Locating device used for stepped shaft runout detection and locating method thereof

A technology for jump detection and positioning devices, which is applied in the direction of measuring devices, instruments, etc., can solve problems affecting detection efficiency and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] The positioning device for the jump detection of the stepped shaft of the present invention is applicable to various types of stepped shafts of different lengths. For the convenience of description, the present invention will take the left end as a small-diameter section and the right end as a large-diameter section for example. .

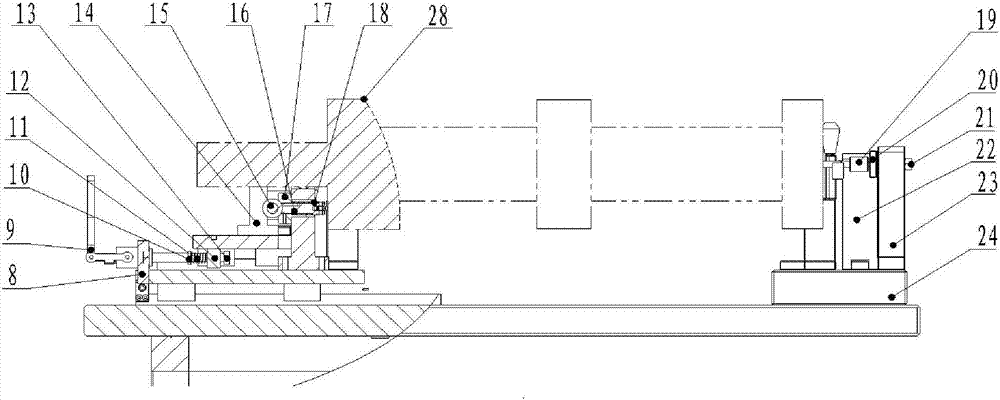

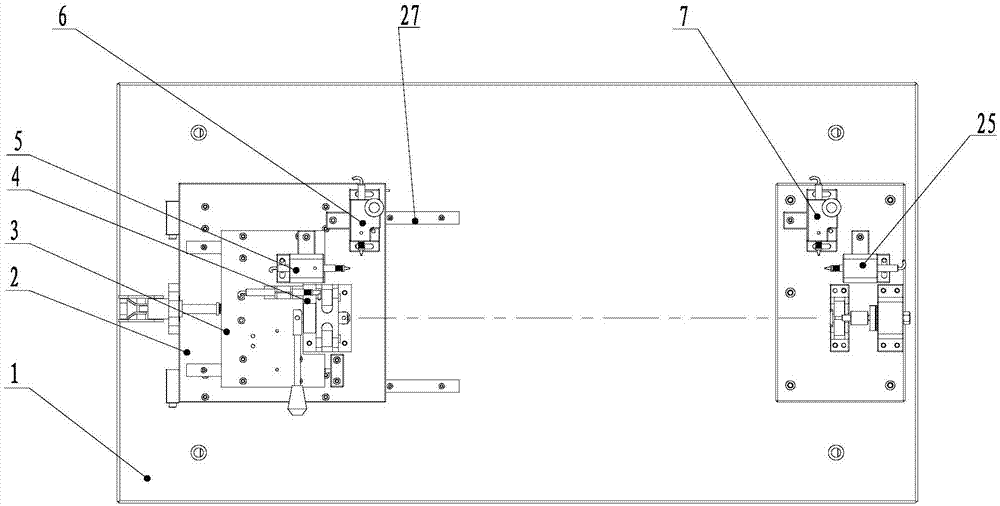

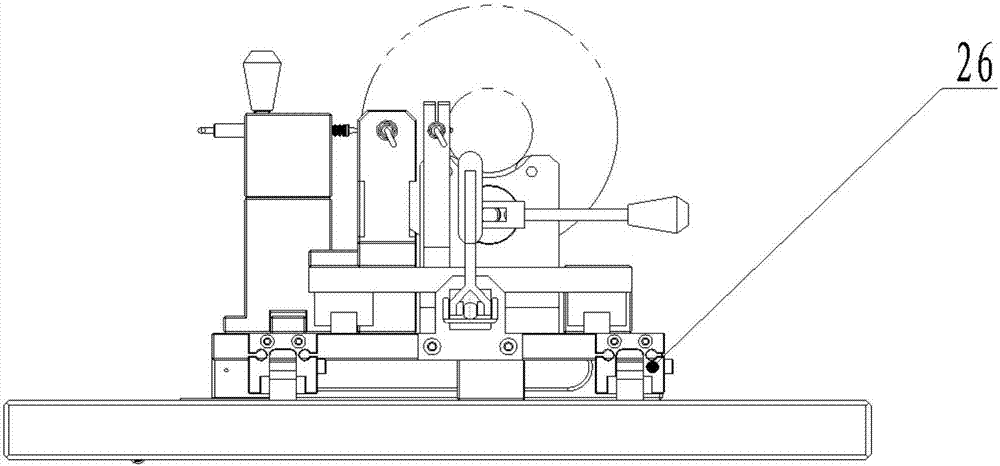

[0036] As shown in the figure, the present invention includes a horizontal abutment 1, a left end positioning mechanism and a right end positioning mechanism;

[0037] The right end positioning mechanism includes a right end support frame 22 fixedly connected with the horizontal base 1 to support the right end of the ladder shaft, and arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com