Movable type automatic rubber cutting device

An automatic cutting and mobile technology, applied in the direction of metal processing, etc., can solve the problems of uneven shape of the end face, high labor intensity, inconvenient cutting, etc., and achieve the effect of convenient cutting, lightening labor intensity, convenient distance and depth

Active Publication Date: 2017-11-28

ZHEJIANG KEDALI IND

View PDF6 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Due to the soft texture of the rubber, the cutting operation is performed manually in the traditional cutting, which is relatively labor-intensive, and due to the different positions of use, the shape of each rubber block is also different. For polygonal cutting, the traditional Cutting is inconvenient, and the shape of the end face formed by traditional cutting is uneven, which is inconvenient to connect with other parts. If the surface of the tool is very hot, it is also convenient for rubber cutting. Therefore, in order to solve these problems, an automatic cutting rubber is designed. equipment is necessary

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0025] Embodiment 2: The horizontal electrically controlled telescopic rod 20 can be replaced by a combination of a linear motor and a fixed rod, which can also achieve the horizontal telescopic effect, and other structures are the same as in Embodiment 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

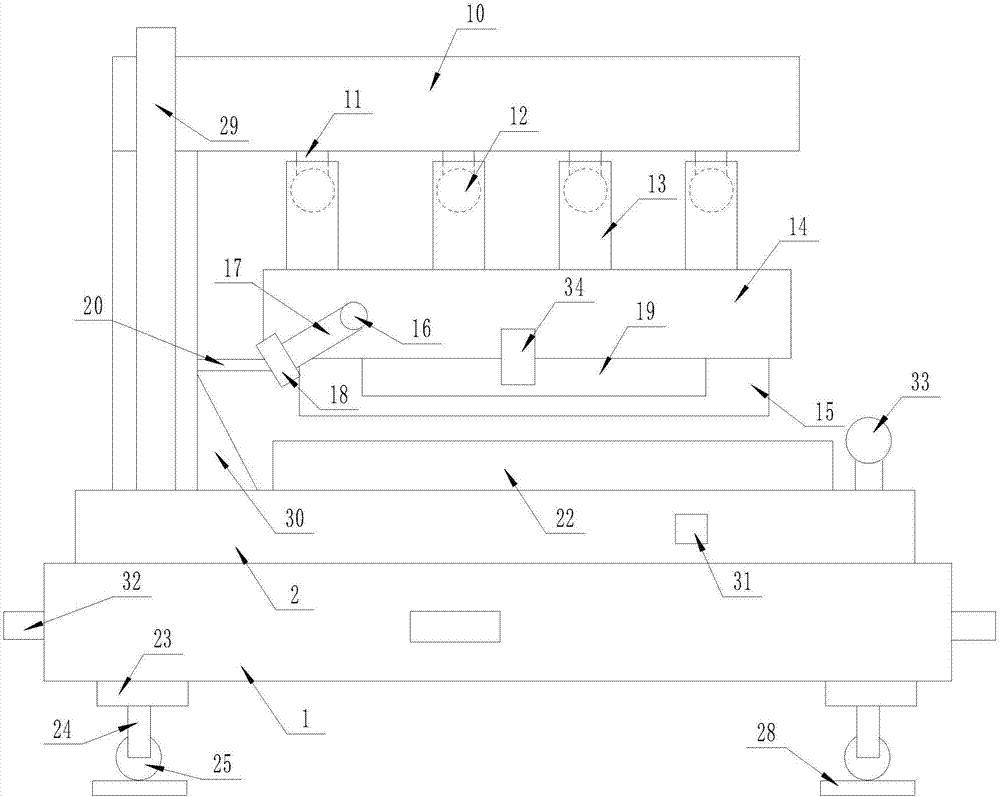

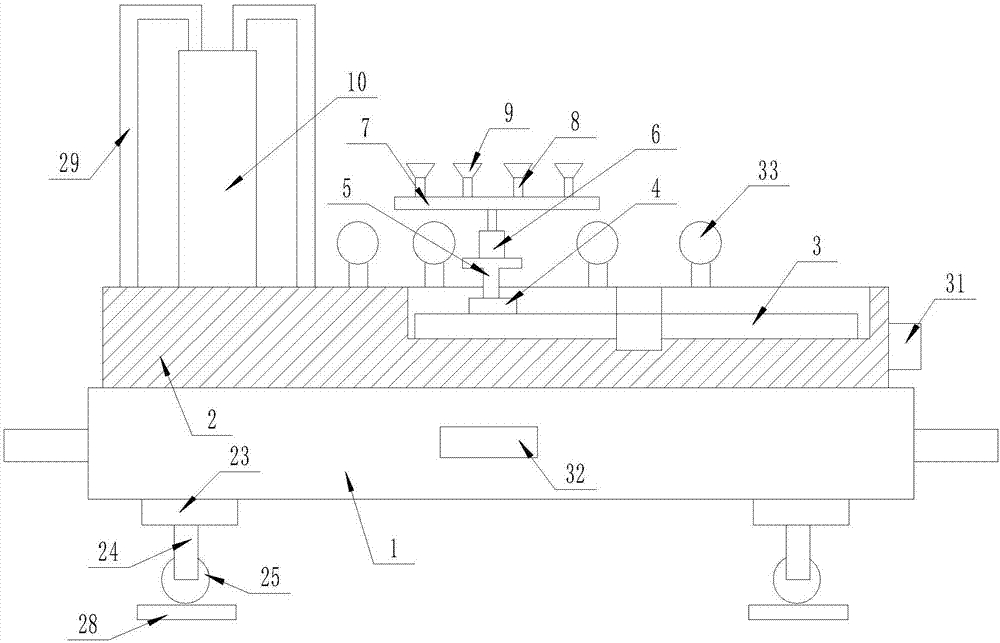

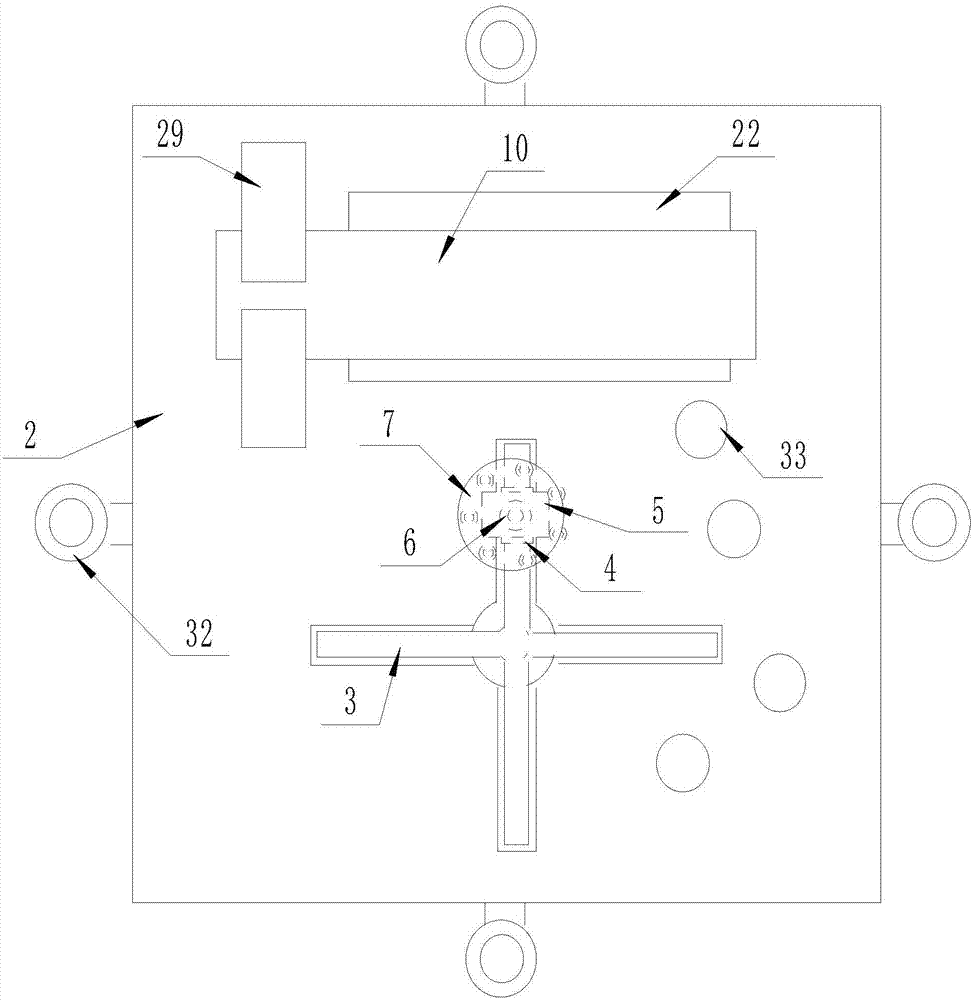

