Bearing lock and locking and unlocking method

A locking and unlocking technology, applied in the field of unmanned aerial vehicle systems, can solve the problems of complex structure, difficult automation and heavy weight of the door switch drive mechanism, and achieve the effect of light weight, ensuring connection strength and rigidity, and strong bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

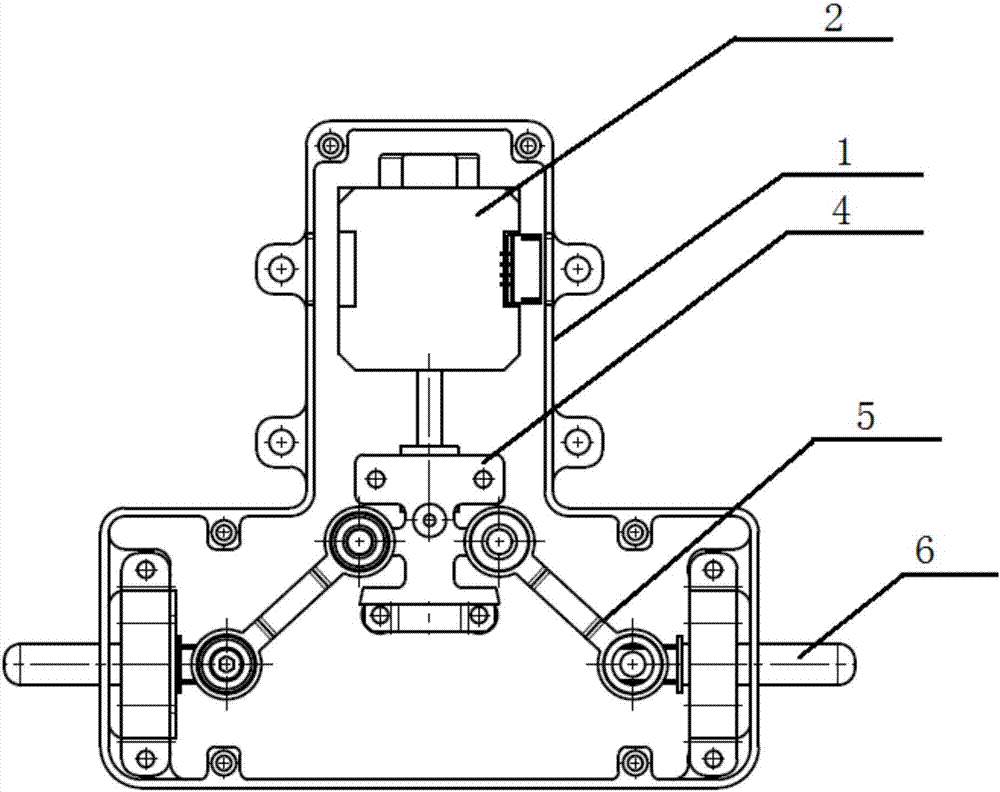

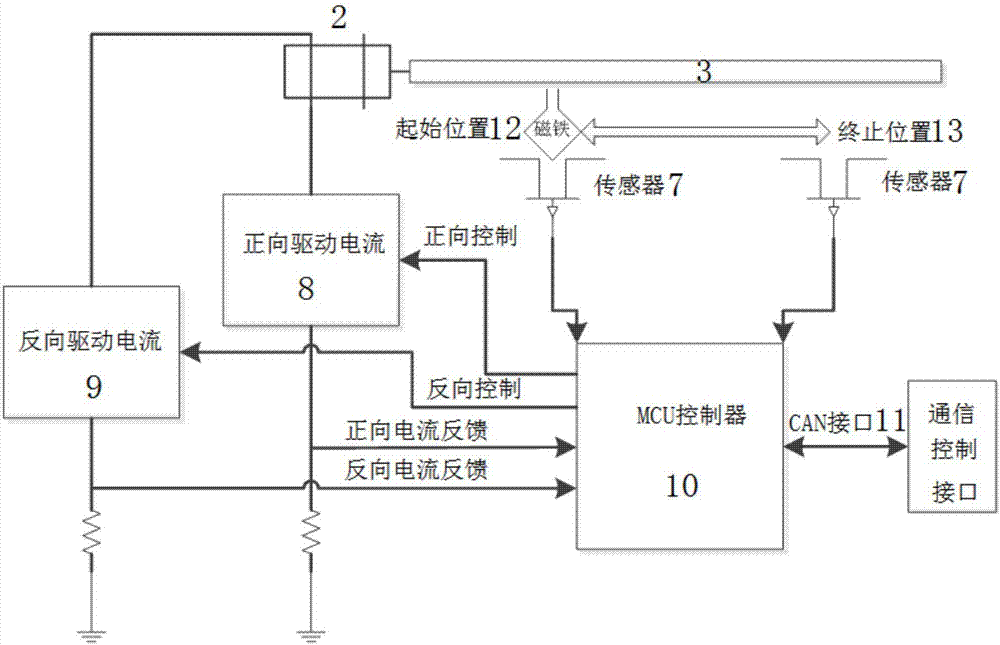

[0042] Such as Figure 1-4 As shown, the description method of this embodiment is described by taking the direction shown in the drawings as an example. This embodiment provides a load lock, which includes a convex housing 1, a geared motor 2 is arranged in the housing 1, the output shaft of the geared motor 2 is connected with a lead screw 3, and the lead screw 3 is threaded with a nut seat 4, When the leading screw 3 rotates, the nut seat 4 moves between the initial position 12 and the end position 13 along the leading screw 3, and the two sides of the nut seat 4 are respectively connected with the rocking arm 5 through the rotating shaft through the rotating shaft, and the nut seat 4 and the rocking arm 5. The bearing at the rotating joint is a ball bearing. The rocking arm 5 is respectively connected to a lock pin 6 through a rotating shaft. The bearing at the rotating joint between the rocking arm 5 and the locking pin 6 is a linear motion bearing. The end of the locking ...

Embodiment 2

[0059] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0060] The carrying lock of the present embodiment comprises a convex housing 1, a geared motor 2 is arranged in the housing 1, the output shaft of the geared motor 2 is connected with a lead screw 3, the lead screw 3 is threaded with a nut seat 4, and the lead screw 3 When rotating, the nut seat 4 moves between the initial position 12 and the end position 13 along the lead screw 3, the two sides of the nut seat 4 are respectively connected with the rocker arm 5 by the rotating shaft through the rotating shaft, and the nut seat 4 is rotationally connected with the rocker arm 5 The bearing at the position is a ball bearing, and the rocker arm 5 is connected with a lock pin 6 through a rotating shaft, and the bearing at the rotation joint between the rocker arm 5 and the lock pin 6 is a linea...

Embodiment 3

[0069] The features of this embodiment that are the same as those of Embodiment 1 will not be described in detail. The features of this embodiment that are different from Embodiment 1 are:

[0070] In the carrying lock of this embodiment, the power mechanism is sufficient to reciprocate along the starting position and the end position in the linear direction. The power mechanism in this implementation is a cylinder and a fixed seat. The piston rod of the cylinder is connected to the fixed seat. The two sides are connected in rotation with the rocker arm through the rotating shaft respectively, and the bearings at the rotation connection of the fixed seat and the rocker arm are ball bearings.

[0071] The controller controls the start position and end position of the reciprocating motion of the power mechanism through the sensor.

[0072] A method for locking and unlocking a bearing lock is provided, comprising the following steps:

[0073] The piston rod of the air cylinder r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com