A trailer assembly system

An assembly system and vehicle frame technology, applied in the direction of motor vehicles, transportation and packaging, load suspension components, etc., can solve the problems of prolonging the assembly cycle, difficult positioning and installation, and prone to swing, so as to facilitate rapid assembly and accurately control assembly The effect of installation distance and accurate positioning hoisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing (be described ahead with the traction direction of tractor below).

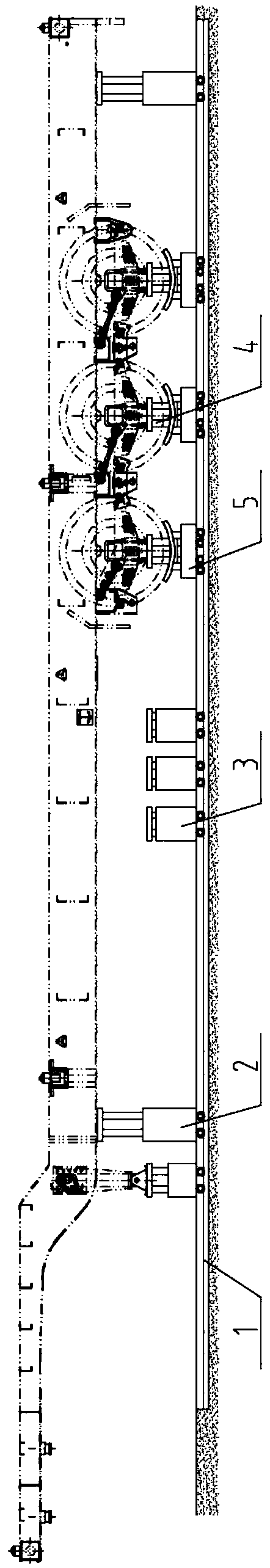

[0027] Such as figure 1 As shown, the trailer assembly system includes a horizontal linear guide rail component 1, a vehicle frame support component 2, a suspension support component 3, an axle support component 4, a wheel support component 5 and an electric control device.

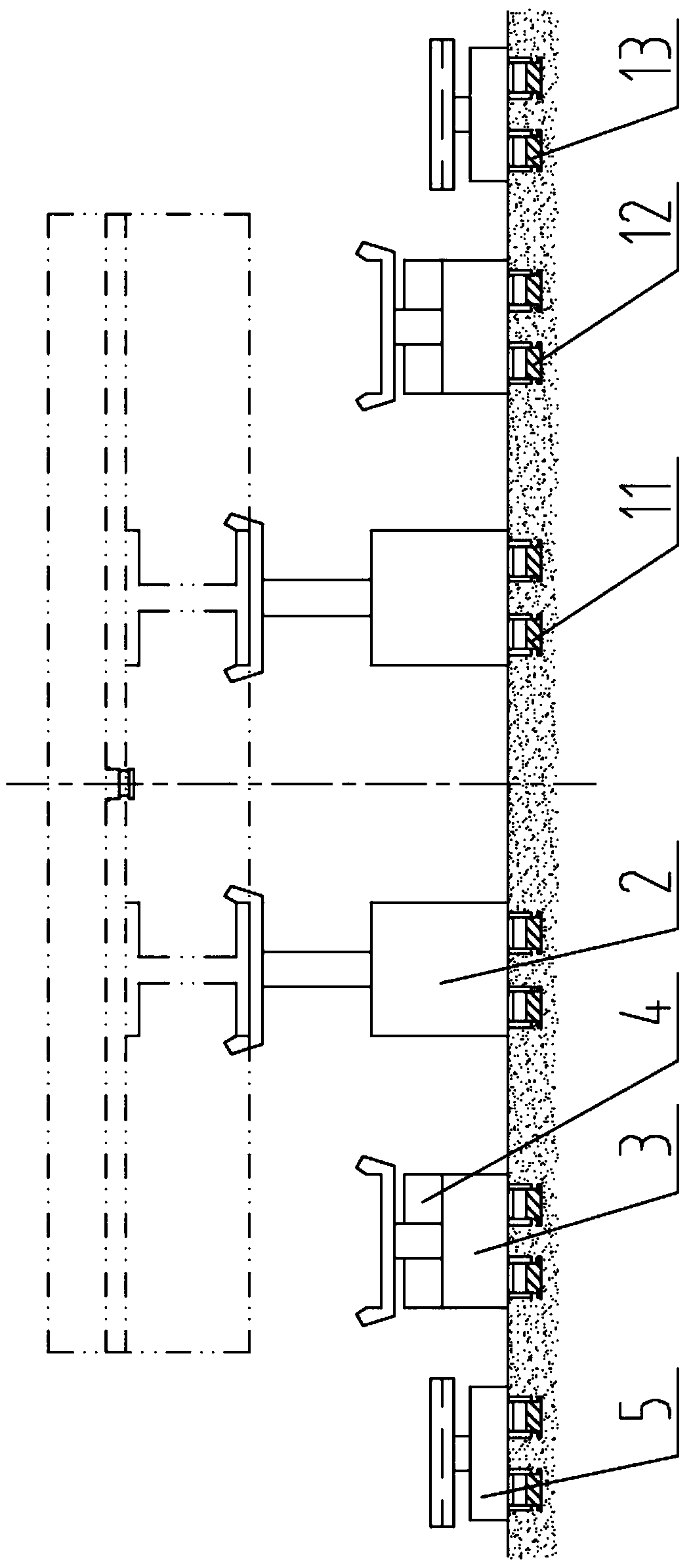

[0028] The horizontal linear guide rail component 1 is a left-right symmetrical parallel guide rail structure, such as figure 2 As shown, it includes at least left and right symmetrically arranged frame mounting guide rails 11, axle mounting guide rails 12 and wheel mounting guide rails 13. 13 is located outside the span of the axle installation guide rail 12.

[0029] The frame supporting part 2, the suspension supporting part 3, the axle supporting part 4 and the wheel supporting part 5 are arranged symmetrically from left to right,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com