Multi-flow-path three-casing-pipe heat exchanger of direct heating type heat-pump water heater

A heat pump water heater, multi-process technology, applied in the direction of evaporator/condenser, lighting and heating equipment, refrigeration components, etc., can solve the problems of difficult installation, low heat exchange efficiency, economical efficiency, and reduced convenience, and achieve volume and Small footprint, increase the temperature difference between inlet and outlet, and reduce the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

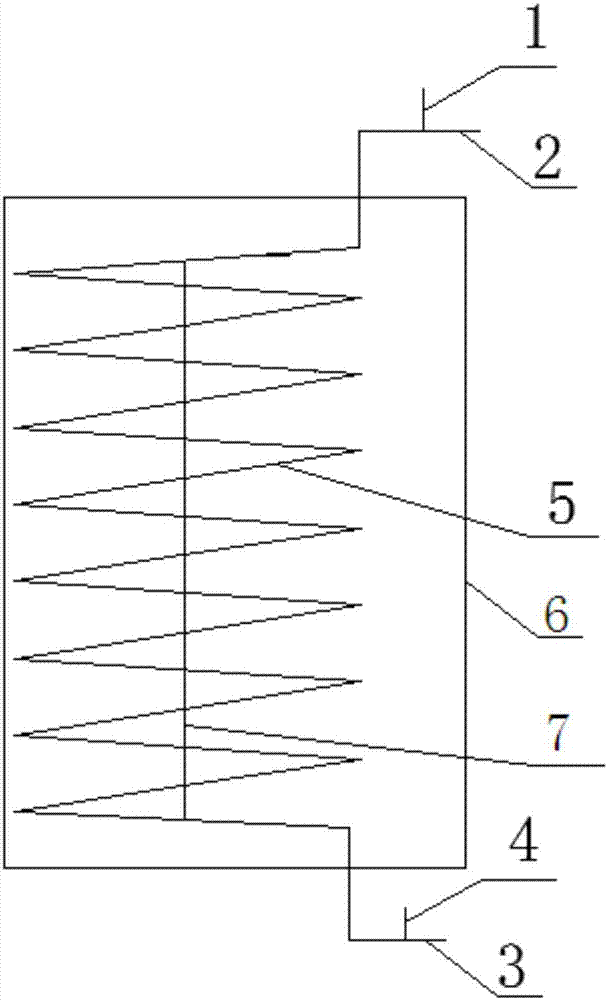

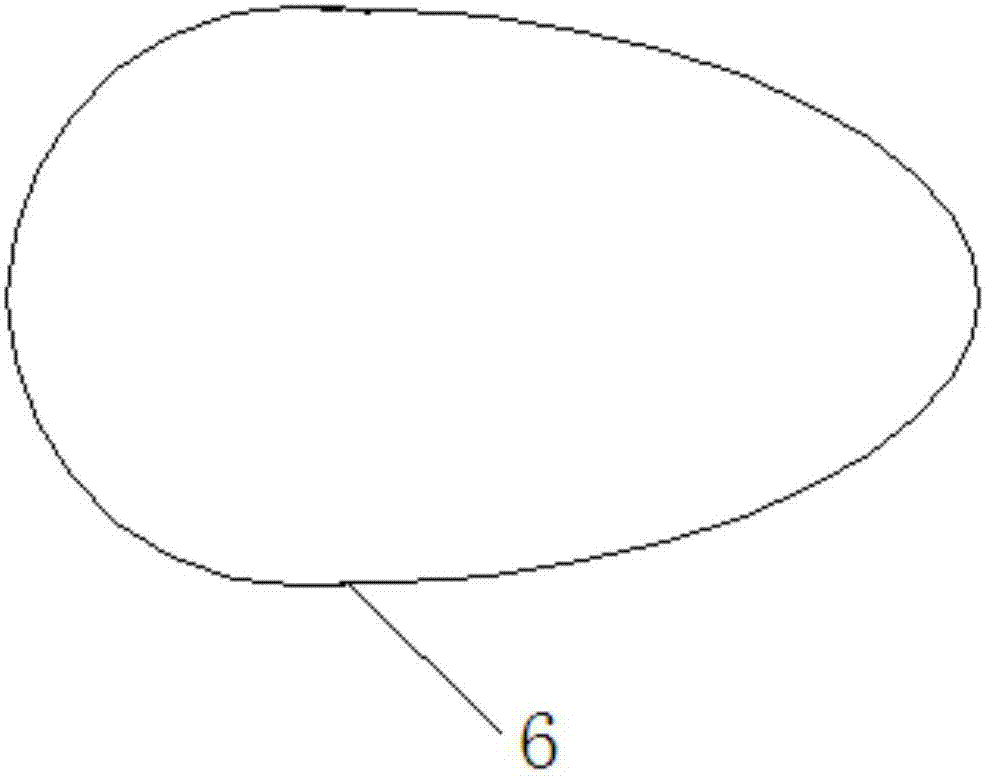

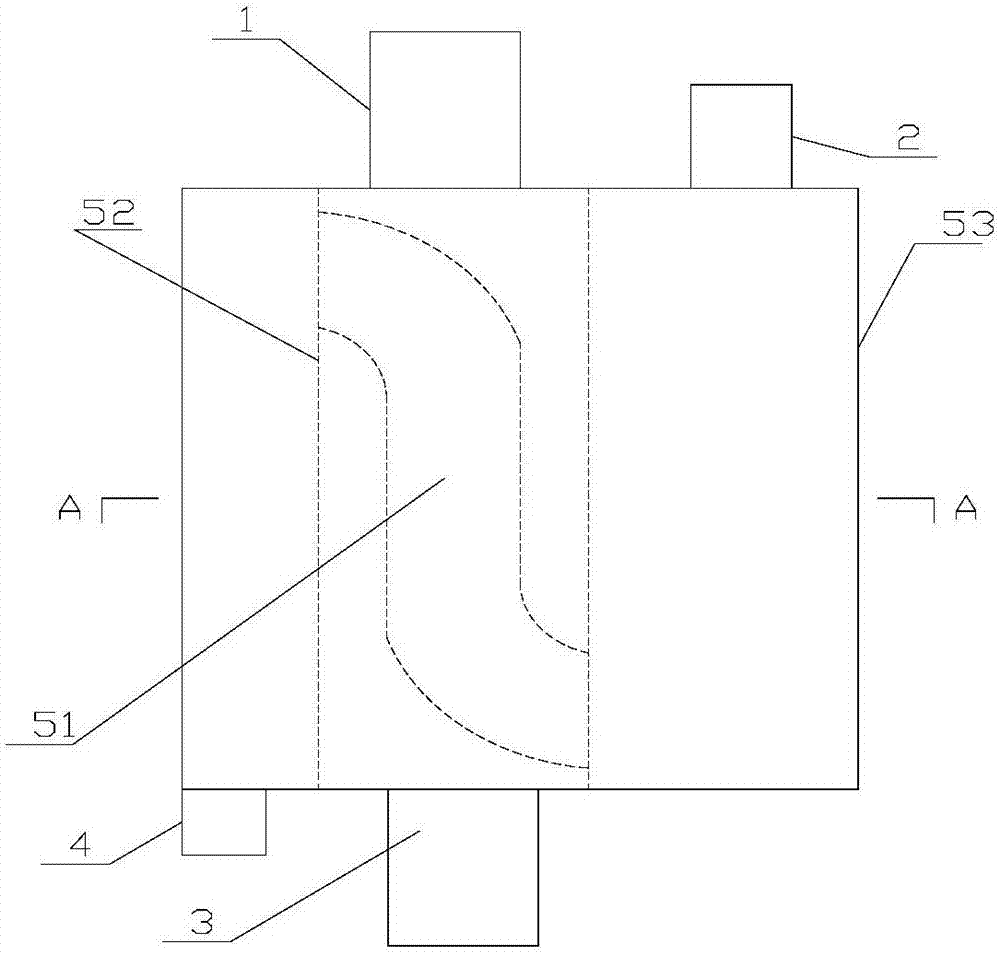

[0017] refer to figure 1 , figure 2 , image 3 with Figure 4 , a multi-flow three-pipe heat exchanger for a direct heating type heat pump water heater according to the present invention, comprising a hot water outlet 1, a refrigerant gas inlet 2, a cold water inlet 3, a refrigerant liquid outlet 4 and a multi-flow casing heat exchange tube 5, The multi-process sleeve heat exchange tube 5 includes a first sleeve 51, a second sleeve 52, a third sleeve 53, a first partition 54 and a second partition 55, and the two sides of the third sleeve 53 are The end is closed, and the third sleeve 53 is provided with a second sleeve 52 whose two ends are respectively sealed and fixedly connected with the upper and lower ends of the third sleeve 53. The connection between the second sleeve 52 and the third sleeve 53 The space is also fixedly connected by the first partition 54 and the second partition 55 which are symmetrically arranged, and the inside of the third sleeve 53 is cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com