Method for preparing alkaline type magnesium iodide crystal whiskers

A magnesium iodide and whisker technology, applied in the field of inorganic material preparation, can solve the problems of resource waste, bittern utilization rate less than 20%, and affecting the ecological balance of offshore waters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing basic magnesium iodide whiskers, comprising the steps of:

[0025] S1. Take 300mL of bittern (bitter is taken from Xuwen Salt Field, Guangdong), filter and discard the insoluble matter;

[0026] S2. prepare the NaOH solution of 0.8mol / L and the NaI solution of 3mol / L;

[0027] S3. Mix the NaI solution and the bittern solution in a volume ratio of 3:1 to obtain a mixed solution 1;

[0028] S4. Take 150mL of mixed solution 1, put it in a 250mL Erlenmeyer flask, place the Erlenmeyer flask in a 30°C water bath to 30°C, then slowly add 50mL of 0.8mol / L NaOH solution dropwise under stirring, to obtain Mixture 2;

[0029] S5. Put the mixed solution 2 in a water bath with a water temperature of 35°C to continue aging for 55 hours, filter and collect the precipitate, and dry it in an oven (T=80±3°C, t=24h) to obtain basic iodine Magnesium whiskers.

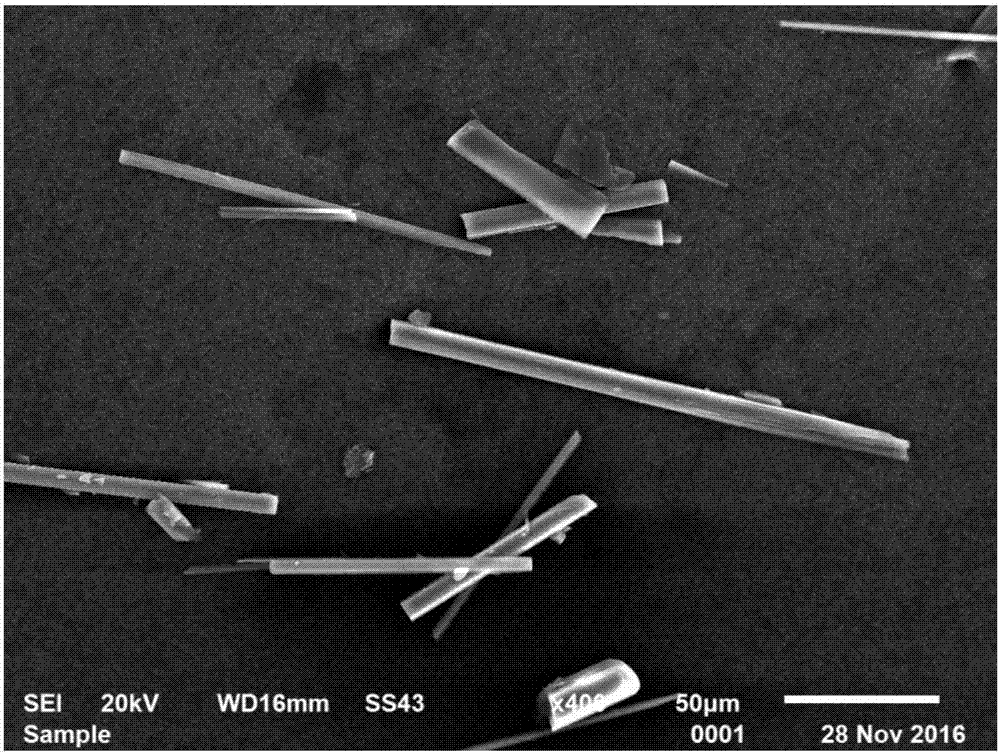

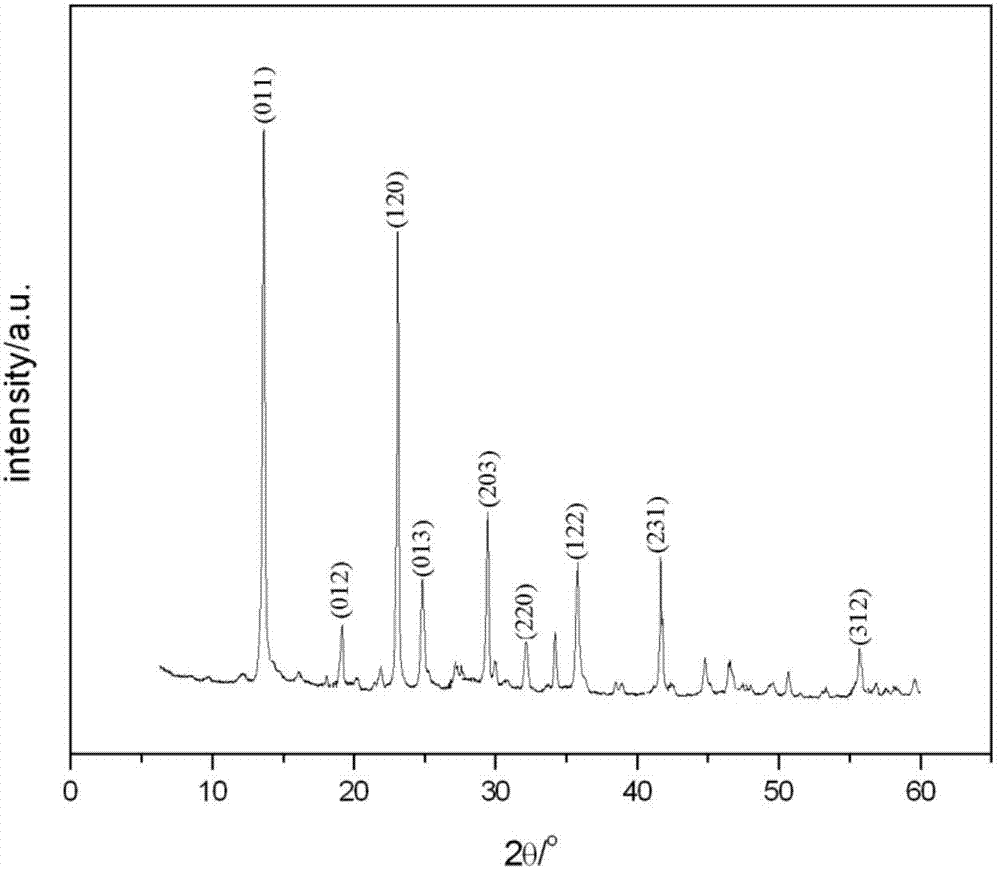

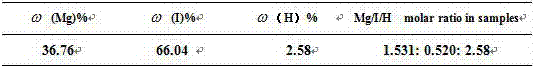

[0030] Measure the XRD, SEM, elemental analysis result of gained whisker, SEM test shows to be whisker ...

Embodiment 2

[0034] A method for preparing basic magnesium iodide whiskers, comprising the steps of:

[0035] S1. Take 300mL of bittern (bitter is taken from Xuwen Salt Field, Guangdong), filter and discard the insoluble matter;

[0036] S2. prepare the NaOH solution of 0.8mol / L and the NaI solution of 3mol / L;

