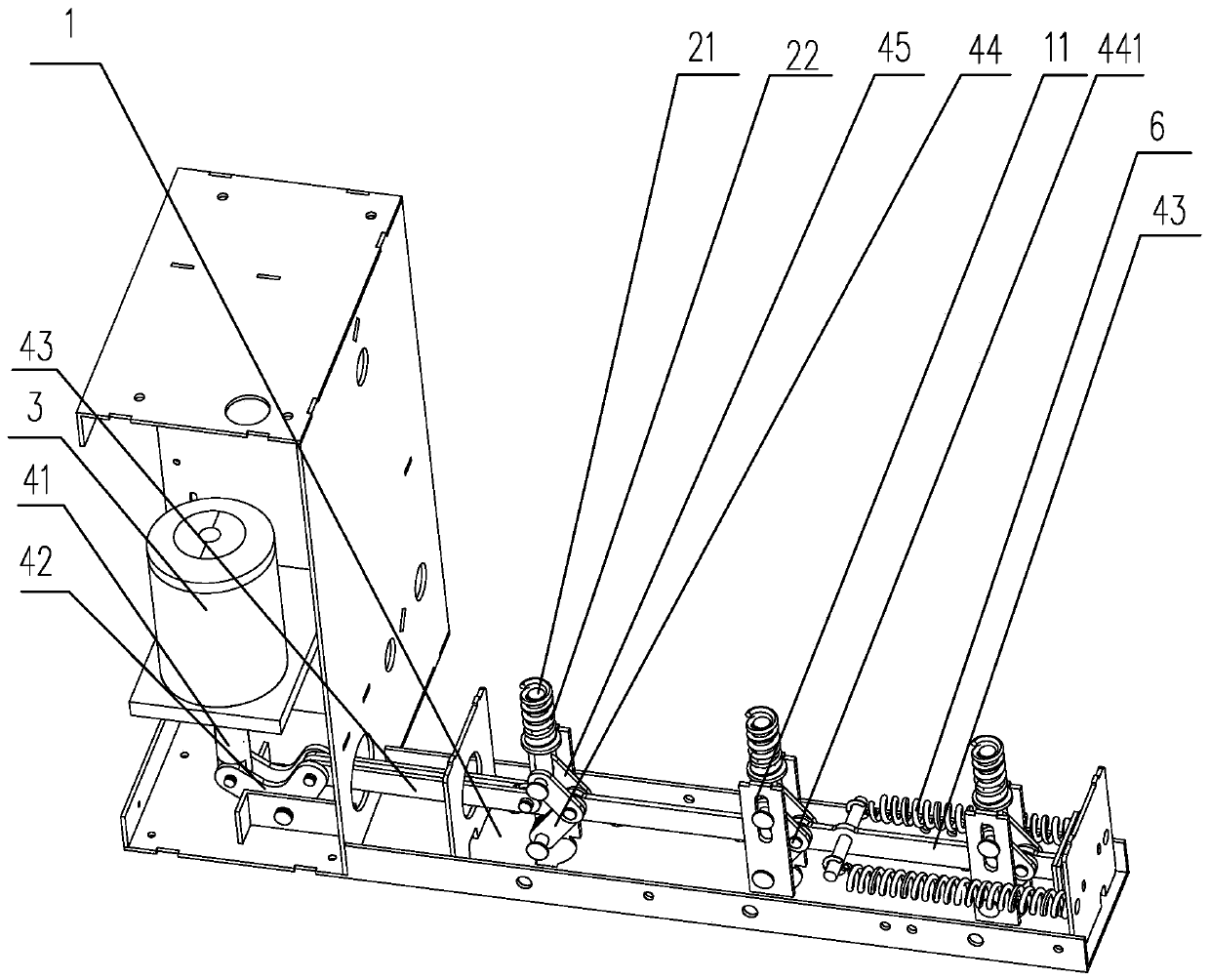

[0018] Example one: by figure 1 , figure 2 It can be seen that the present invention discloses an embodiment of a vacuum circuit breaker force reducing device, which includes a bracket 1, a plurality of vacuum tubes, and a driving mechanism for driving the vacuum tubes to open and close, and the vacuum tubes are arranged on the bracket 1 at intervals, The vacuum tube is respectively provided with a connecting rod 21 for opening and closing the vacuum tube, the connecting rod 21 is sleeved with a reset extension spring 22 for resetting the connecting rod 21 to the opening position of the vacuum tube, and the driving mechanism includes a drive Part 3, a crank arm 42 and a transmission rod 41, the driving part 3 is in transmission connection with the transmission rod 41, the crank arm 42 is hingedly arranged on the support 1 and is in transmission connection with the transmission rod 41, and the crank arm 42 is also connected There is a main shaft 43 used to drive the vacuum tube ...

