Preparation of composite material NH2-UIO-66@TpPa-1 and water-photodecomposed hydrogen production

A technology of NH2-UIO-66 and composite materials, applied in hydrogen/synthesis gas production, organic compound/hydride/coordination complex catalyst, hydrogen, etc., can solve the problem of low efficiency of hydrogen production by photolysis of water, and achieve The effect of improving the hydrogen production performance of photolysis water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

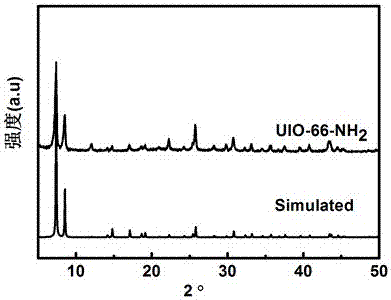

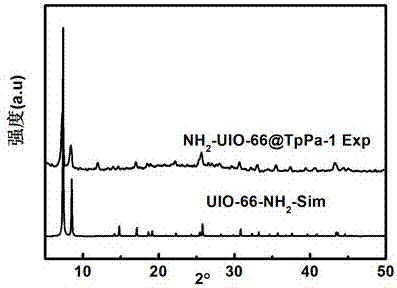

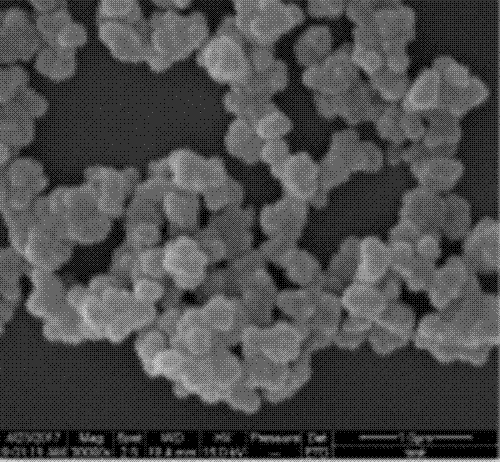

[0021] Specific embodiment one: a kind of NH in this embodiment 2 - The preparation of the UIO-66@TpPa-1 composite was accomplished as follows:

[0022] 1. NH 2 - Preparation of UIO-66;

[0023] 2. NH 2 -Preparation of UIO-66@TpPa-1 composite: NH 2 -UIO-66, 1,3,5-trialdehyde phloroglucinol and p-phenylenediamine were added to a heat-resistant glass tube, followed by 1,3,5-trimethylbenzene and 1,4-dioxane The mixed solution of acetic acid and acetic acid is ultrasonically treated at an ultrasonic frequency of 35~45KHz for 20~30min, degassed by three freeze-thaw cycles in a liquid nitrogen bath, sealed and heated at 120°C for 24~96h, filtered and washed with tetrahydrofuran Three times, dry to get NH 2 - UIO-66@TpPa-1 composite material;

[0024] NH mentioned in step 2 2 - The mass ratio of UIO-66, 1,3,5-trialdehyde phloroglucinol and p-phenylenediamine is 1:1.15:0.85;

[0025] The volume ratio of 1,3,5-trimethylbenzene, 1,4-dioxane and acetic acid in step 2 is 1:1:0.33;...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 2, ultrasonic treatment is performed for 20 minutes at an ultrasonic frequency of 35 KHz, and other steps and parameters are the same as Embodiment 1.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 2, ultrasonic treatment is performed for 30 minutes at an ultrasonic frequency of 35 KHz, and other steps and parameters are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com