Automatic net weaving machine

A net weaving machine, automatic technology, applied in the direction of online netting, other home appliances, home appliances, etc., can solve the problems of easy product length exceeding the error range, inconsistent product length, waste of production costs, etc., to achieve convenient product transportation and product consistency High, improve the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

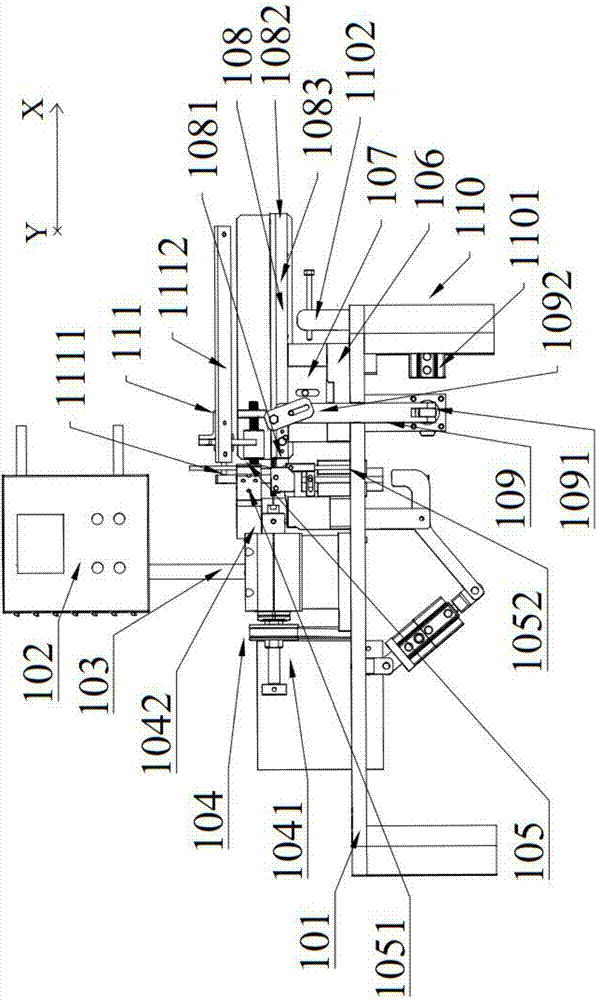

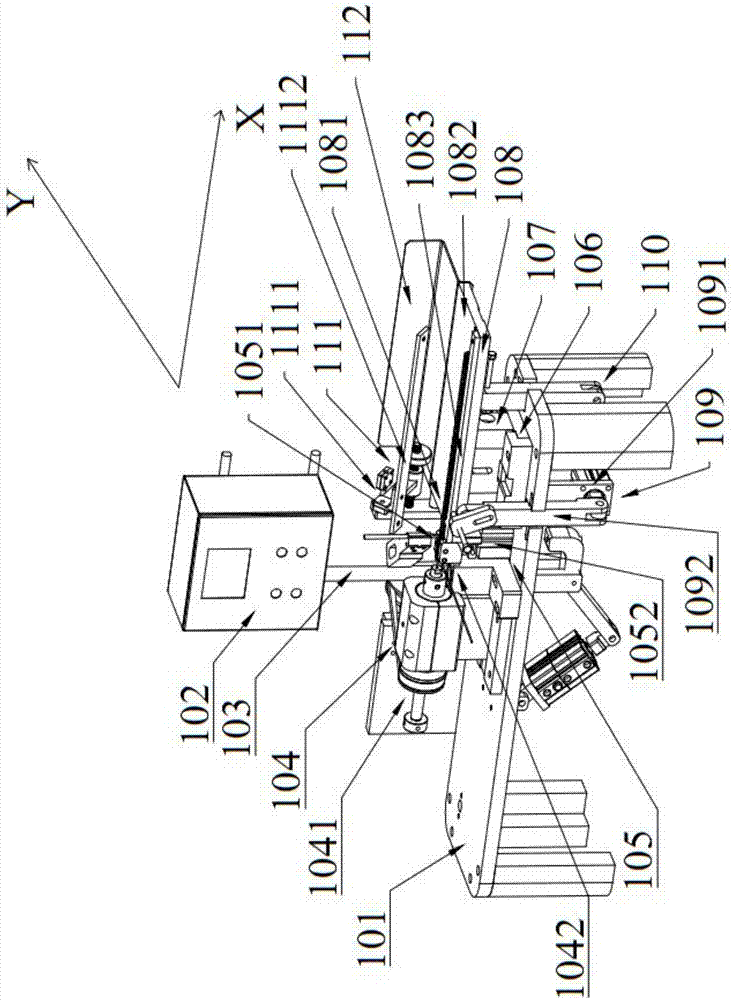

[0044] For clarity in the following description, the figure 1 The direction from the bottom to the top of the automatic weaving machine is defined as up, and the up and down direction is set as the X-axis direction, where the direction from bottom to top is the positive direction of the X-axis, and the direction perpendicular to the paper surface is set as the Y-axis direction , where the direction from the paper surface to the back of the paper is the positive direction of the Y axis, the positive direction of the X axis is the rear, and the negative direction of the X axis is the front; in addition, the side view of a single mesh belt semi-finished product is a circle with a diameter of d, and the step distance D Defined as a distance greater than 0 and less than d.

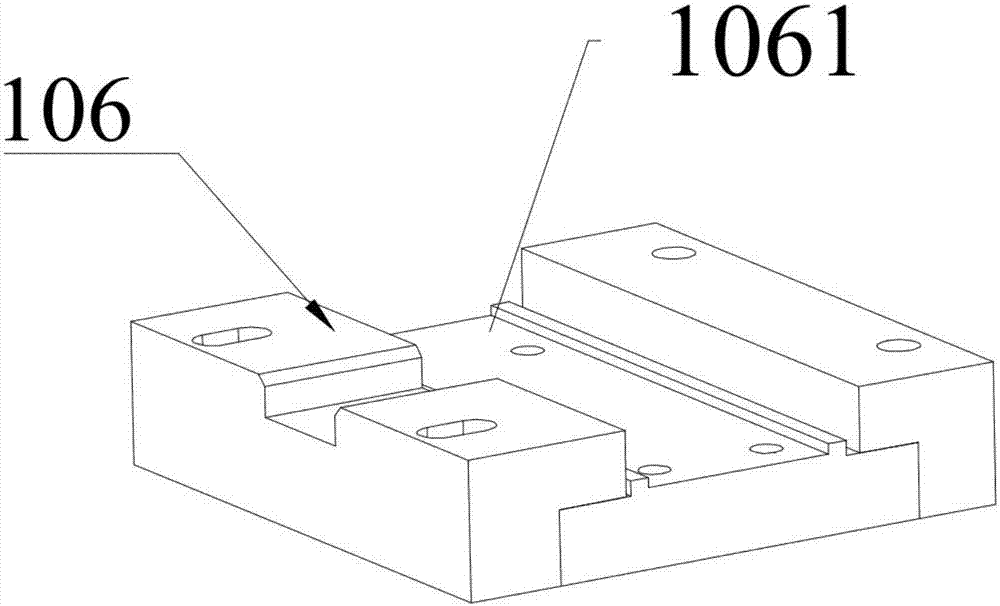

[0045] This embodiment provides an automatic weaving machine, please refer to Figures 1 to 3 As shown, are respectively the front view, the structural schematic diagram and the structural schematic diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com