Embodiment 2

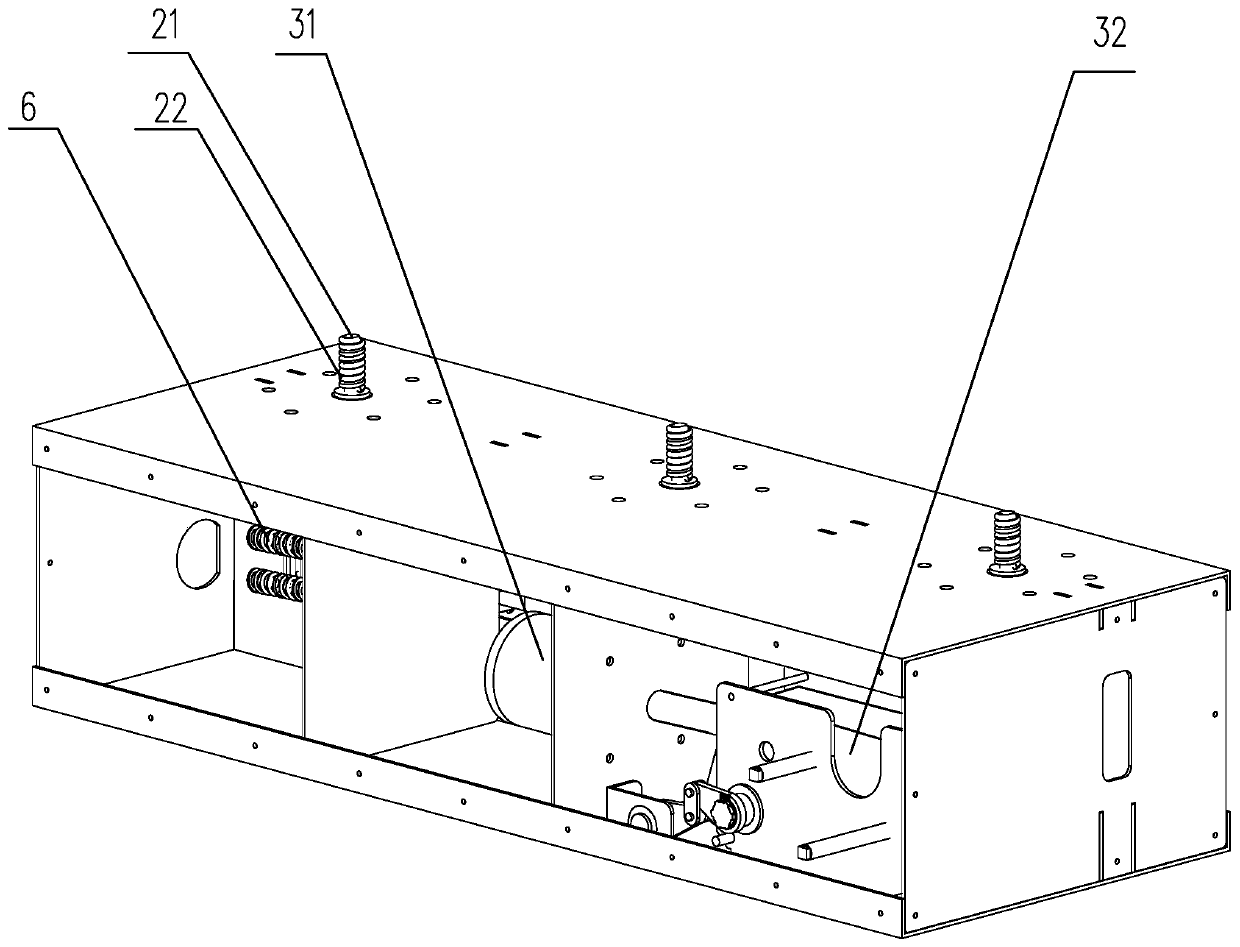

[0019] Example two: by image 3 , Figure 4 It can be seen that the present invention discloses another embodiment of a vacuum circuit breaker force reducing device, which includes a bracket 1, a plurality of vacuum tubes, and a driving mechanism for driving the vacuum tube to open and close. The vacuum tubes are arranged on the bracket 1 at intervals , The vacuum tube is respectively provided with a connecting rod 21 for opening and closing the vacuum tube, the connecting rod 21 is sleeved with a reset tension spring 22 for resetting the connecting rod 21 to the opening position of the vacuum tube, and the driving mechanism includes The driving part 3, the turning arm 42, the transmission rod 41 and the transmission group for driving the turning arm 42 to rotate, the driving part 3 includes a permanent magnet operation box 31 and a mechanical operation box 32, and the driving rod includes a first driving rod 52 And the second driving rod 53, the permanent magnet operating box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com