A design method of internal flow channel of cooling plate based on streamline

A design method and cooling plate technology, applied in calculation, instrumentation, geometric CAD, etc., can solve problems such as dependence, achieve the effects of reducing design experience requirements, improving flexibility, and shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] see Figure 5 , The method for designing the internal flow channel of the cooling plate based on streamlines in the present invention includes a modeling step S11, a calculating step S12, a selecting step S21 and a generating step S22.

[0028] Modeling step S11, constructing a two-dimensional structural model with the inlet of the flow channel, the distribution area of the flow channel and the outlet of the flow channel, and determining the boundary conditions at the inlet of the flow channel and the outlet of the flow channel.

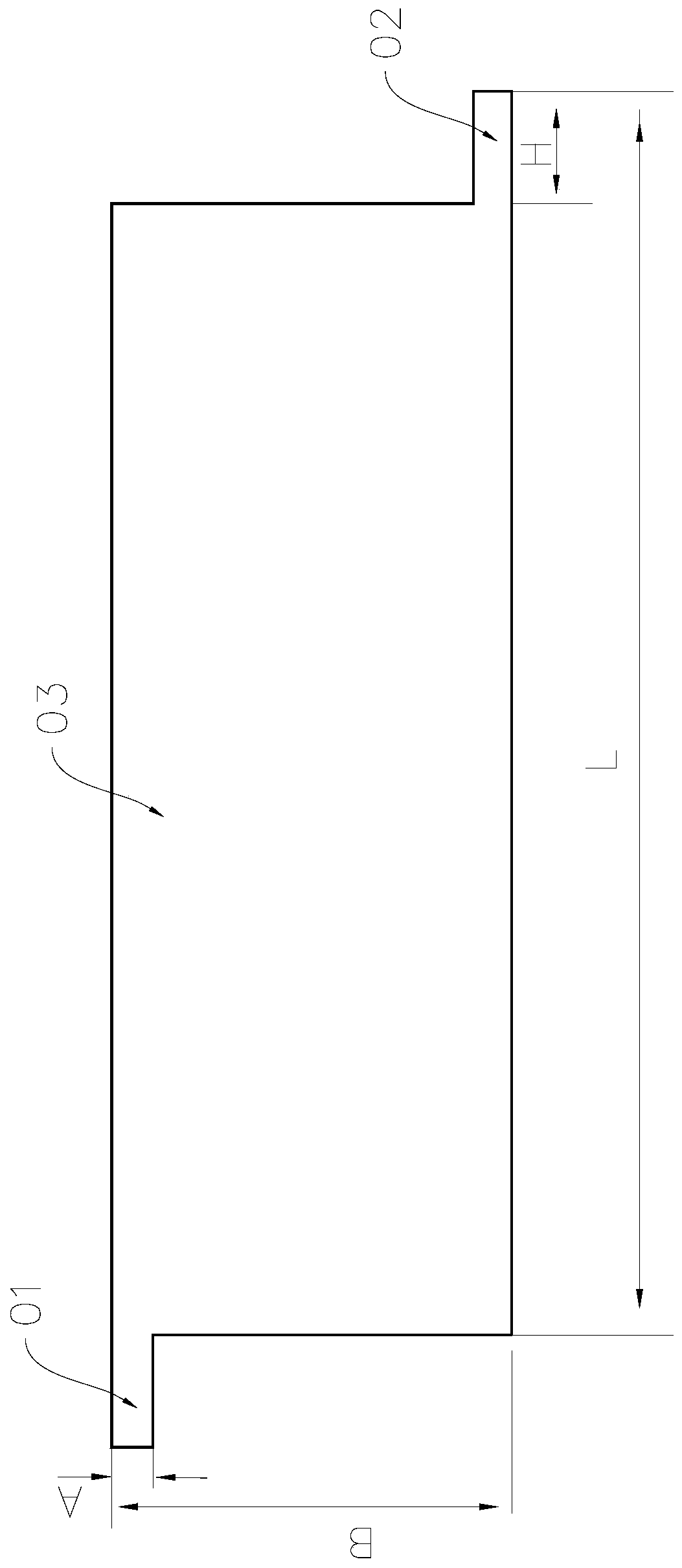

[0029] (1) if figure 1 As shown, the AUTOCAD software is used to construct a two-dimensional structural model with the runner inlet 01, the runner distribution area 02 and the runner outlet 03, that is, the thickness dimension of the cooling plate is not considered, and the specific dimensions are, L=330 mm, H= 30mm, B=100mm, A=10mm, the size of runner inlet 01 and runner outlet 03 are the same.

[0030] (2) The CFD pre-processing software...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com