An automatic ammonia addition system and method applied to an ammonia desulfurization device

A kind of ammonia desulfurization, automatic technology, applied in chemical instruments and methods, separation methods, control/regulation systems, etc., can solve problems such as ammonia escape and aerosol formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

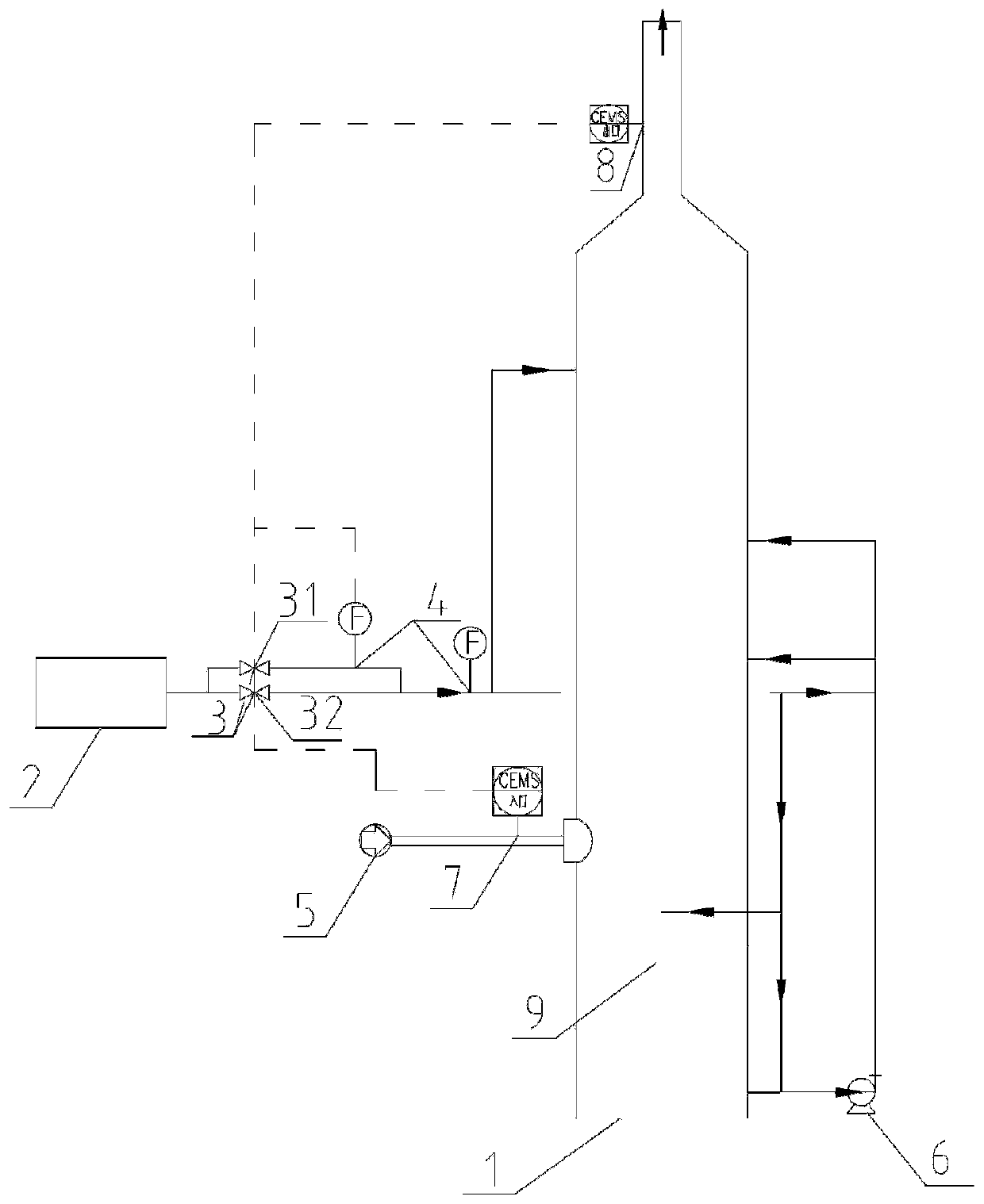

[0117] use figure 1 The shown ammonia desulfurization device including the automatic ammonia addition system of the present invention treats raw flue gas, wherein 1 indicates the absorption tower, 2 indicates the ammonia supply system, 3 indicates the ammonia addition regulating valve, and 4 indicates the quality of the ammonia addition metering means Flow meter, 5 indicates the original flue gas, 6 indicates the circulation pump, 7 indicates the inlet CEMS, 8 indicates the outlet CEMS, and 9 indicates the oxidation section. Original flue gas volume 360000-510000Nm 3 / h,SO 2 Concentration 1000-30000mg / Nm 3 , total dust concentration 15-30mg / Nm 3 .

[0118] The ammonia absorbent supplied by the ammonia supply system 2 is liquid ammonia.

[0119] Double control valves are used to control automatic ammonia addition. The inlet of the ammonia addition control valve 3 is connected to the ammonia supply system 2, and the outlet is connected to the ammonia addition points such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com