Semiautomatic fruit harvesting machine applicable to paddy field work

A fruit harvesting, semi-automatic technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems of hot and high temperature in the harvesting season, harsh working conditions, low work efficiency, etc. Good stability and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

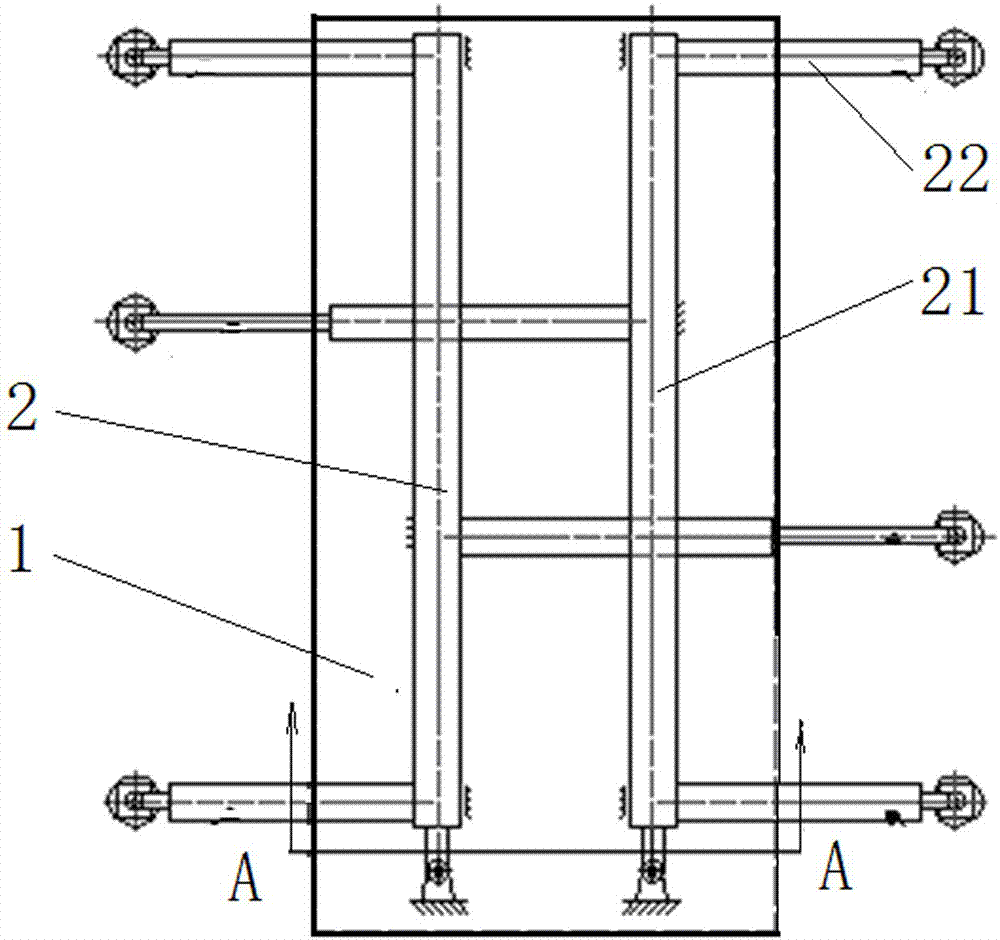

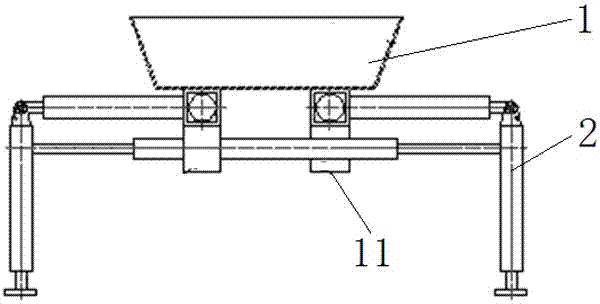

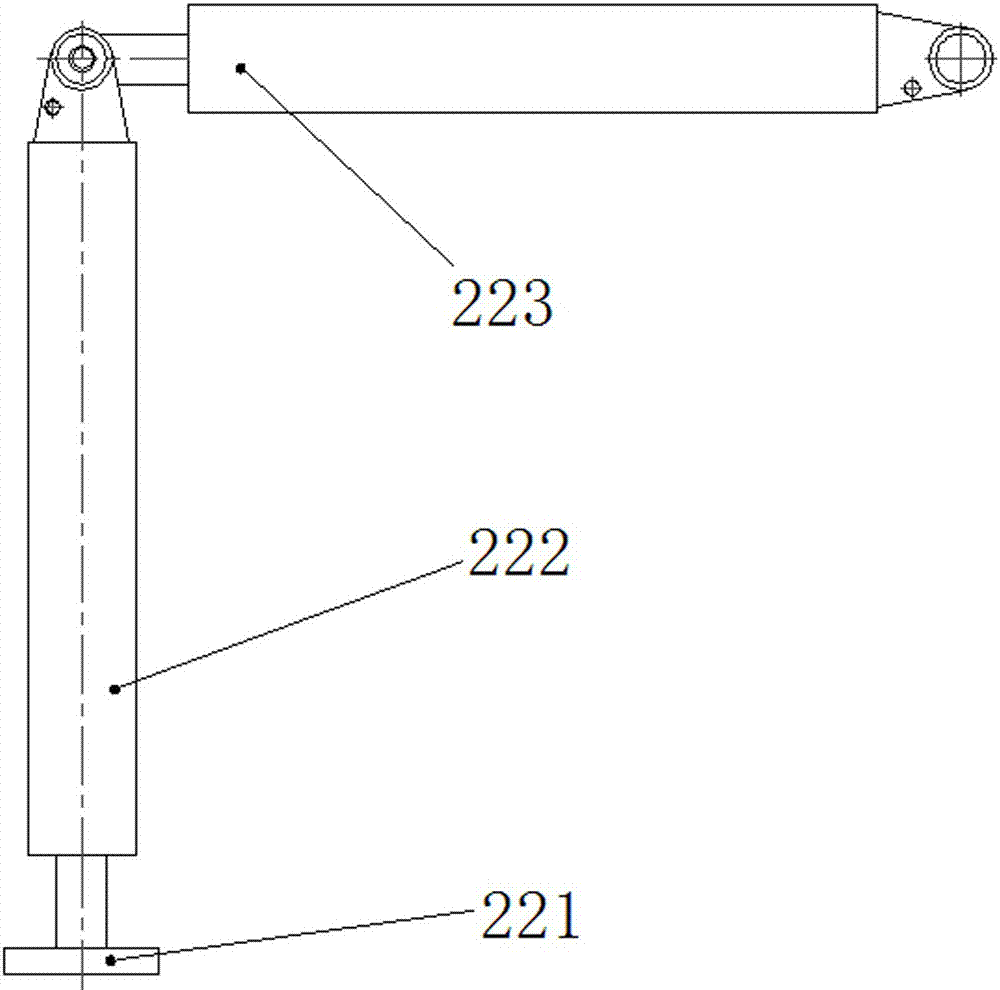

[0020] Such as figure 1 , 2 As shown, the present invention includes a mobile bracket 2 and a storage chamber 1; the mobile bracket 2 includes two parallel beams 21, one end of the beam 21 is connected to the base section 11 at the bottom of the storage chamber 1, and the beam 21 is driven by a cylinder. Made, able to expand and contract. Each beam 21 is provided with three outriggers 22 (not limited to three outriggers 22 , there may be more than three). Such as image 3 As shown, the supporting leg 22 includes a support plate 221, a shank 222 and a leg 223, the support plate 221 is installed on the bottom of the shank 222, the shank 222 is connected with one end of the leg 223, and the other end of the leg 223 is fixedly installed on the beam 21 Above, the shank 222 is perpendicular to the leg 223, and the shank 222 and the leg 223 are made of a cylinder and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com