A highly sensitive online detection system and method for tiny metal particles

A metal particle and detection method technology, applied in radio wave measurement system, measurement device, electric/magnetic exploration, etc., can solve the problem of low sensitivity, achieve the effect of improving sensitivity and enhancing detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

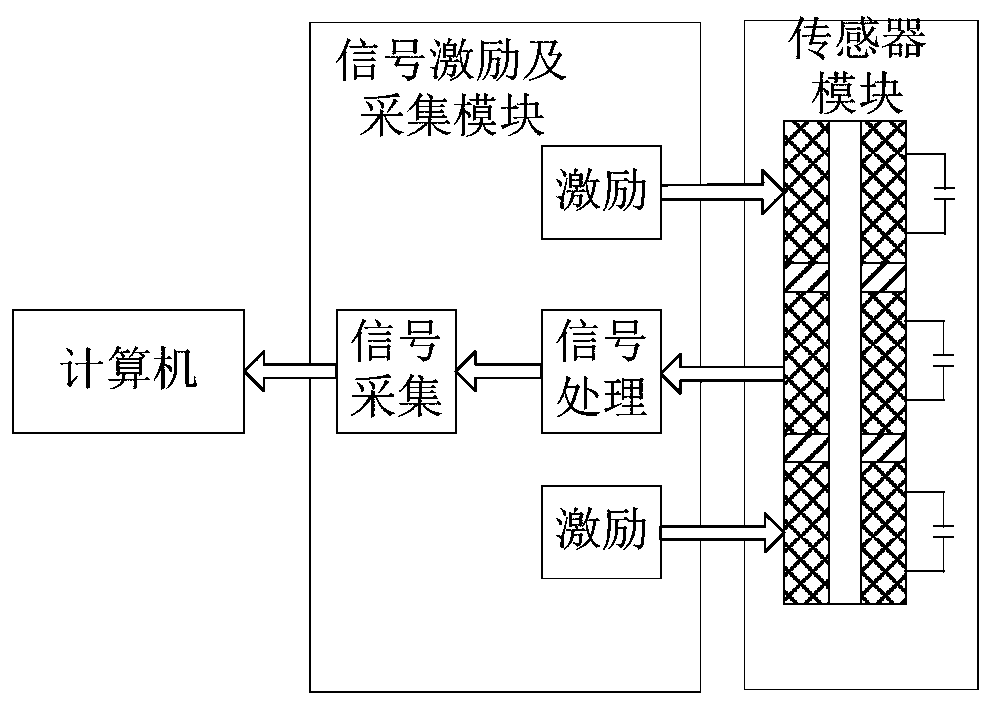

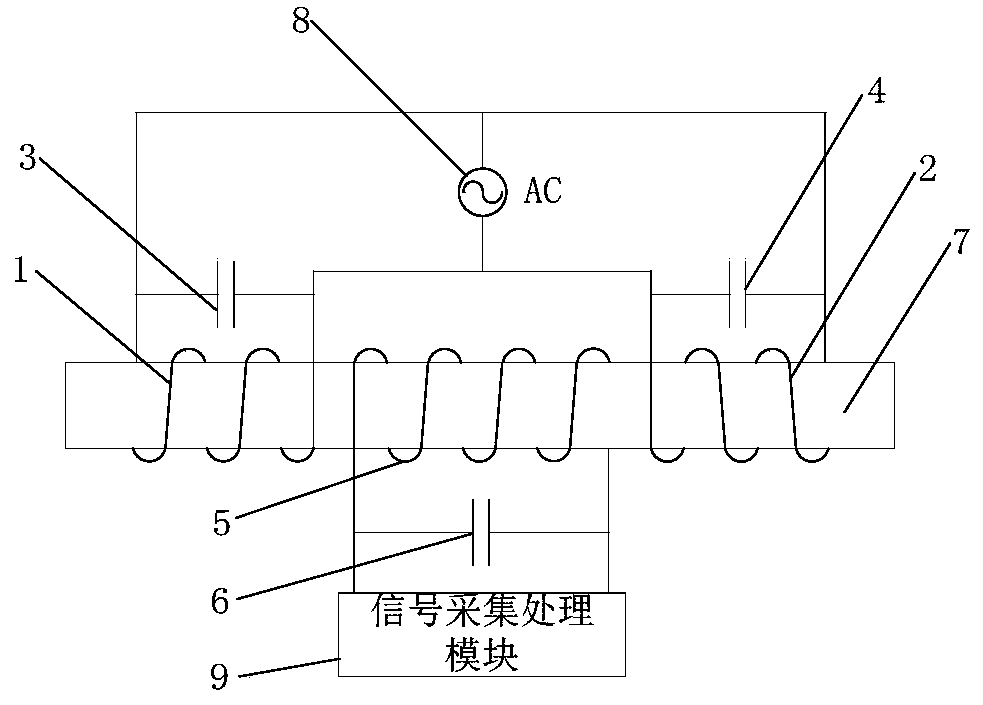

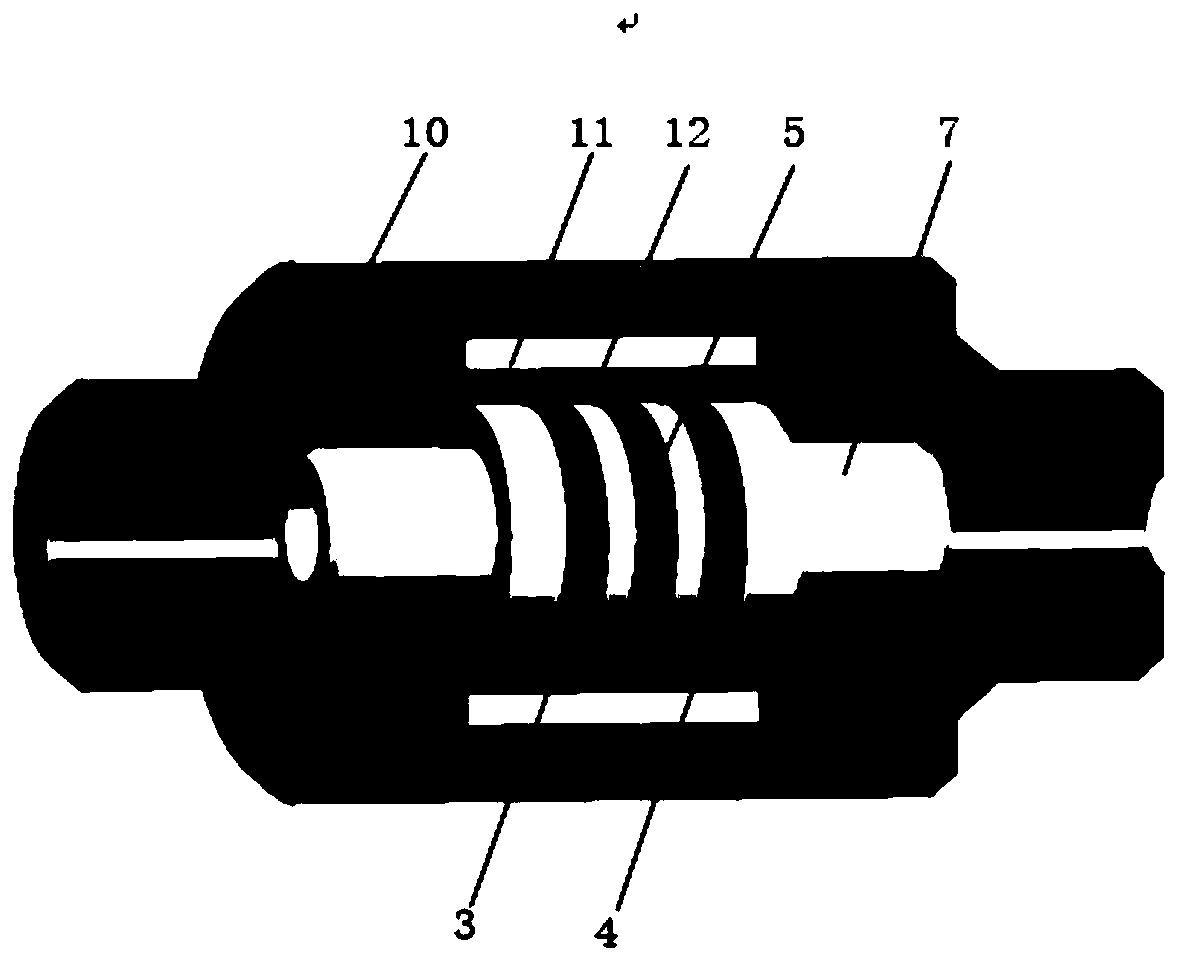

[0041] In the present invention, the same sinusoidal alternating current is passed into two excitation coils wound in opposite directions, and dynamically changing magnetic fields of equal magnitude and opposite directions are respectively generated inside the two excitation coils. The induction coil is located in the middle of the two excitation coils. When there is no metal When the particles pass through the sensor, the magnetic field strength at the induction coil is zero, so no induced electromotive force is output. When the ferromagnetic particles pass through the sensor, the magnetic field inside the coil will be enhanced. When the non-ferromagnetic particles enter the sensor, the magnetic field inside the coil will be weakened. The effect causes the magnetic field of the two excitation coils to be unbalanced, the magnetic field of the induction coil is not zero, and the induced electromotive force is output. The present invention will be described in detail below in con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com