Industrial fire fighting robot with lift stage

A fire-fighting robot and stage technology, applied in lifts, manipulators, lifting devices, etc., can solve the problems of fire personnel injury, slow speed, sacrifice of life, etc., to avoid bending over to take it, improve fire-fighting efficiency, and reduce labor the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

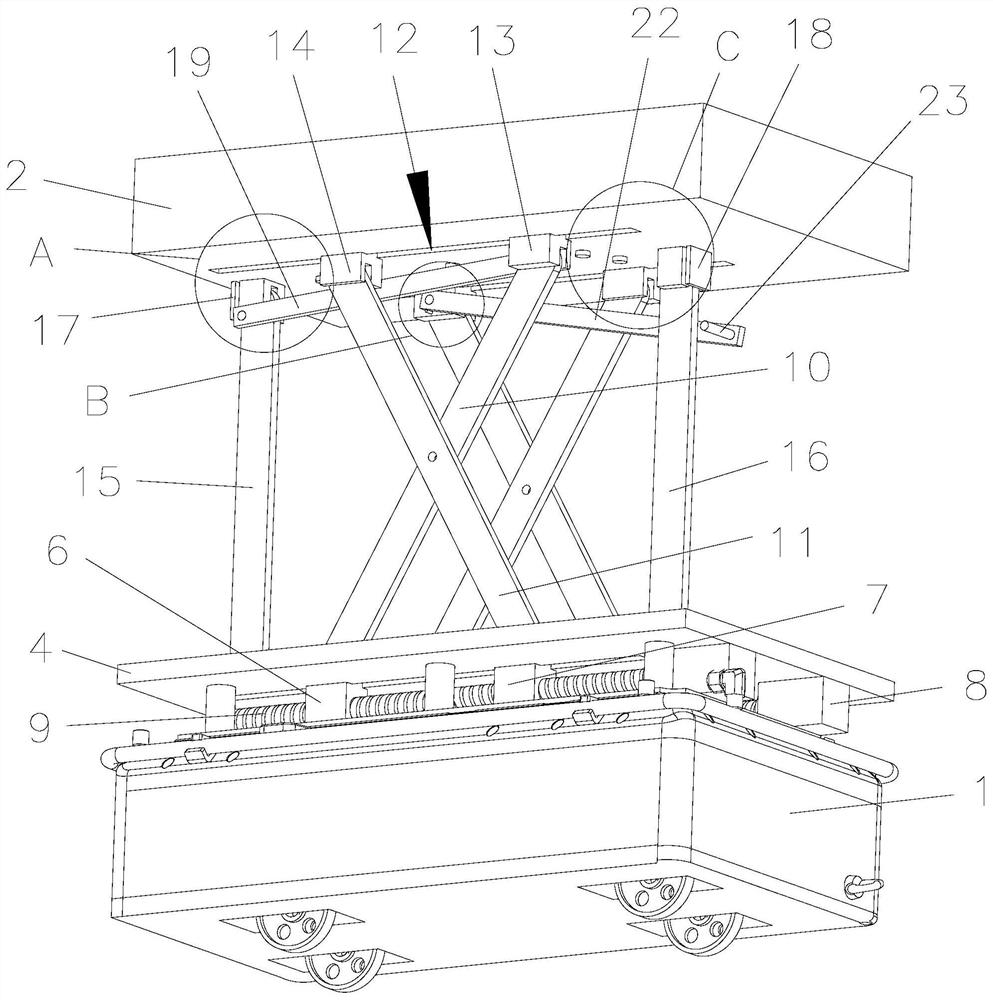

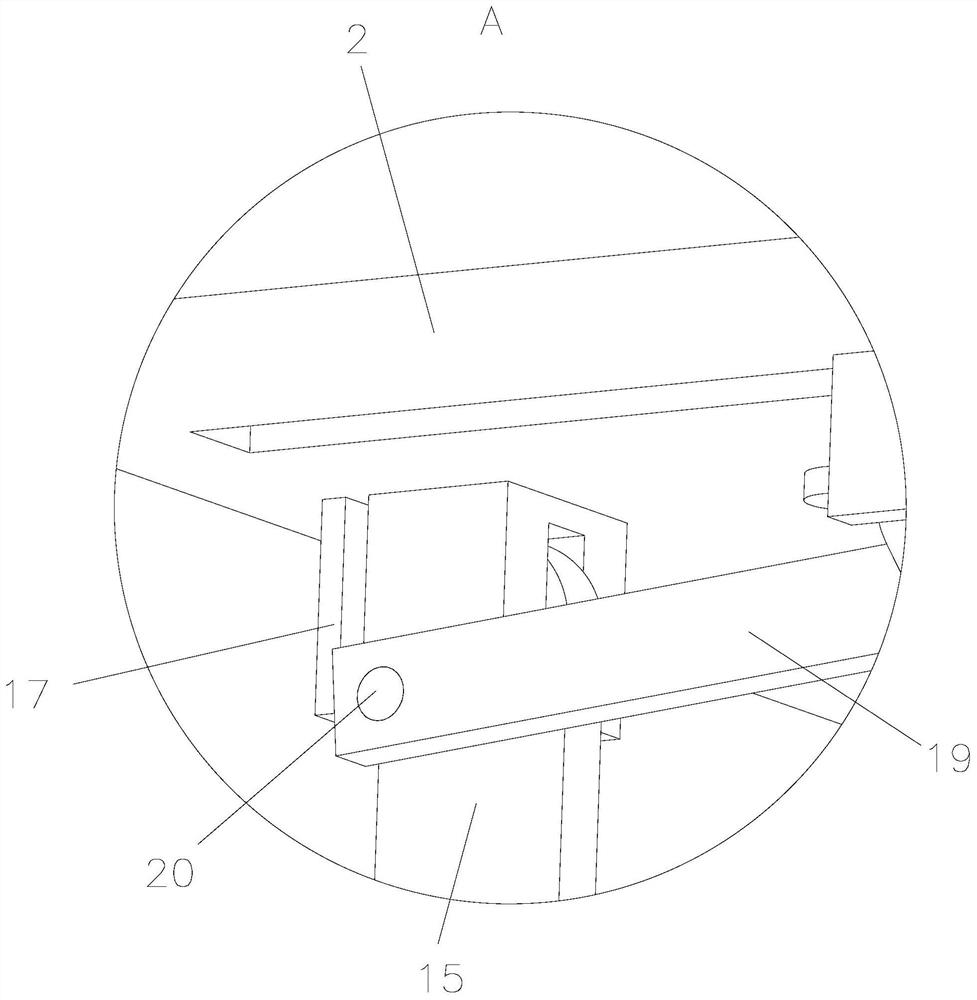

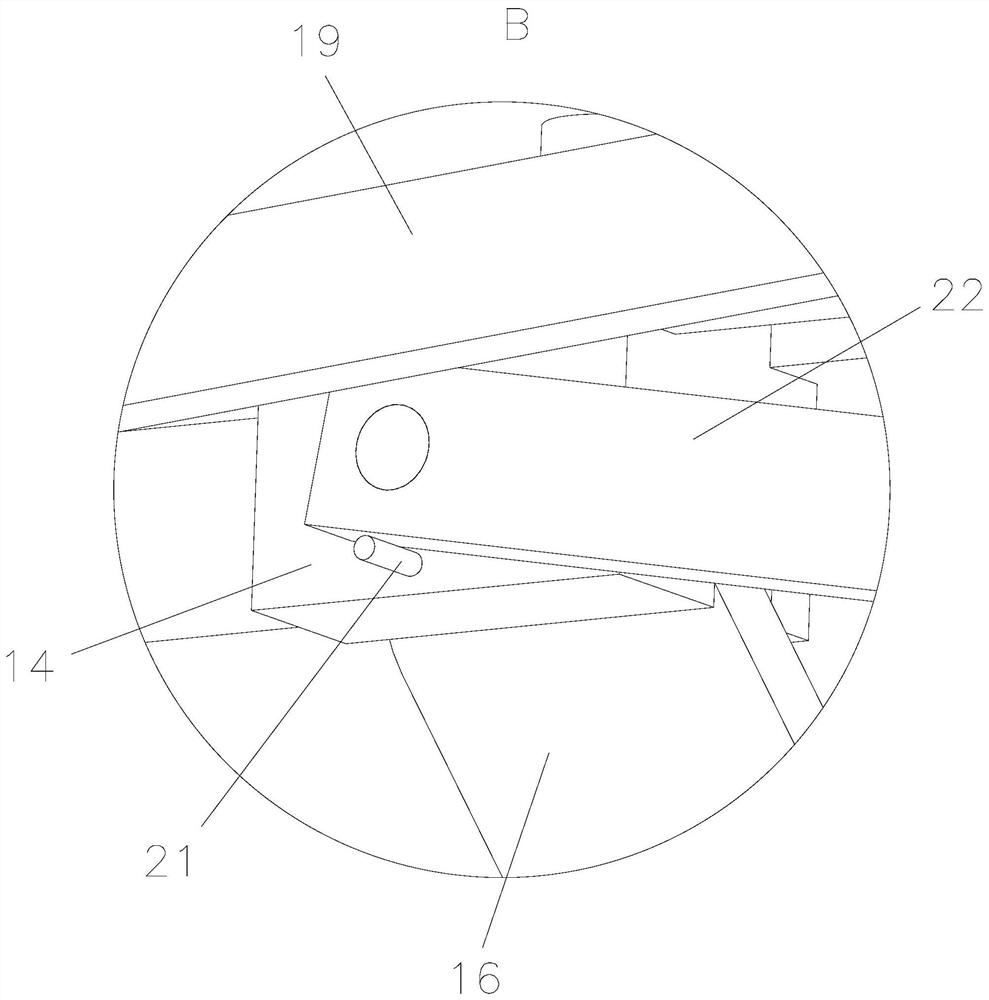

[0016] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0017] Such as figure 1 The shown industrial fire extinguishing robot with a lifting platform includes a movable car body 1 and a loading platform 2, the car body 1 is provided with a receiving controller 3, and the car body 1 is fixedly installed with The support base plate 4 is provided with two first guide rails 5 parallel to each other on the support base plate 4, and a first slide block 6 and a second slide block 7 are slidably installed in the two first guide rails 5. A motor 8 is fixedly installed on the body 1, and the protruding end of the motor 8 is fixedly connected with a two-way screw 9, and the first slider 6 and the second slider 7 in the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com