Method for preparing dihydrostreptomycin sulfate based on microreactor

A technology of dihydrostreptomycin sulfate and streptomycin sulfate, which is applied in the field of preparation of dihydrostreptomycin sulfate based on microreactors, can solve the problems of high reducing agent consumption, low production efficiency, and potential safety hazards, and it is easier to achieve ash content Qualification, burden reduction, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

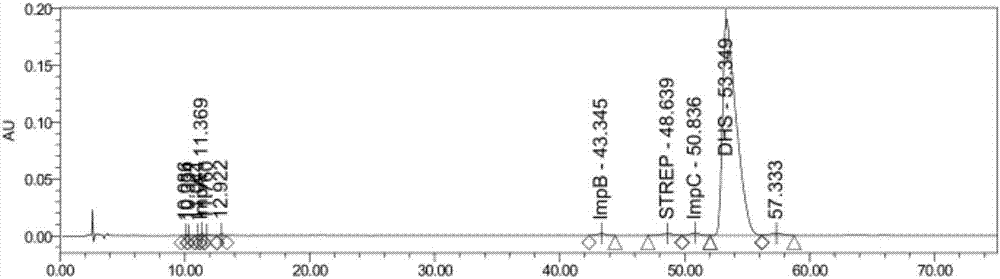

[0024] The titer of streptomycin sulfate circulating analysis solution is 174059U / mL, adjust the pH to 6.5 with sodium hydroxide, and enter the microreactor from different flow channels with potassium borohydride solution, and place the microreactor in a water bath at 18°C. Reaction, residence time 10s. The micro-reactor micro-channel section depth of embodiment 1.1 to 1.6 is 0.5 mm, and the width ranges from 1-10 mm. The flow rate of the circulating analytical solution is 10mL / min, and the potassium borohydride solution is controlled to enter the microreactor in different amounts. Table 1.1 is the conversion rate when the different potassium borohydride additions of embodiment 1.1 to 1.6, figure 1 It is embodiment 1.6 product collection of illustrative plates, table 1.2 is peak result chart.

[0025] Table 1.1

[0026]

[0027] Table 1.2

[0028] peak result

[0029]

Embodiment 2

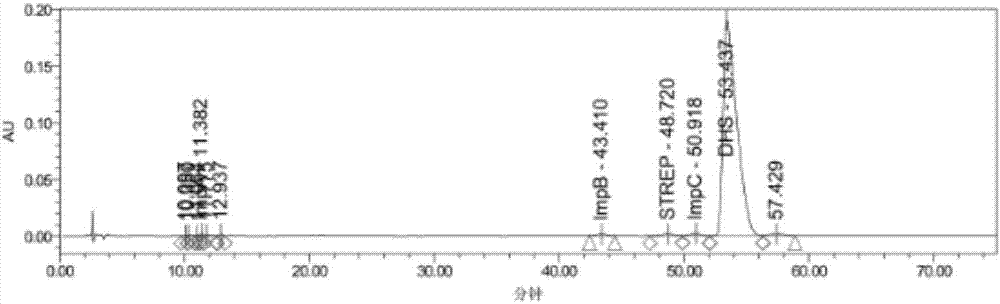

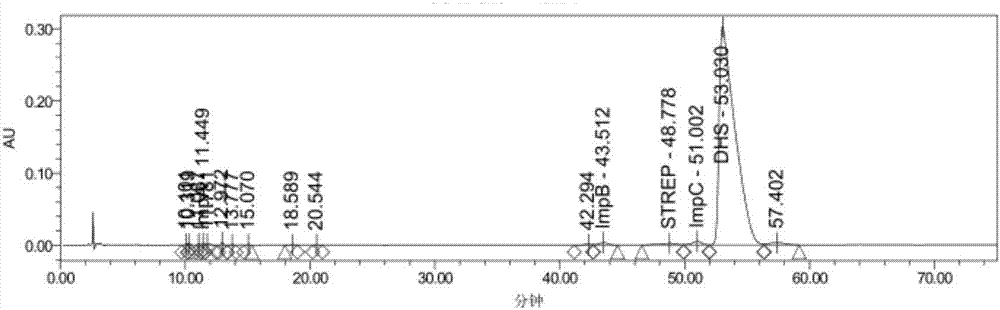

[0032] The titer of streptomycin sulfate circulating analysis solution is 96799U / mL, adjust the pH to 6.75 with sodium hydroxide, enter the microreactor from different flow channels with potassium borohydride solution, and place the microreactor in a water bath at 20°C. Reaction, residence time 10s. The microreactor microchannel section depth of embodiment 2.1 to 2.2 is 0.5mm, and width 1-10mm does not wait. The flow rate of the circulating analytical solution is 10mL / min, and the potassium borohydride solution is controlled to enter the microreactor in different amounts. Table 2.1 is the conversion rate when different potassium borohydride additions are made in Examples 2.1 to 2.2, figure 2 For embodiment 2.2 product collection of illustrative plates, table 2.2 is peak result graph, image 3 It is the product spectrum of Example 2.3, and Table 2.5 is the peak result chart.

[0033] Table 2.1

[0034]

[0035] Table 2.2

[0036] peak result

[0037]

[0038] Table...

Embodiment 3

[0043] The titer of the streptomycin sulfate circulating analysis solution is 13333U / mL, the pH is adjusted to 6.8 with sodium hydroxide, and the potassium borohydride solution enters the microreactor from different flow channels, and the microreactor is placed in a water bath at 17°C. Reaction, residence time 10s. The microreactor microchannel section depth of embodiment 3.1 to 3.2 is 0.5mm, and width 1-10mm does not wait. The flow rate of the circulating analytical solution is 20mL / min, and the potassium borohydride solution is controlled to enter the microreactor in different amounts. Table 3 is the conversion rate when different potassium borohydride additions are made in Examples 3.1 to 3.2.

[0044] table 3

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com