A sewage treatment device

A sewage treatment device and sliding joint technology, applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high labor intensity, slow speed, and small range of hand-sprinkled alum , to achieve the effect of preventing clogging and improving the crushing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

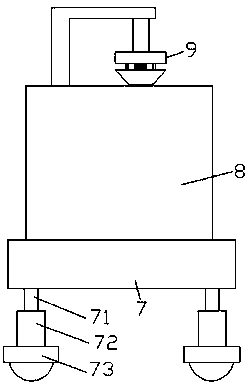

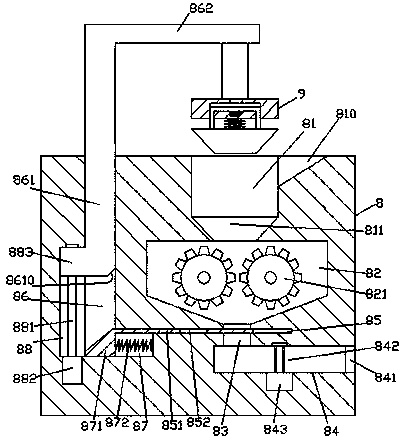

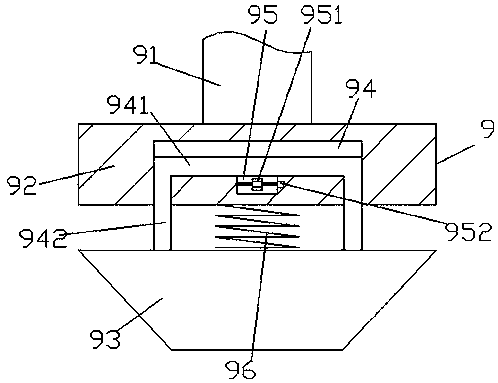

[0019] Such as Figure 1-Figure 6 As shown, a kind of sewage treatment device of the present invention comprises a base 7 and an alum feeding machine 8 installed on the top of the base 7, the top surface of the alum feeding machine 8 is provided with an input cavity 81, and the input cavity The bottom of 81 communicates with a funnel groove 811, and the top of the inner wall on the right side of the feeding chamber 81 is provided with a beveled edge groove 810. Device 821, the bottom of the crushing chamber 82 is connected with a connection port 83, and the bottom of the connection port 83 is connected with an alum feeding chamber 84 extending to the right, and an alum feeding device is arranged in the alum feeding chamber 84. The connecting port 83 is provided with a second sliding joint groove 85 extending left and right, and the left side of the second sliding joint groove 85 is connected with the tail end and is provided with a first guiding groove 87 extending downward. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com