Shutter vehicle shutter-turning mechanism and lifting transmission system comprising same

The technology of lifting transmission and louver car is applied in the field of radial tire manufacturing, which can solve the problems of easy deformation or damage of the tread, high labor intensity of workers, and unfavorable tire quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

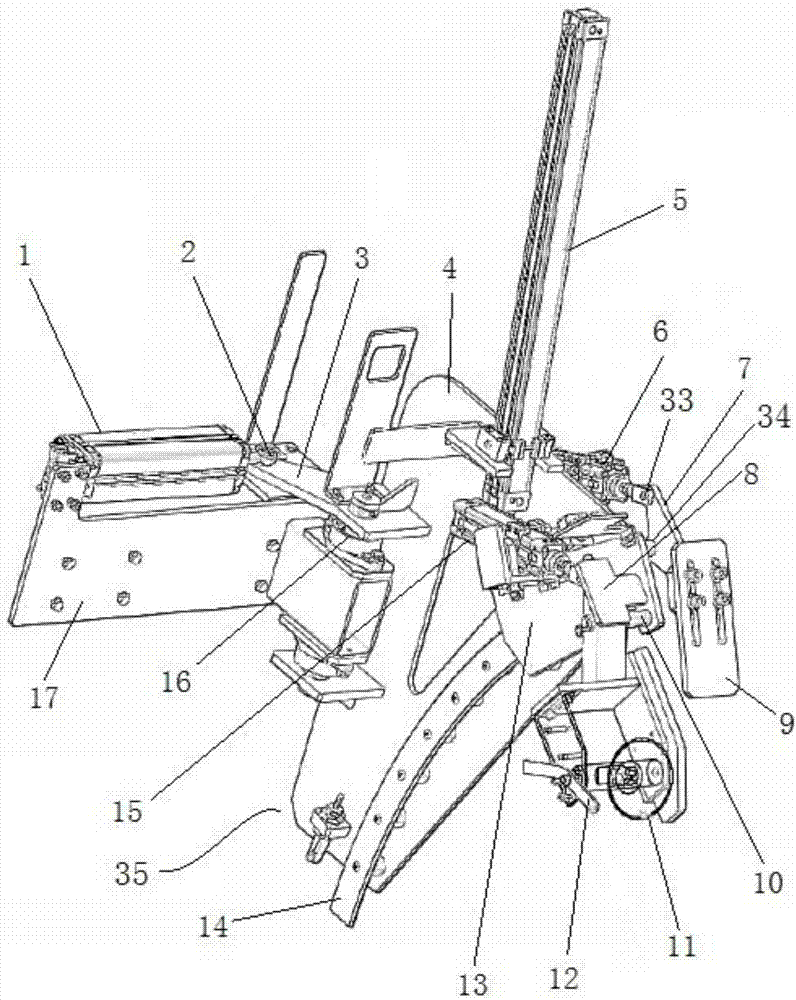

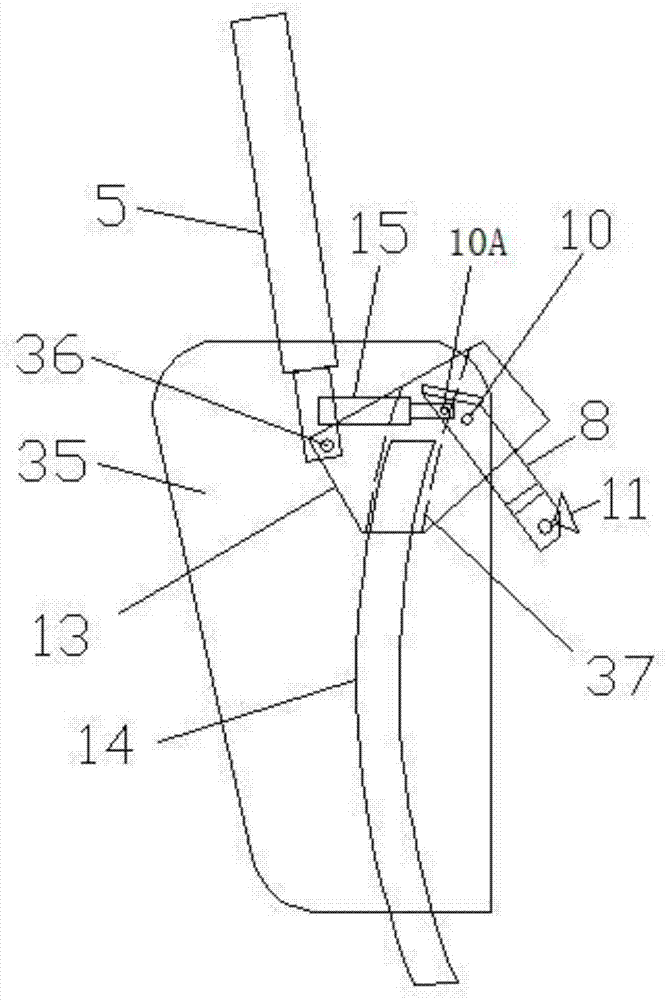

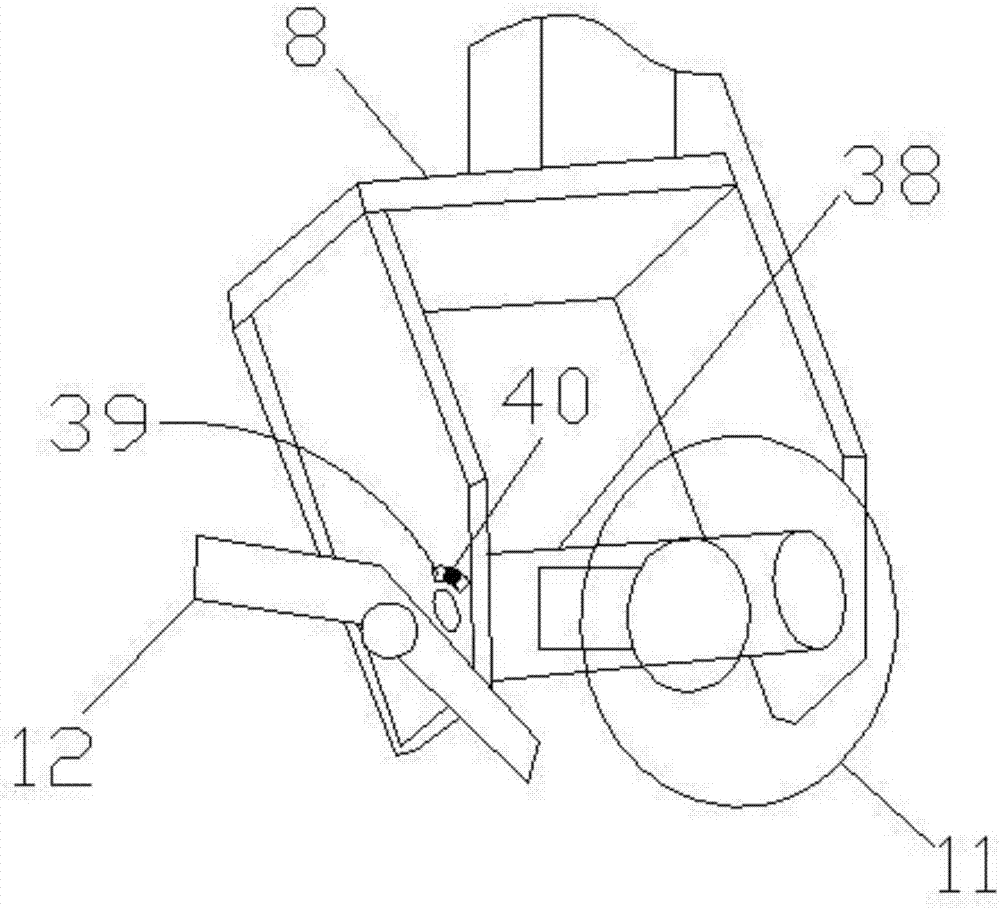

[0022] Depend on Figure 1-Figure 3 The page-turning mechanism of the shutter car shown includes a fixed seat 17 for driving the cylinder 1 of the rotary frame, a rotary frame 35 hinged to the fixed seat 17 through the hinge axis A16, a lifting cylinder 5 vertically arranged on the rotary frame 35, and a lifting cylinder 5 arranged vertically on the rotary frame. Cylinder 5 drives the sucker seat 13 of lifting, the sucker driving cylinder 15 that is arranged on the sucker seat 13, the sucker connecting frame 8 that is hinged with the sucking cup seat 13 by hinge shaft B10, the sucking cup 11 that is provided with on the sucking cup connecting frame 8 and a supporting mechanism.

[0023] The rotary frame drive cylinder 1 is horizontally arranged on the left and right sides, the left end of the cylinder body of the rotary frame drive cylinder 1 is fixed or hinged on the fixed seat 17, the telescopic rod of the rotary frame drive cylinder 1 extends horizontally to the right and ca...

Embodiment 2

[0035] Depend on Figure 4-Figure 7 The lifting transmission system shown includes a main frame 28 provided with a lifting platform, a lifting device that drives the lifting platform up and down, and two shutter vehicle page-turning mechanisms 32 described in Embodiment 1, the fixed seat 17 of the shutter vehicle page-turning mechanism 32 and Lifting platform is fixedly connected, and two louver car page-turning mechanisms 32 are arranged at intervals.

[0036] The main frame 28 is a cube-shaped frame structure. Described elevating platform comprises upper beam 24 and the rectangular frame 26 that horizontally arranges, and upper beam 24 is fixedly connected with rectangular frame 26, and rectangular frame 26 comprises front beam 25, rear beam 27, left connecting plate 42 and right connecting plate 43, and front beam 25 and rear crossbeam 27 all are left and right horizontal extensions, and left connecting plate and right connecting plate all are front and rear horizontal ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com