Production unit automatically breaking off hub casting lug

A wheel hub and automatic technology, which is applied in the field of production units that automatically break off the casting lugs of the wheel hub, can solve the problems of no safety guarantee, personnel fatigue, heavy wheel hub weight, etc., and achieve the goal of liberating production work, increasing safety guarantees, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

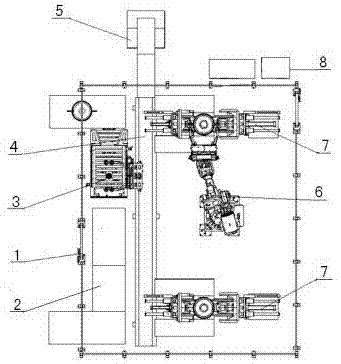

[0016] Depend on figure 1 It is known that a production unit for automatically breaking casting lugs of wheel hubs consists of a protective fence 1, a loading and unloading logistics line 2, a servo identification and positioning machine for casting lugs 3, an automatic waste discharge device 4, a waste box 5, a robot 6, and breaking lugs. Machine 7 and control box 8. The production unit is surrounded by a protective fence 1. The loading and unloading logistics line 2 is provided with a material inlet and a material outlet. The waste material discharge equipment 4 is connected with a waste material box 5, and is arranged on one side of the two pouring ear breaking machines 7, the robot system 6 operates in the production unit, and the control box 8 is arranged on one side of the production unit.

[0017] Its working process is:

[0018] 1) The parameters of the robot system 6 are set, and there is no alarm, and the robot 6 starts;

[0019] 2) The conveying logistics line 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com