Method for improving smoothness of weld joint of metal vacuum cup and automatic welding equipment for method

A thermos cup and smoothness technology, which is applied in the direction of laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of unsatisfactory weld smoothness, jagged appearance, and difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

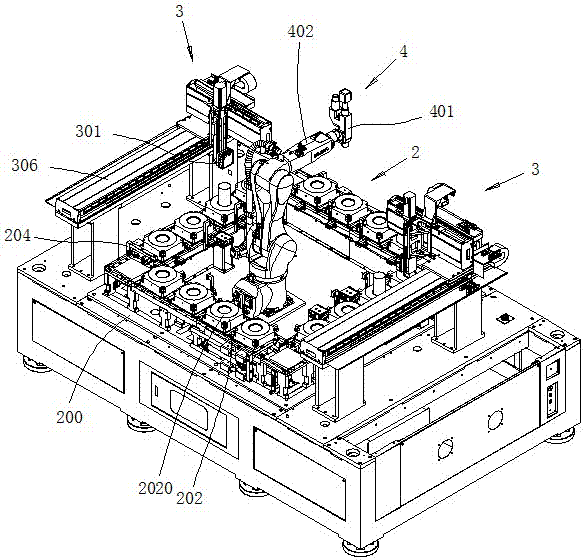

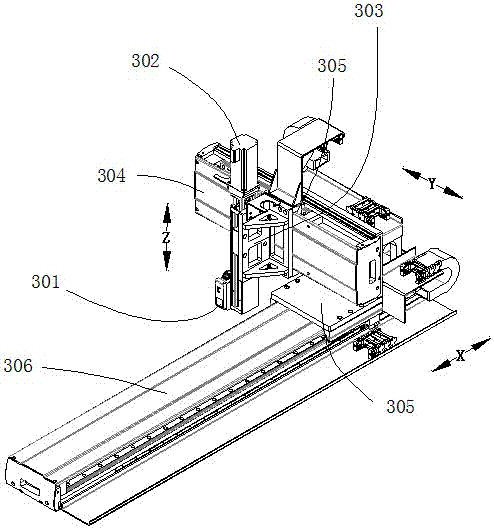

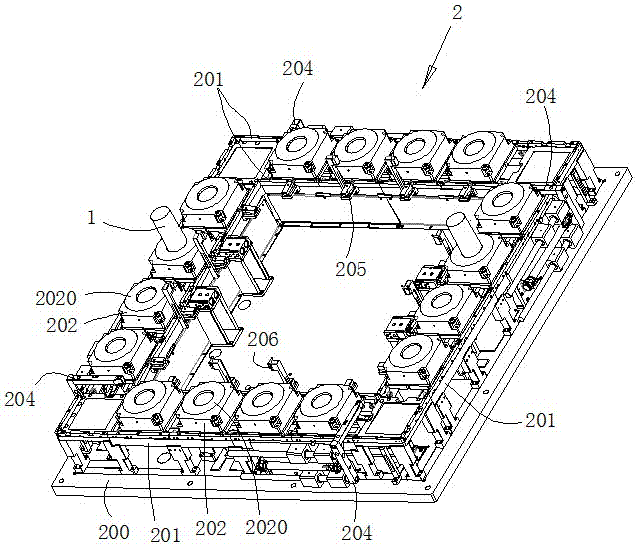

[0056] In order to make the technical solution of the present invention clearer, the following in conjunction with the attached Figures 1 to 7 , the present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention, and are not intended to limit the protection scope of the present invention.

[0057] The invention is a method for improving the smoothness of the welding seam of a metal thermos cup, comprising the following steps:

[0058] Step 1: Weld data collection

[0059] Utilize the 3D camera 301 to scan the port gap of the metal insulation cup 1 to be welded below it, and then transmit the scanned weld seam data to the control device;

[0060] Step 2: Screen weld data

[0061] The control device compares the weld seam data collected by the 3D camera 301 with the theoretical circular curve of the port of the metal thermos cup, and if the spatial distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com