Wide-breadth multi-guide-bar jacquard warp knitting machine with yarn pressing plate

A technology of yarn pressing board and warp knitting machine, which is applied in flat warp knitting machine, warp knitting, textile and paper making, etc. It can solve problems such as insufficient rigidity, achieve the effects of reducing labor costs, improving economic benefits, and running smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

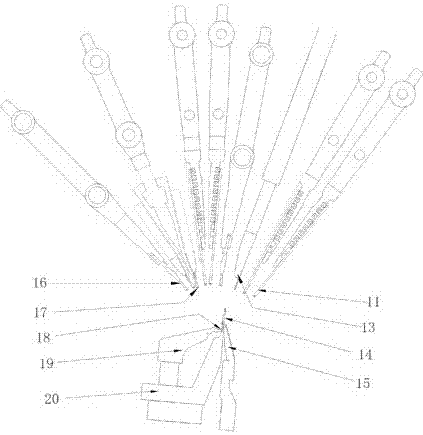

[0020] Referring to the accompanying drawings, a wide-width multi-bar jacquard warp knitting machine with a yarn pressing plate is characterized in that the width of the warp knitting machine is at least 240 inches, and can reach 268 inches, which is twice the width of ordinary models. . The left wallboard (2a) is fixed on the left side of the body (1), the right wallboard (2b) is fixed on the right side of the body (1), and the middle wallboard (2) is installed on the left wallboard (2a), right on the body (1) between the wall panels (2b). The main beam (9) of the warp knitting machine is jointly supported by the left wallboard (2a), the right wallboard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com