Extruding flat plate mop cleaning tool capable of being set upright

A flat mop and cleaning tool technology, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of poor operability and laborious operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

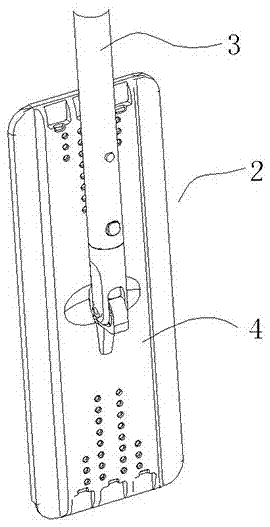

[0092] refer to Figure 1~Figure 8 , a flat mop cleaning tool that can be erected, comprising a mop bucket 1 and a flat mop 2, the flat mop 2 comprising a mop rod 3 and a flat mop head 4 movably connected to the mop rod 3, the flat mop Head 4 is provided with wiping thing, and wiping thing can be located at the front or back side of flat mop head 4 or front and back side all is provided with wiping thing.

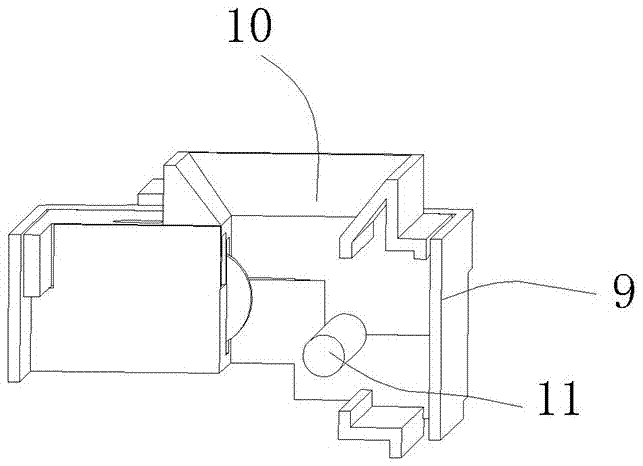

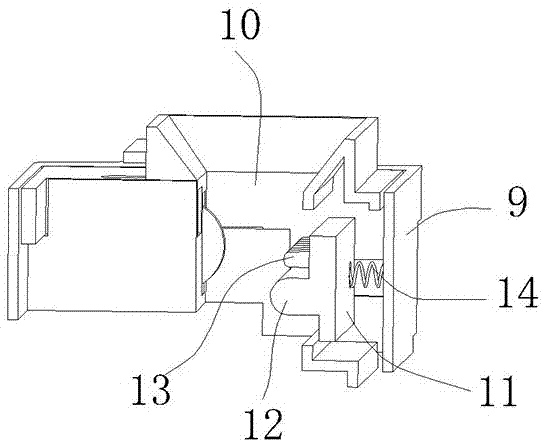

[0093] The mop bucket 1 has an independent squeezing area 5 and an independent cleaning area 6 . The mop bucket 1 is equipped with a mouth-stretching extrusion device 7, and when cleaning and squeezing the water, the flat mop head 4 is rotated to a state where it can be cleaned and squeezed. The usual form of this state is: a flat mop The head 4 is rotated to be parallel to the mop rod 3 (of course, it can also be rotated to a no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com