Dustproof device for building construction socket

A dust-proof device and construction technology, which is applied in the direction of coupling device, two-part connection device, electrical components, etc., can solve the problems of low safety, shorten the life of the socket, affect the socket, etc., achieve convenient sockets, increase the service life, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

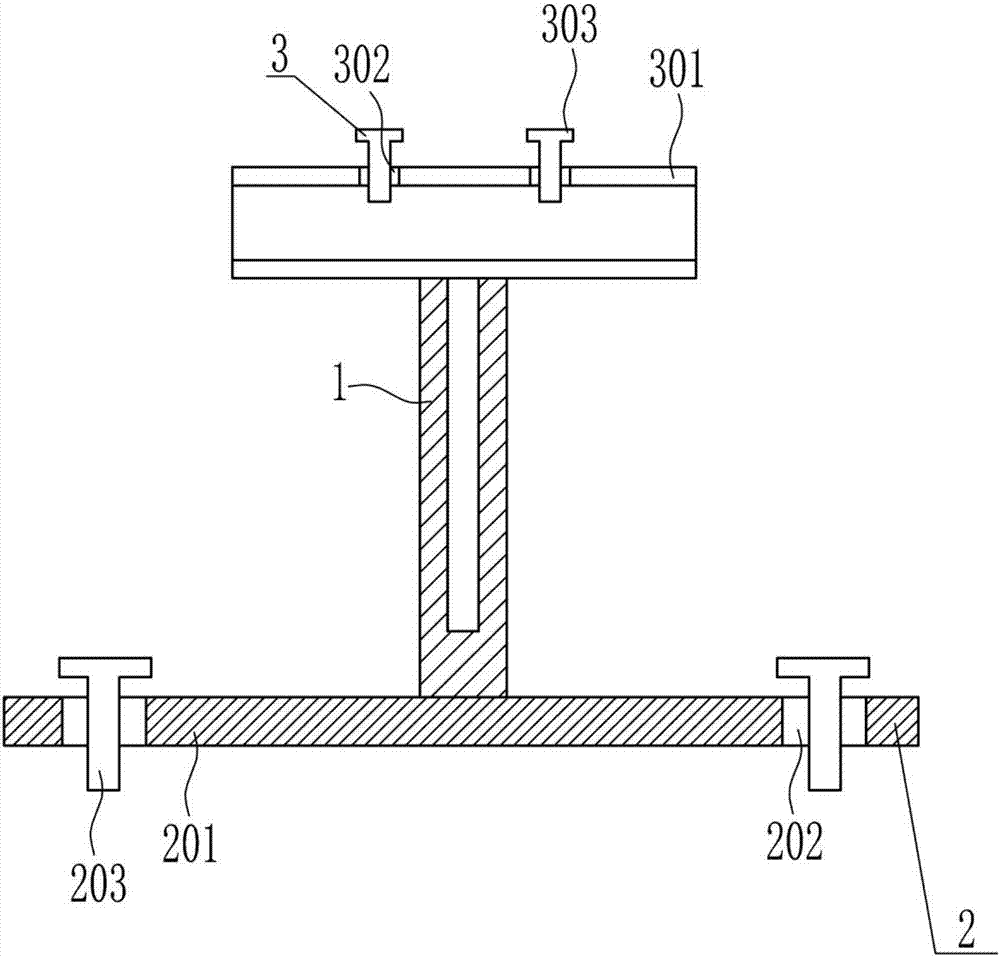

[0036] A dust-proof device for building construction sockets, such as Figure 1-6 As shown, it includes a hollow sleeve 1 , a fixing mechanism 2 and a placement mechanism 3 , the bottom end of the hollow sleeve 1 is connected with the fixing mechanism 2 , and the top end of the hollow sleeve 1 is connected with the placement mechanism 3 .

