Electrical connectors for flat conductors

A technology of flat conductors and electrical connectors, applied in the direction of connections, circuits, coupling devices, etc., can solve the problems of not getting a click feeling, misidentifying the position of the operating lever, and difficult operation of the operating lever, and achieve the effect of preventing grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

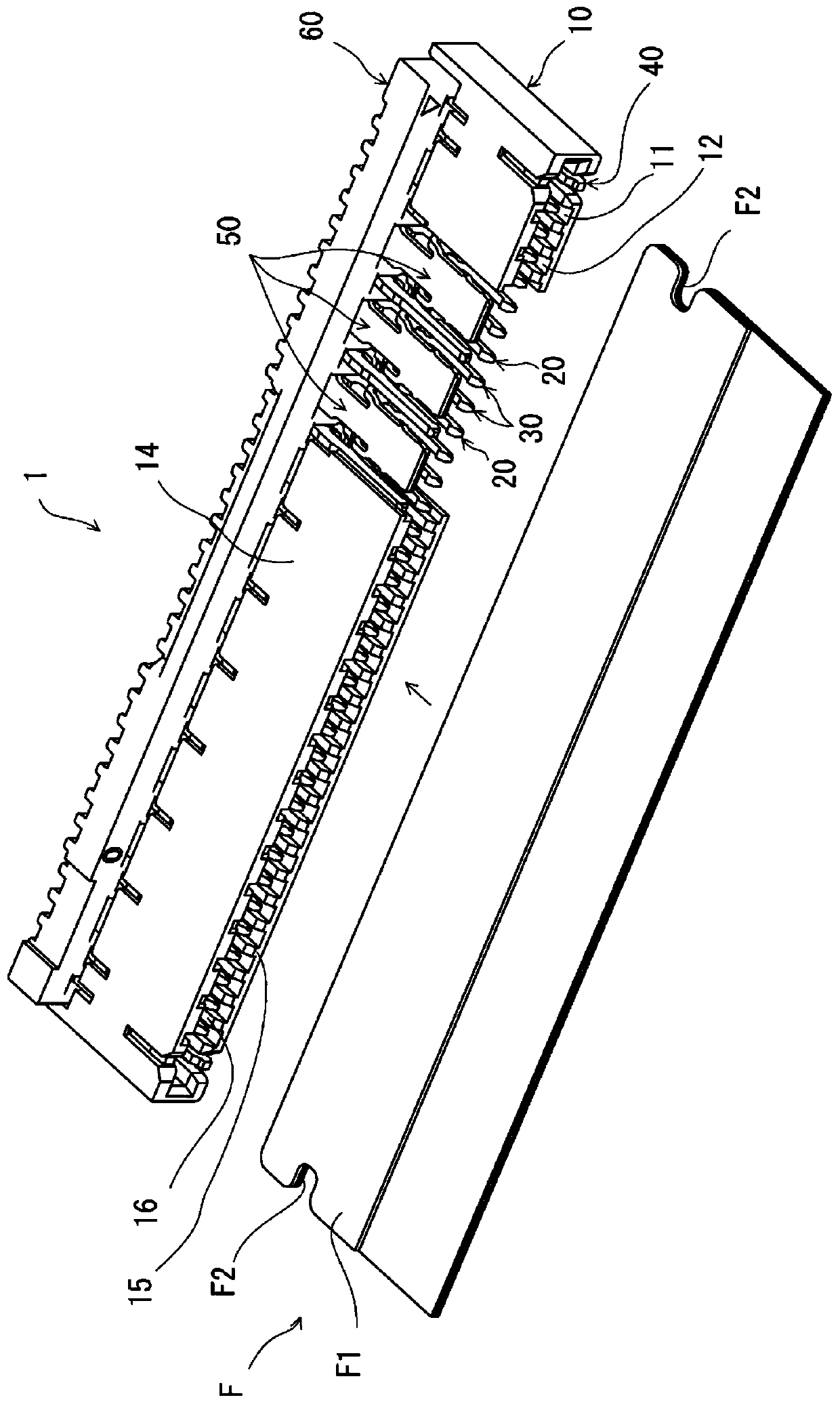

[0030] figure 1 It is an overall perspective view showing the flat conductor electrical connector 1 (hereinafter referred to as "connector 1") and the flat conductor F according to the present embodiment, and a part of the housing 10 described later is omitted. The connector 1 is disposed on a mounting surface of a circuit board (not shown), and the flat conductor F is inserted and removed in one direction parallel to the mounting surface, that is, the front-rear direction.

[0031] The flat conductor F is at its front end ( figure 1 The upper right edge part of the part close to the connector 1) has a connecting part with the above-mentioned connector 1, and faces rearward ( figure 1 Middle left bottom) extends long, but only the part up to the position immediately behind the connection part is shown in the figure, and the illustration of the part behind this position is omitted. With respect to the above-mentioned flat conductor F, in this embodiment, the coating on the lo...

no. 2 approach >

[0091] In the first embodiment, the restricting portion 15C is formed on the bottom wall 15 of the housing 10 in the terminal-free range in the direction of the terminal arrangement, and restricts the movable member 60 from descending by a predetermined amount or more. The lower end of the movable member in the non-terminal range is positioned lower than the lower end of other ranges without providing a restricting portion as in the first embodiment, thereby restricting the lowering of the movable member by a predetermined amount or more. In this regard, It is different from the first embodiment. In this embodiment, reference numerals with "100" added to the reference numerals in the first embodiment are assigned to parts corresponding to the first embodiment, and the differences from the first embodiment will be mainly described. .

[0092] Figure 10 It is an overall perspective view showing an electrical connector 101 for a flat conductor (hereinafter referred to simply a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com