Rotary contact type cloth singeing mechanism

A contact and cloth technology, applied in the field of textile production, can solve problems such as low production efficiency and poor singeing quality, and achieve the effects of reducing energy consumption, improving singeing effect, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

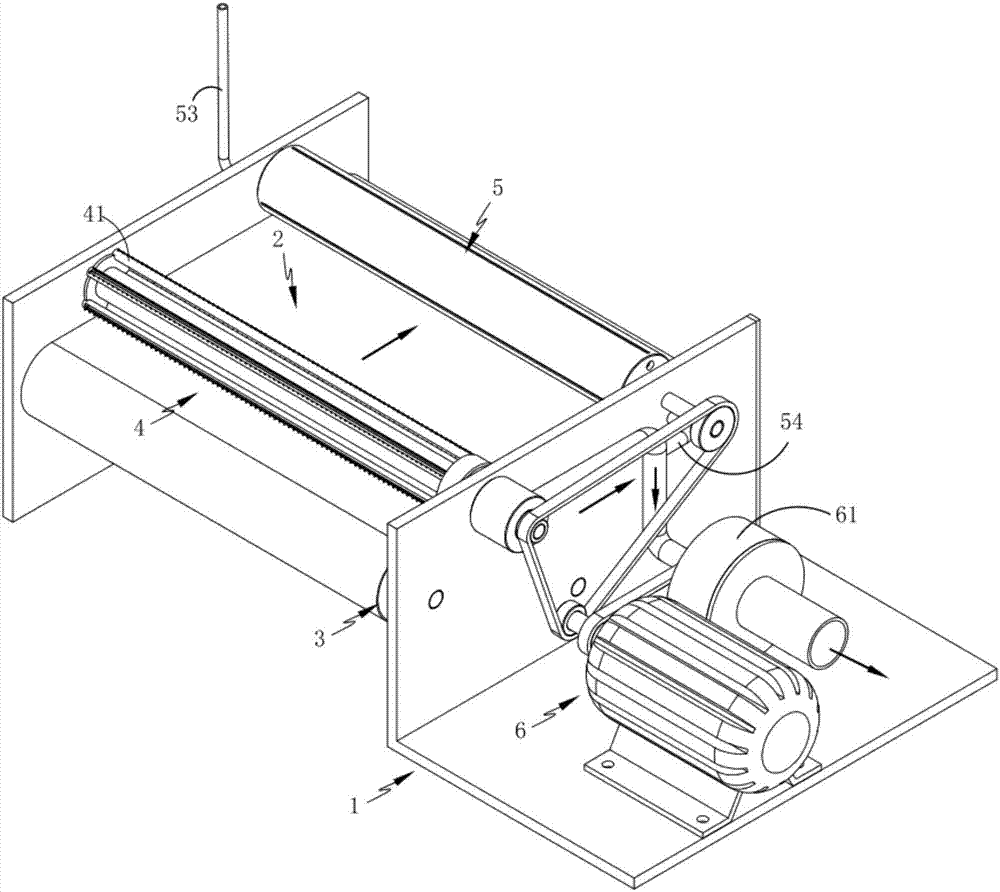

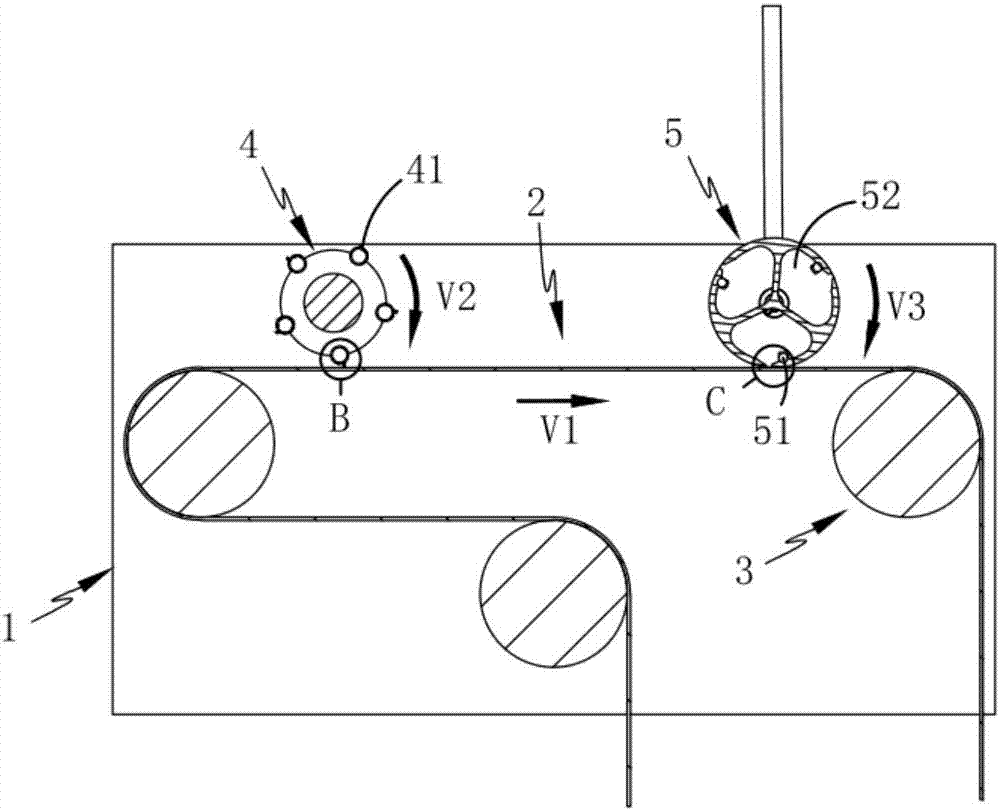

[0038] Such as figure 1 , 2 , 3, 4, 5, 6 and 7, a rotary contact type cloth singeing mechanism, including a support 1 and a plurality of cloth guide rollers 3 that are rotatably mounted on the support 1 and carry out cloth 2 transmission along a certain track, and also include:

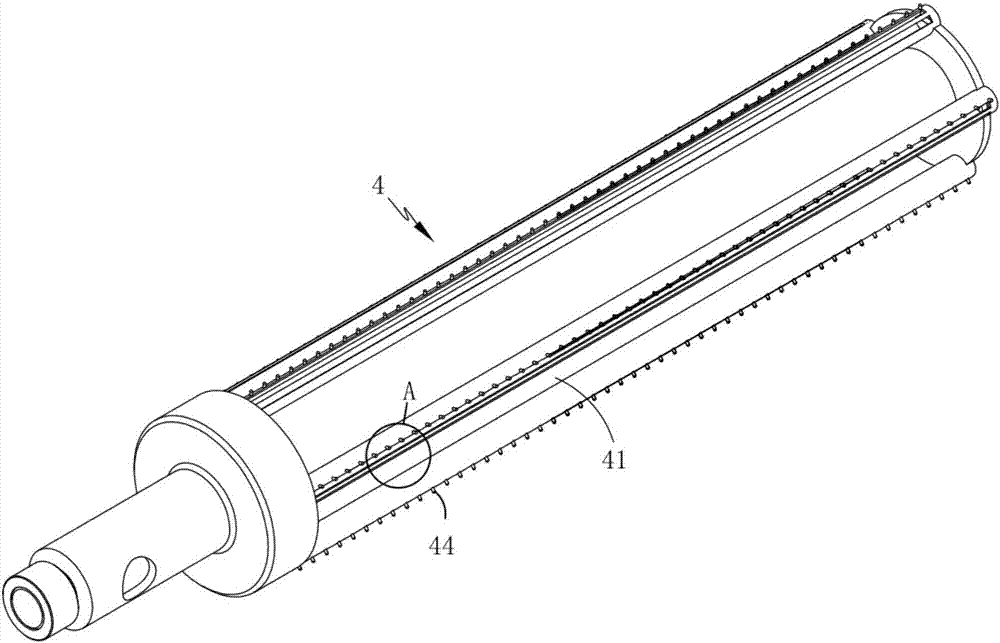

[0039] Finishing component 4, said finishing component 4 is rotatably installed on said bracket 1 and is located above said cloth 2, wherein, cloth 2 is in a tensioned state, and said finishing component 4 is arranged on it and inside during rotation The adsorption tube 41 that is set for negative pressure carries out the traction of the fiber on the surface of the cloth 2 through the adsorption channel 42 opened on it, and then performs secondary fiber adsorption through the shaped suction port 43 arranged at an angle with it; the adsorption channel 42 and the shaped suction port 43 communicate with the inside of the adsorption pipe 41 respectively, and the suction channel 42 and the shaped suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com