Hydroponic shelf module and hydroponic shelf thereof

A hydroponic rack and hydroponic technology, applied in botany equipment and methods, soilless cultivation, cultivation, etc., can solve the problems affecting the overall plant factory space utilization rate, low planting board space utilization rate, and operating cost impact, etc. Reach the effect of reducing light sources and air-conditioning circulation equipment, better growth quality, and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

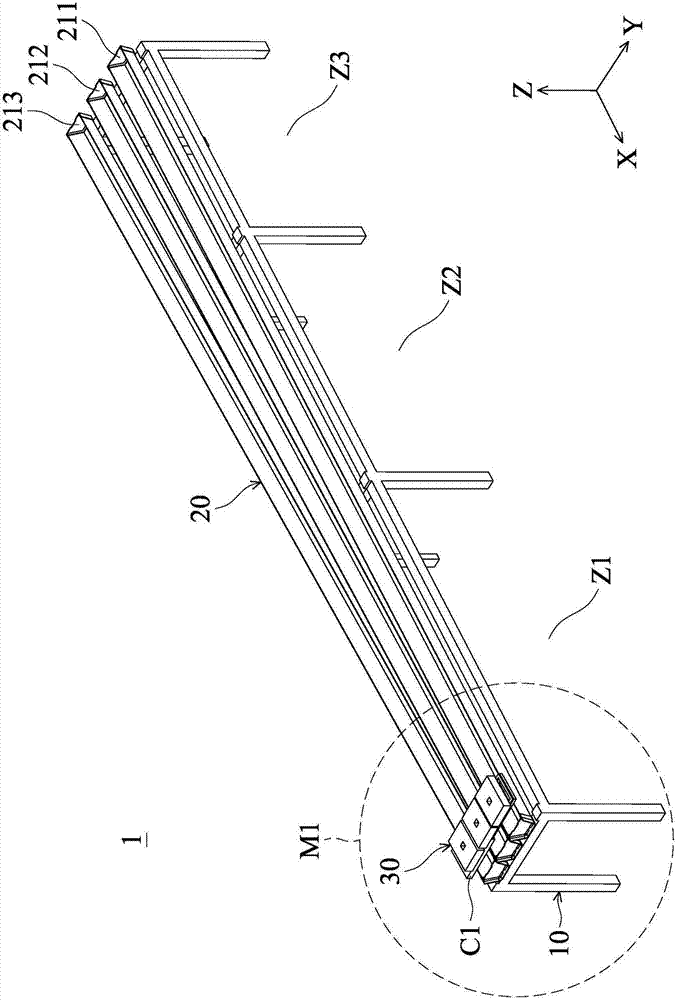

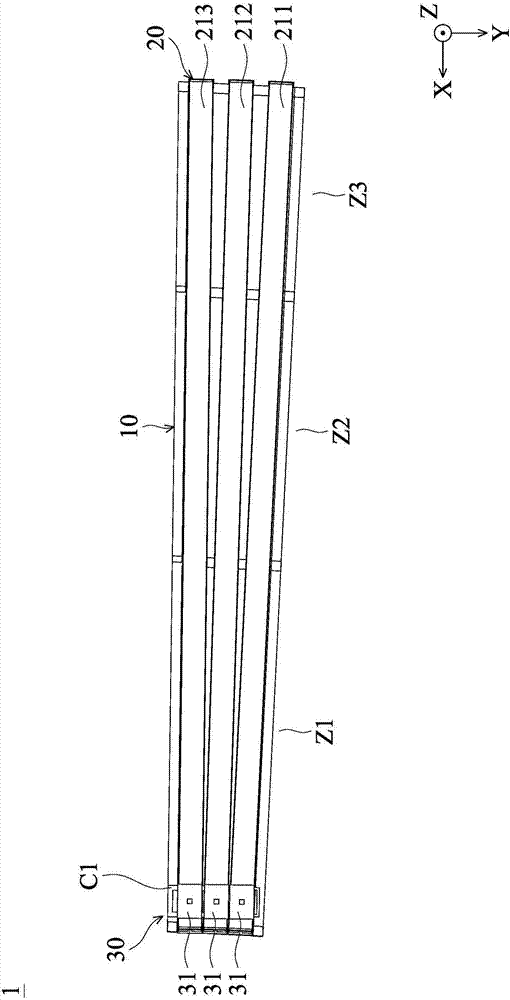

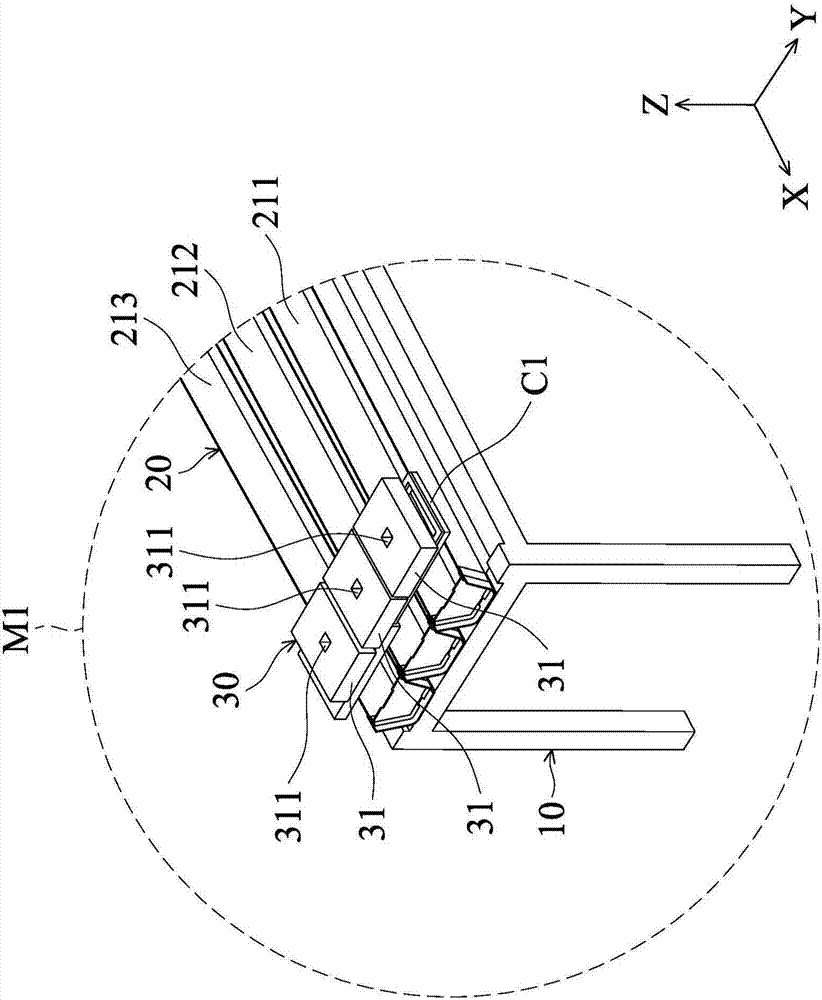

[0062] Please refer to it first Figure 1A-Figure 1C ,among them Figure 1A Is a perspective view of a hydroponic rack 1 according to an embodiment of the present invention, Figure 1B Then Figure 1A The top view of the hydroponic rack 1 in Figure 1C Then Figure 1A Enlarged view of M1 in the middle. Such as Figure 1A As shown, the aforementioned hydroponic rack 1 includes a layer frame 10, a water bed 20, a planting plate group 30, a first zone Z1, a second zone Z2, and a third zone Z3. The aforementioned layer frame 10 is used to support the water bed 20. , The first, second, and third zones Z1, Z2, and Z3 are connected to each other in sequence.

[0063] Such as Figure 1B As shown, the water bed 20 has a first water channel 211, a second water channel 212, and a third water channel 213. The water bed 20 is used to contain fluid (such as water or nutrient solution); the planting plate group 30 is slidable The method is arranged on the water bed 20, and has a plurality of plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com