Thin layer expansion groove and thin layer expansion device

A technology for developing grooves and thin layers, applied in the field of biology, can solve the problems of slow unfolding speed of organic solvents, and achieve the effect of avoiding uneven unfolding and increasing the scope of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

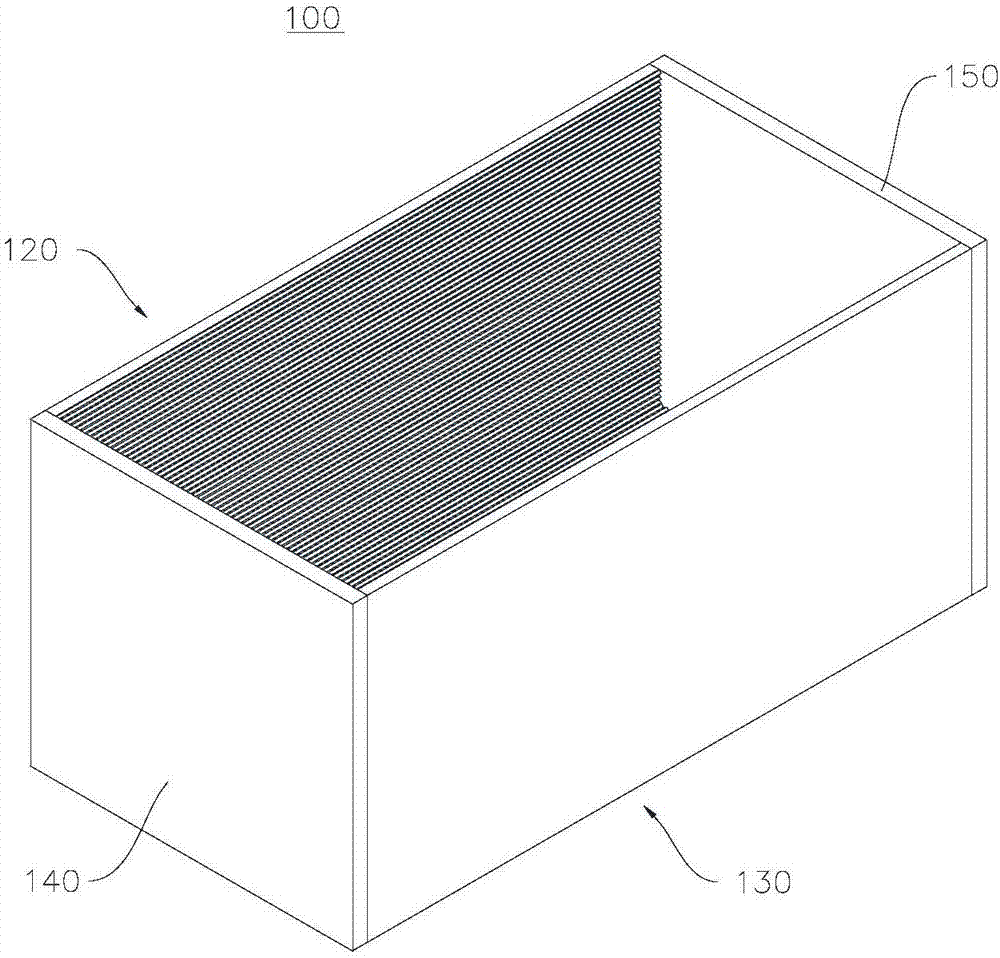

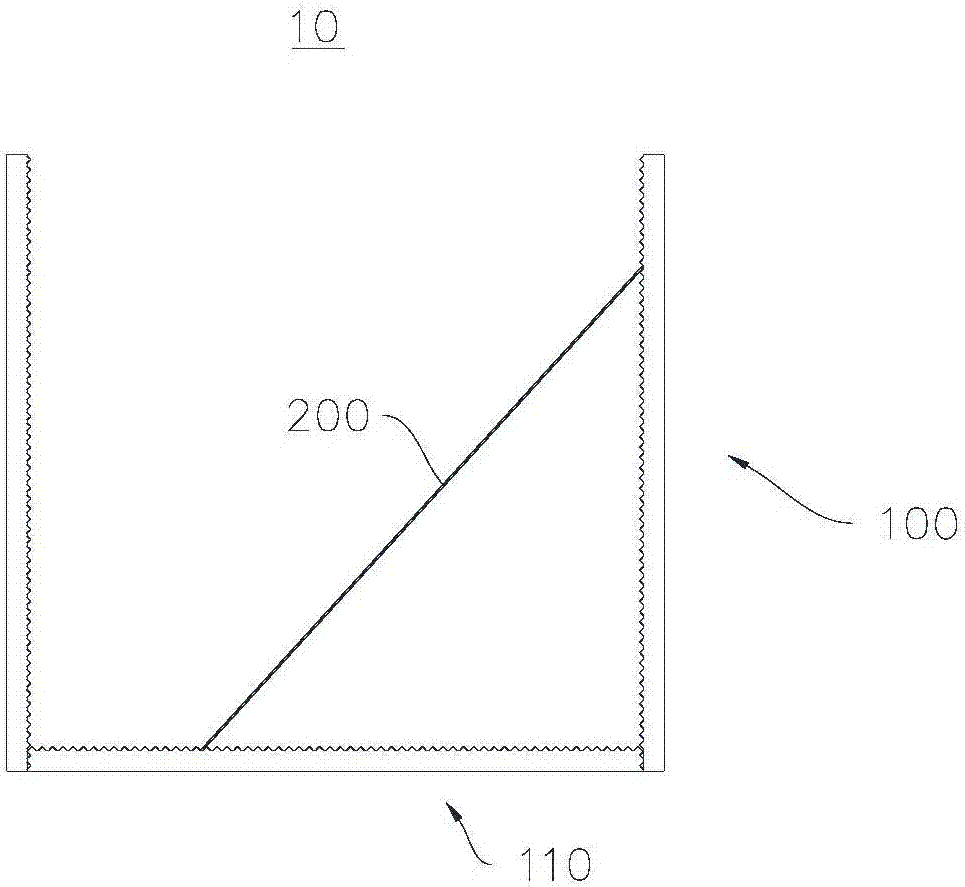

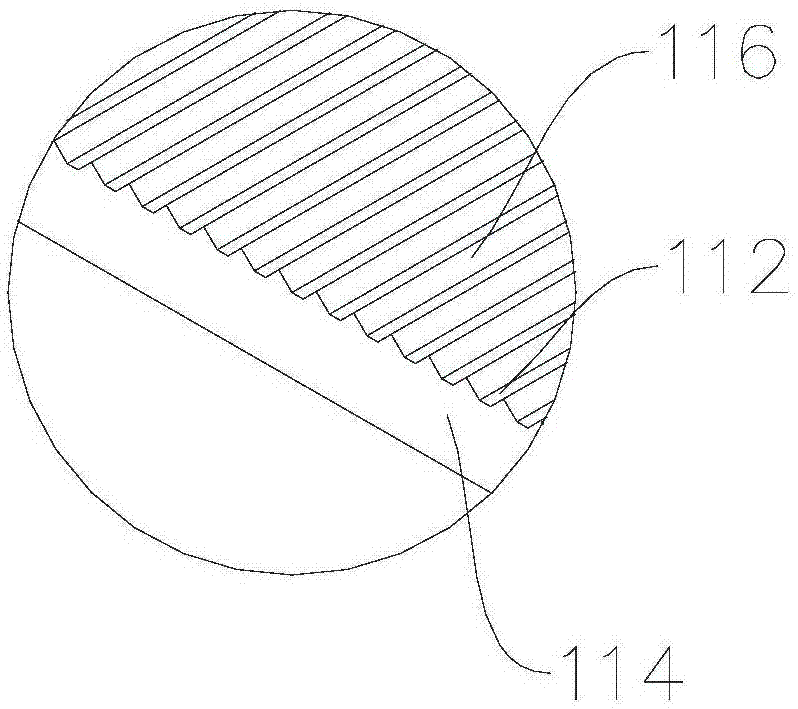

[0031] The thin-layer development device is used to enable organic solvents to develop, which is convenient for the test and observation of organic solvents. However, different organic solvents have different viscosities, which will lead to different development speeds when using the same thin-layer development device for different organic solvents. The efficiency of the development of the organic solvent is lower.

[0032] There are three types of existing thin-layer development devices: vertical type, horizontal type and automatic type. Different solvents have different viscosities. In the existing thin-layer development devices, different solvents have different development speeds. The use of a vertical thin-layer development device for large solvents will make the movement time longer, and the use of a horizontal thin-layer development device will cause the solvent to slide down quickly, which cannot be effectively developed in the thin-layer development device, resulting i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com