Composite insulator fatigue degree evaluation method based on video difference analysis

A technology of composite insulators and difference analysis, applied in the testing of machines/structural components, measuring devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

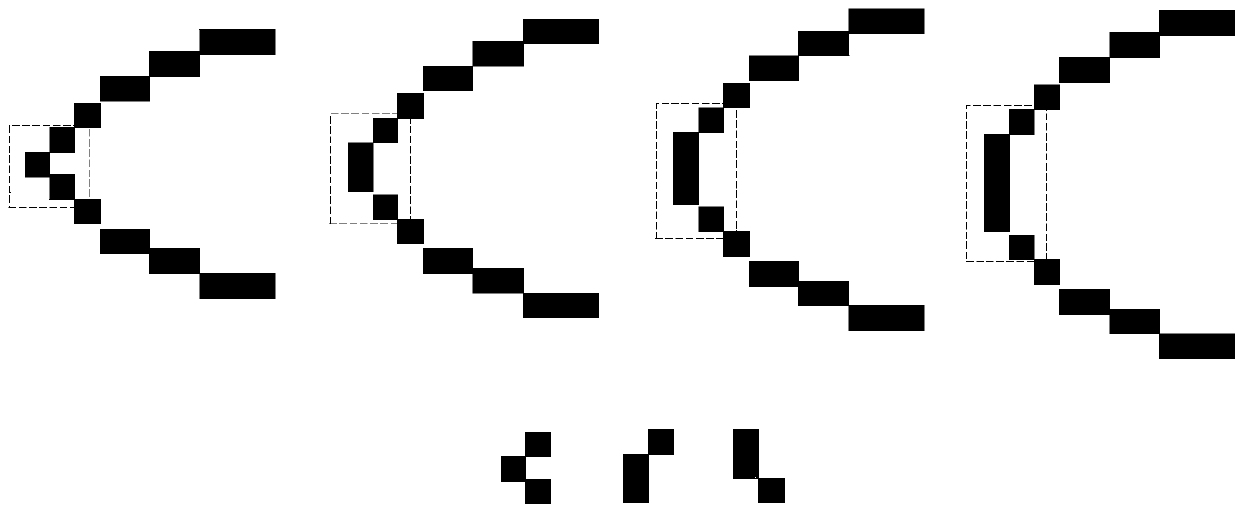

[0067] A method for evaluating the fatigue degree of composite insulators based on video difference analysis, specifically implemented according to the following steps:

[0068] Step 1, collect video images and wind speed waveforms. The specific method is: through the calibrated 100Hz fixed-focus high-speed camera with pan-tilt and wind speed sensor installed on the site iron tower to obtain the real-time vibration video and wind speed waveform of the composite insulator under strong wind, according to For the mainstream wind direction in the strong wind area, install a calibrated fixed-focus high-speed camera with a pan-tilt and a wind speed sensor at the corresponding position of the iron tower where the composite insulator is located. Since the natural frequency of the composite insulator used in the UHV transmission line in the strong wind a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com