Improvement scheme of nozzle outlet of fuel engine carburetor

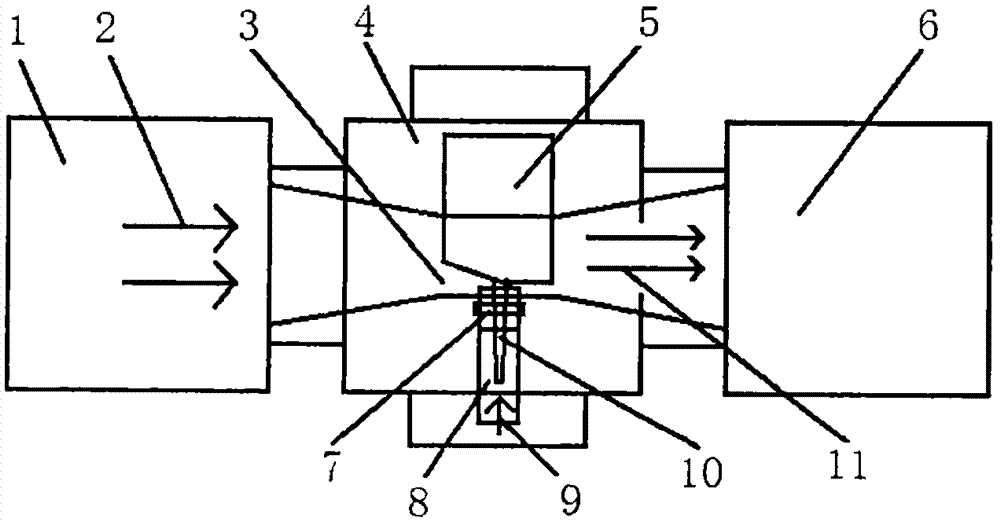

A fuel engine and nozzle outlet technology, which is applied to carburetors, engine components, machines/engines, etc., can solve the problems of insufficient and uneven mixing and atomization of fuel and air, and achieve sufficient and fast combustion with low cost investment , The effect of large power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

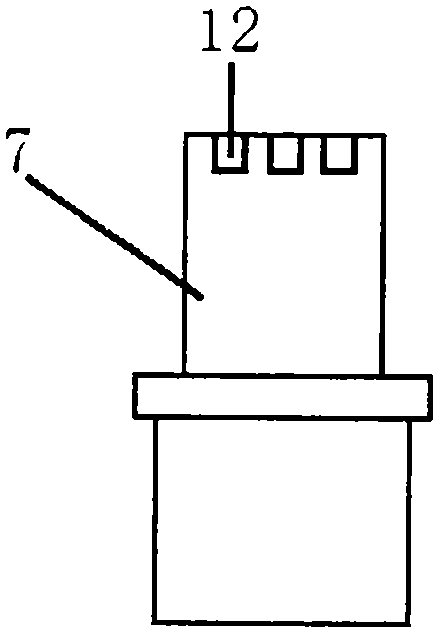

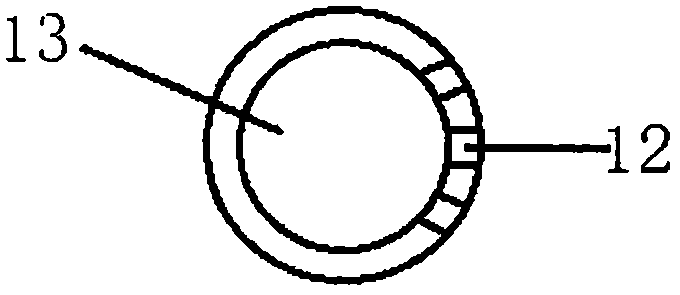

[0015] On the outlet surface of the carburetor nozzle, process a plurality of diversion grooves radially with a fan of no more than 180 degrees, and install the nozzle with the diversion grooves facing the engine side.

[0016] Description: The present invention can be used in fuel engine carburetors.

[0017] The above-mentioned embodiments of the present invention are merely examples of the present invention, rather than limiting the implementation of the present invention. For those skilled in the art, other changes and modifications in different forms can be made on the basis of the above description, and all implementation modes cannot be exhaustively listed here. All the technical proposals and extensions of the plurality of diversion grooves arranged on the outlet surface of the carburetor nozzle against the engine side still belong to the scope of protection of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com