[0037] S3. Mix the NaI solution and the bittern solution in a volume ratio of 3:1 to obtain a mixed solution 1;

[0038] S4. Take 100mL of mixed solution 1, put it in a 250mL Erlenmeyer flask, place the Erlenmeyer flask in a 30°C water bath to 30°C, and then slowly add 33mL of 0.8mol / L NaOH solution dropwise under stirring to obtain Mixture 2;

[0039] S5. Put the mixed solution 2 in a water bath with a water temperature of 35°C to continue aging for 55 hours, filter and collect the precipitate, and dry it in an oven (T=80±3°C, t=24h) to obtain basic iodine Magnesium oxide whiskers, the yield of whiskers is 91%, and the aspect ratio of whiskers is 16:1.

Embodiment 3

[0041] A method for preparing basic magnesium iodide whiskers, comprising the steps of:

[0042] S1. Take 300mL of bittern (bitter is taken from Xuwen Salt Field, Guangdong), filter and discard the insoluble matter;

[0043] S2. prepare the NaOH solution of 0.8mol / L and the NaI solution of 3mol / L;

[0044] S3. Mix the NaI solution and the bittern solution in a volume ratio of 3:1 to obtain a mixed solution 1;

[0045] S4. Take 50mL of mixed solution 1 and place it in a 250mL Erlenmeyer flask, place the Erlenmeyer flask in a 30°C water bath to 30°C, then slowly add 17mL of 0.8mol / L NaOH solution dropwise under stirring to obtain a mixture Liquid 2;

[0046] S5. Put the mixed solution 2 in a water bath with a water temperature of 35°C to continue aging for 55 hours, filter and collect the precipitate, and dry it in an oven (T=80±3°C, t=24h) to obtain basic iodine Magnesium oxide whiskers, the yield of whiskers is 90%, and the aspect ratio of whiskers is 15:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com