Stacked-blade rapid distributing, conveying and locating device and distributing, conveying and locating method thereof

A positioning device and blade technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of conveying efficiency and positioning effect, worker's blade injury, slow material distribution speed, etc., to achieve good positioning effect and high material distribution speed Fast, high efficiency in material distribution and conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

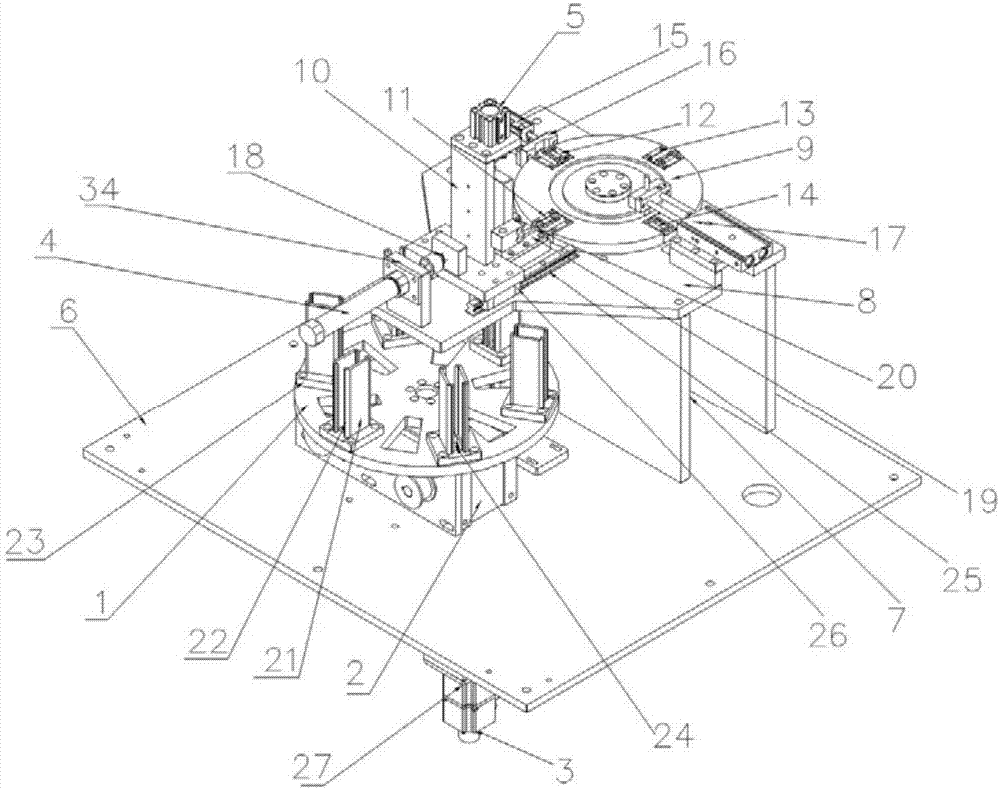

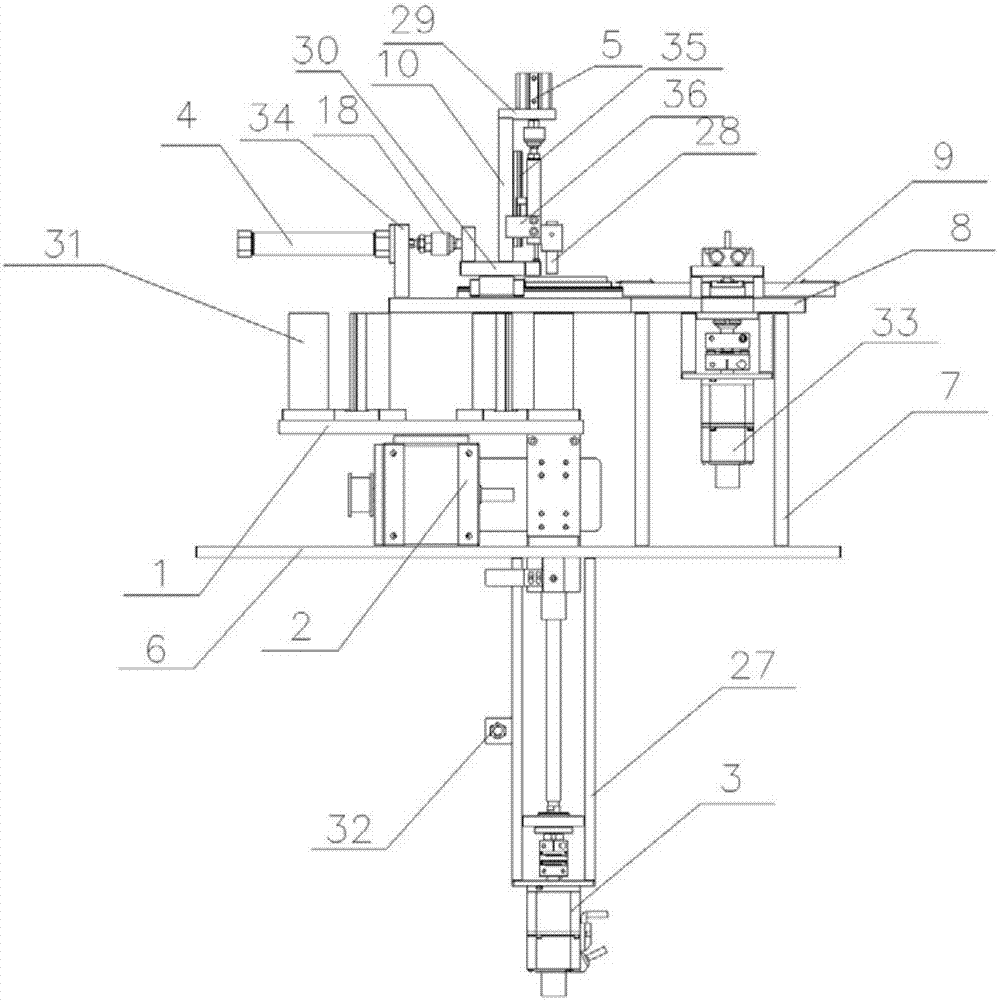

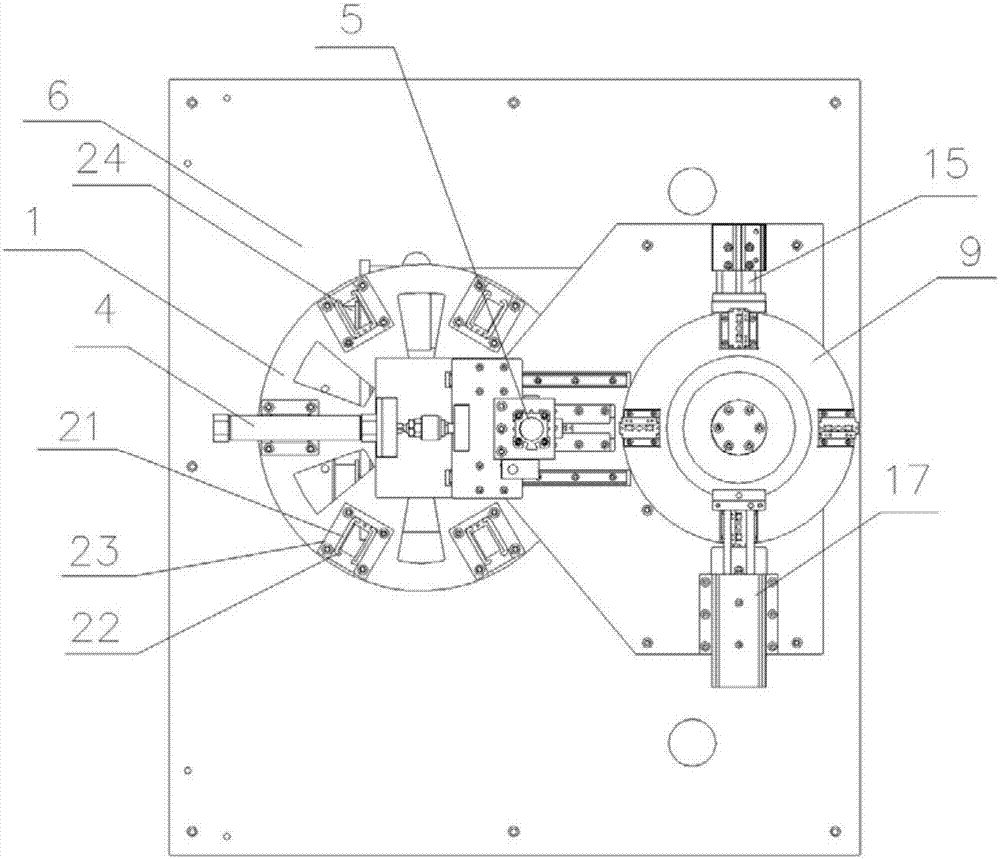

[0038] like Figure 1-3As shown, a stacking blade rapid material distribution and conveying positioning device includes a support plate 6, an electric control box, a material distribution mechanism and a conveying positioning mechanism installed on the support plate 6. The material distribution mechanism includes a feeding indexing plate 1, a feeding indexing plate drive motor 2, a number of storage bins 31 installed on the feeding indexing plate 1, and a jack for pushing up the blades in the storage bin 31. The lifting mechanism and the feeding cylinder 4 for quickly distributing the positioned blades. The upward stroke of the jacking mechanism matches the thickness of a single blade. The conveying positioning mechanism includes a positioning cylinder 5, a positioning head 28, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com