The invention discloses a movable type automatic rubber cutting device. The movable type automatic rubber cutting device comprises a strip-shaped bearing base; the upper surface of the strip-shaped bearing base is fixedly connected to a workbench; a movable cutting mechanism is arranged on the upper surface of the workbench; and a movable fixing mechanism is arranged on the lower surface of the strip-shaped bearing base. The movable type automatic rubber cutting device has the beneficial effects that the operation is relatively simple, block rubber to be cut only needs to be placed on the device, four-surface cutting or multi-surface cutting can be carried out through control, and therefore the cutting distance and the cutting depth can be adjusted conveniently, cutting is relatively convenient, the shape of the cut end surface is good, and the labor intensity can be reduced.

Description

technical field [0001] The invention relates to the field of rubber cutting, in particular to a mobile automatic rubber cutting device. Background technique [0002] Early rubber was latex taken from plants such as rubber trees and rubber grasses, which were processed into materials with elasticity, insulation, impermeability to water and air. High elastic polymer compound. [0003] Due to the soft texture of the rubber, the cutting operation is performed manually in the traditional cutting, which is relatively labor-intensive, and due to the different positions of use, the shape of each rubber block is also different. For polygonal cutting, the traditional Cutting is inconvenient, and the shape of the end face formed by traditional cutting is uneven, which is inconvenient to connect with other parts. If the surface of the tool is very hot, it is also convenient for rubber cutting. Therefore, in order to solve these problems, an automatic cutting rubber is designed. equipm...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B26D1/06B26D7/06B26D7/10B26D5/00

CPCB26D1/06B26D5/005B26D7/06B26D7/10

Inventor 肖涵

Owner ZHEJIANG KEDALI IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com