Electrical plugging assembly

A technology of components and sockets, applied in electrical components, circuits, coupling devices, etc., can solve problems such as death, power failure, safety hazards, etc., and achieve the effect of convenient use, simple device structure, and reduction of electric shock accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

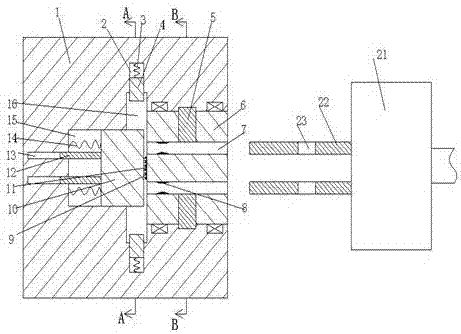

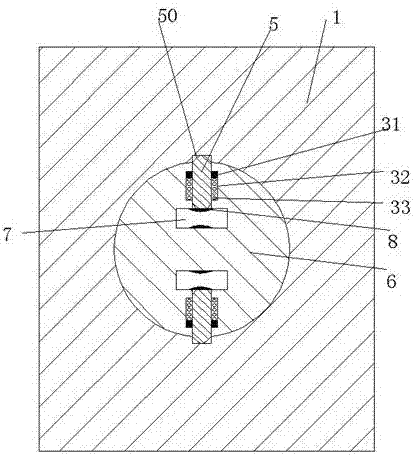

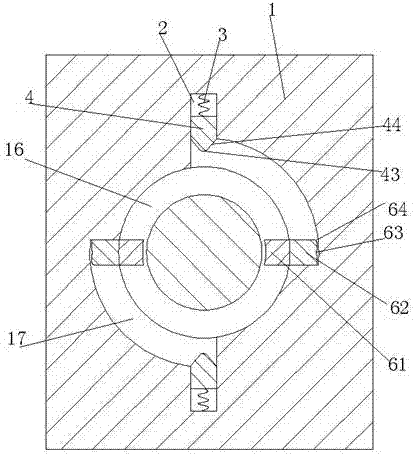

[0026] Combine below Figure 1-7 The present invention will be described in detail.

[0027] refer to Figure 1-7 , according to an embodiment of the present invention, an electric plug-in assembly includes a socket socket fixedly installed in the wall and a plug connector 21 connected to the electrical equipment, the socket socket 1 is provided with a right-opening Rotation hole, the rotation member 6 is rotatably installed in the rotation hole, and the insertion groove 7 connected to the left and right is symmetrically arranged in the rotation member 6 up and down, and the elastic conductive sheet 8 is fixedly installed in the insertion groove 7, A rubber sheet 11 is fixedly installed at the center of the left end surface of the rotating member 6, and the left end surface of the rubber sheet 11 is provided with a concave hole, and the socket 1 is provided with a circular groove 16 at the left end of the rotating hole. The center of the left end of the circular groove 16 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com