Radiation inspection system

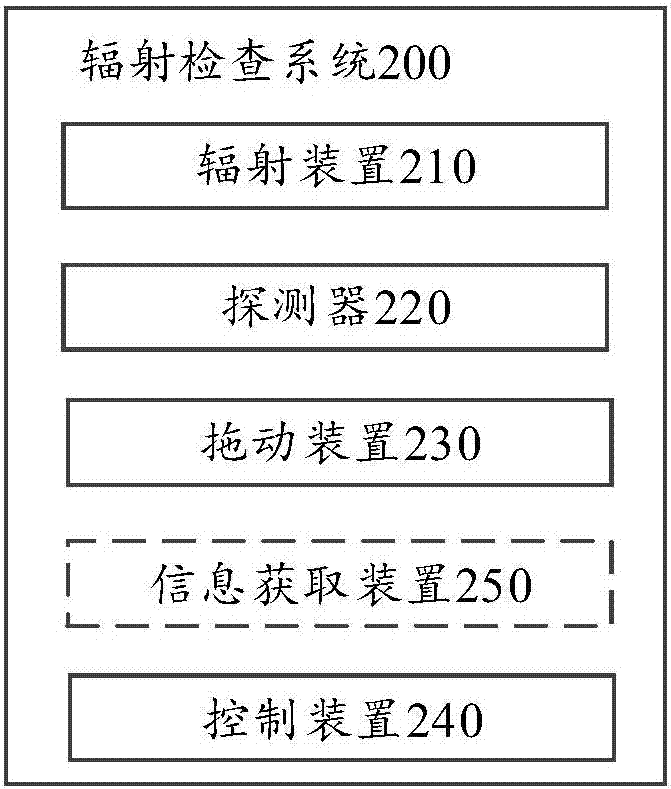

A technology of inspection system and radiation device, applied in the field of radiation inspection, to achieve the effect of improving quality and reducing height and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

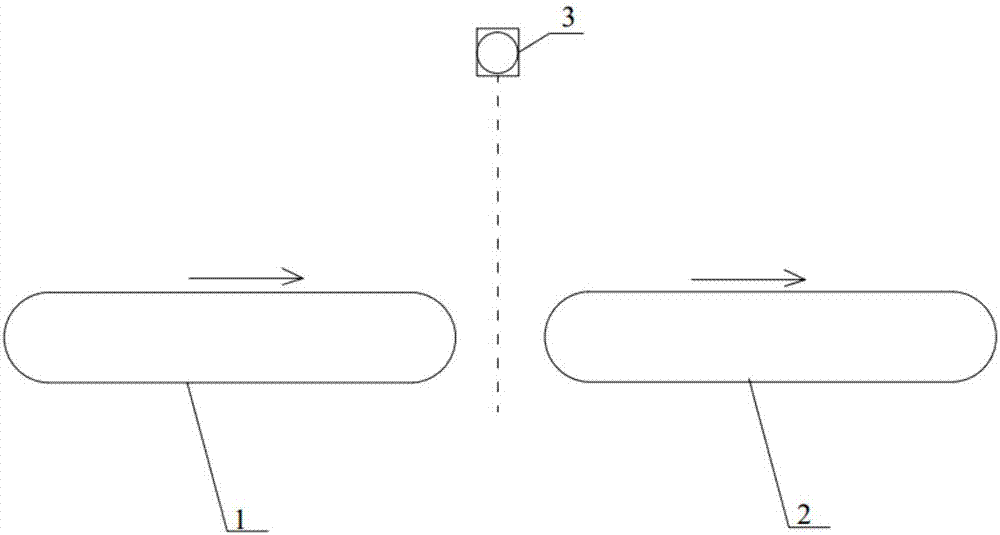

[0132] see Figure 10-Figure 13 ,in Figure 10 It is a front view showing that the radiation inspection system built by the present invention drags and scans the vehicle; Figure 10A yes Figure 10 The enlarged schematic diagram of the part of the dragging device in ; Figure 11 It is a front view showing the drive-through scanning of the vehicle by the radiation inspection system built by the present invention; Figure 11A yes Figure 11 The enlarged schematic diagram of the part of dragging device in ; Figure 12 is a side view; Figure 13 is a top view.

[0133] The rack 100 can be built on the chassis 1001 . The frame 100 can include a left column frame and a right column frame, perpendicular to the chassis 1001 upper surface. The lower ends of the left column frame and the right column frame are respectively connected with the left and right sides of the chassis 1001, and the upper ends are respectively connected with the left and right sides of the beam frame. Th...

Embodiment 2

[0180] see Figure 14-Figure 17 ,in Figure 14 It is a front view showing that the radiation inspection system built by the present invention drags and scans the vehicle; Figure 15 It is a front view showing the drive-through scanning of the vehicle by the radiation inspection system built by the present invention; Figure 16 is a side view; Figure 17 is a top view.

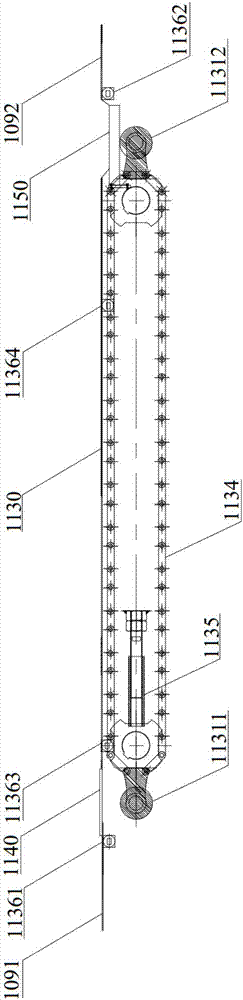

[0181] Different from Embodiment 1, the radiation inspection system in this embodiment adopts bilateral dragging devices, that is, a dragging device is provided on both sides of the radiation inspection channel. Moreover, the dragging device is a chain plate / flat dragging device. Only the differences are described below, and for the same parts, please refer to the related description above.

[0182] As shown in the figure, the first dragging device 213 and the second dragging device 214 are both single-stage flat plate / chain plate conveyor structures, installed on both sides of the radiation inspection ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com