Embodiment 2

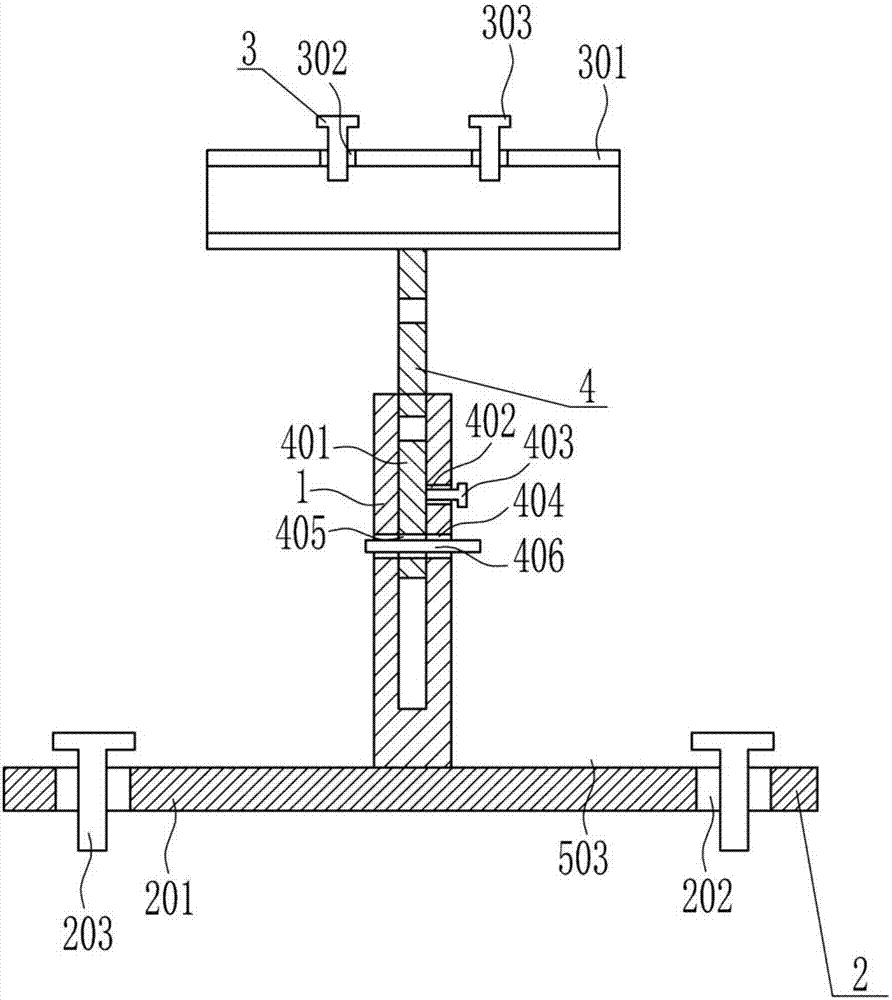

[0038] A dust-proof device for building construction sockets, such as Figure 1-6 As shown, it includes a hollow sleeve 1 , a fixing mechanism 2 and a placement mechanism 3 , the bottom end of the hollow sleeve 1 is connected with the fixing mechanism 2 , and the top end of the hollow sleeve 1 is connected with the placement mechanism 3 .

[0039] The fixing mechanism 2 includes a base plate 201 and a first screw rod 203. The bottom end of the hollow sleeve 1 is connected to the base plate 201. Two first screw holes 202 are symmetrically opened on the left and right sides of the base plate 201. The first screw holes 202 are equipped with Two first screws 203 .

Embodiment 3

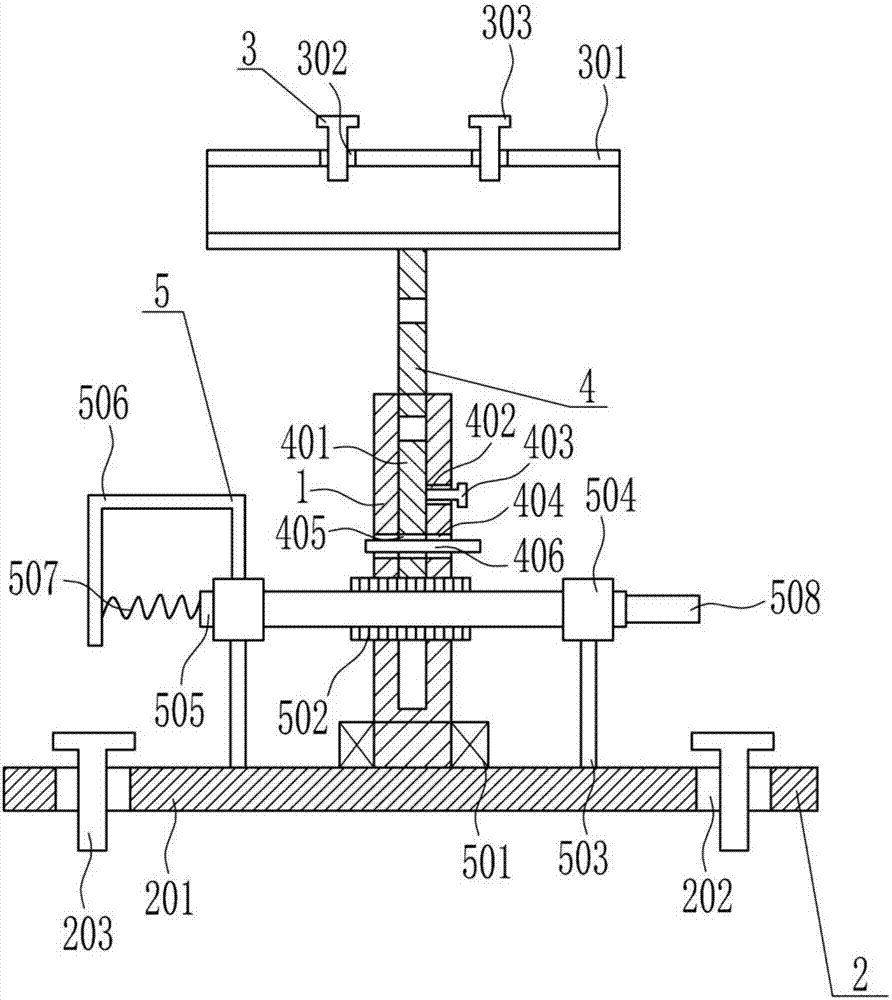

[0041] A dust-proof device for building construction sockets, such as Figure 1-6As shown, it includes a hollow sleeve 1 , a fixing mechanism 2 and a placement mechanism 3 , the bottom end of the hollow sleeve 1 is connected with the fixing mechanism 2 , and the top end of the hollow sleeve 1 is connected with the placement mechanism 3 .

[0042] The fixing mechanism 2 includes a base plate 201 and a first screw rod 203. The bottom end of the hollow sleeve 1 is connected to the base plate 201. Two first screw holes 202 are symmetrically opened on the left and right sides of the base plate 201. The first screw holes 202 are equipped with Two first screws 203 .

[0043] The placement mechanism 3 includes a placement plate 301 and a second screw rod 303, the top of the hollow sleeve 1 is connected with the placement plate 301, and the left and right sides of the inner top of the placement plate 301 are symmetrically provided with second screw holes 302. There is a second screw 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com