Metal bucket posture finishing equipment and metal bucket posture finishing method

A metal barrel, posture technology, used in transportation and packaging, stacking of objects, conveyor objects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The metal bucket posture sorting device includes a circumferential sorting mechanism, a first-level turning mechanism is arranged in front of the circumferential sorting mechanism, and a second-level turning mechanism is arranged in front of the first-level turning mechanism. Between the circumferential sorting mechanism and the first-level turning mechanism, there is a first parallel transmission mechanism responsible for parallel transfer of metal barrels, and between the first-level turning mechanism and second-level turning mechanism, there is a The second parallel transmission mechanism;

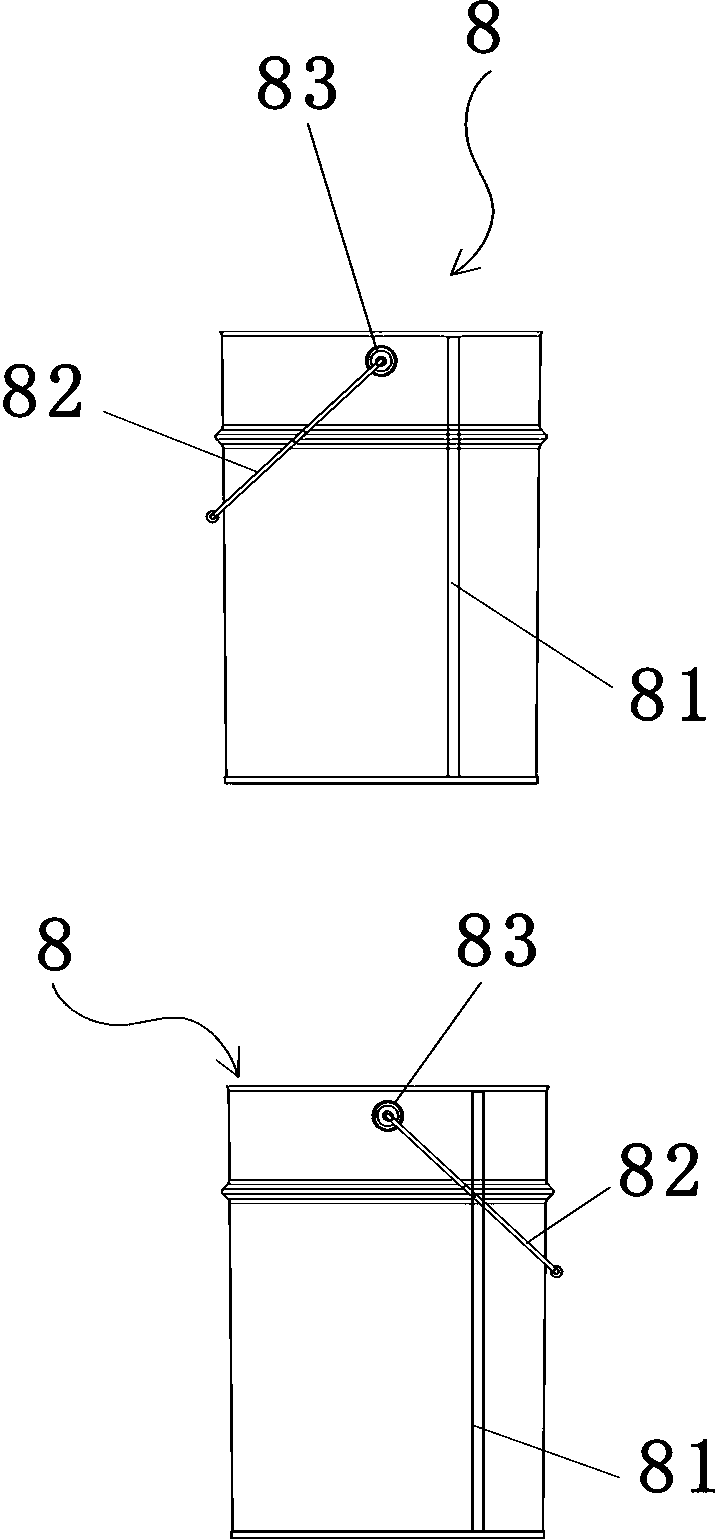

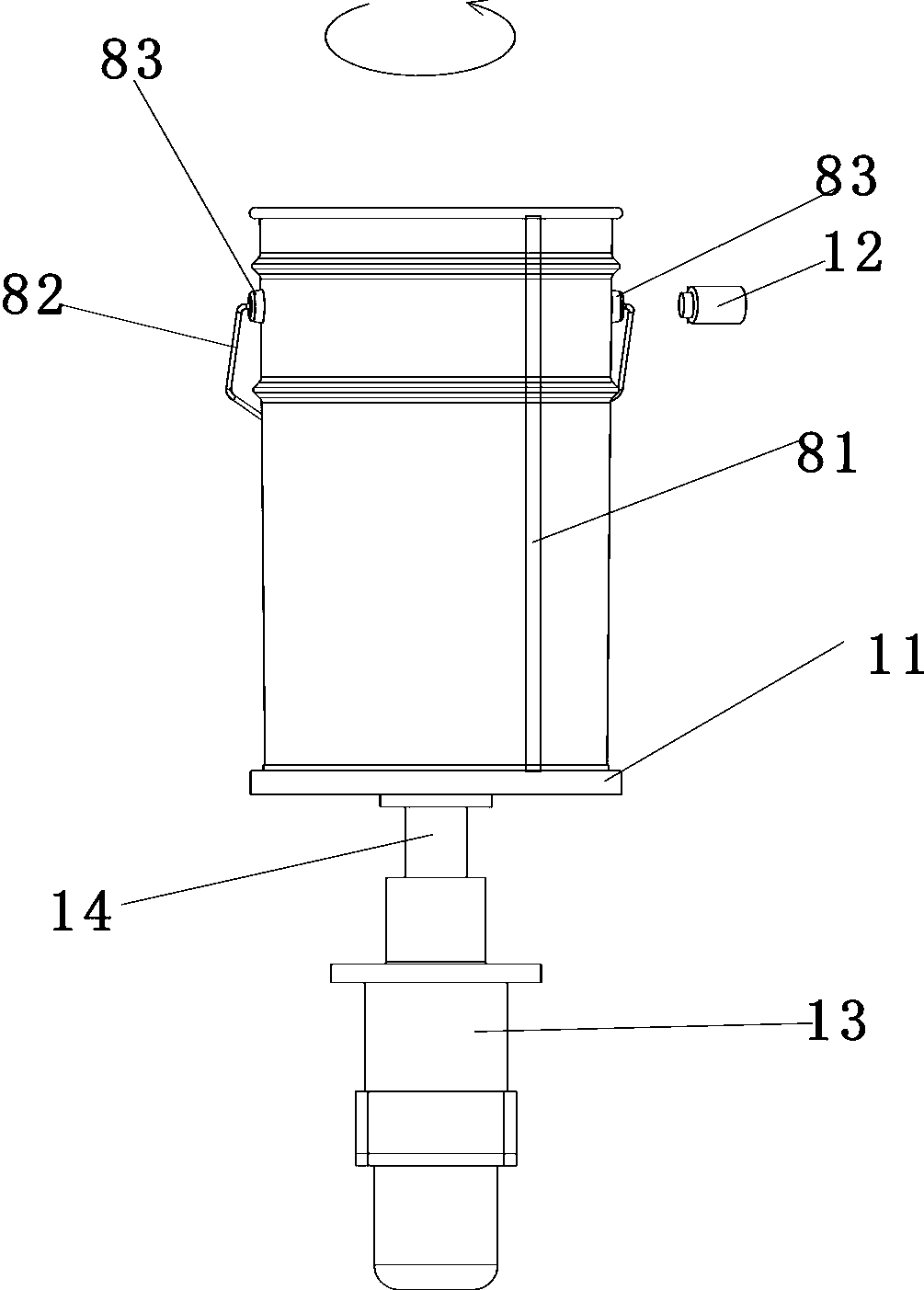

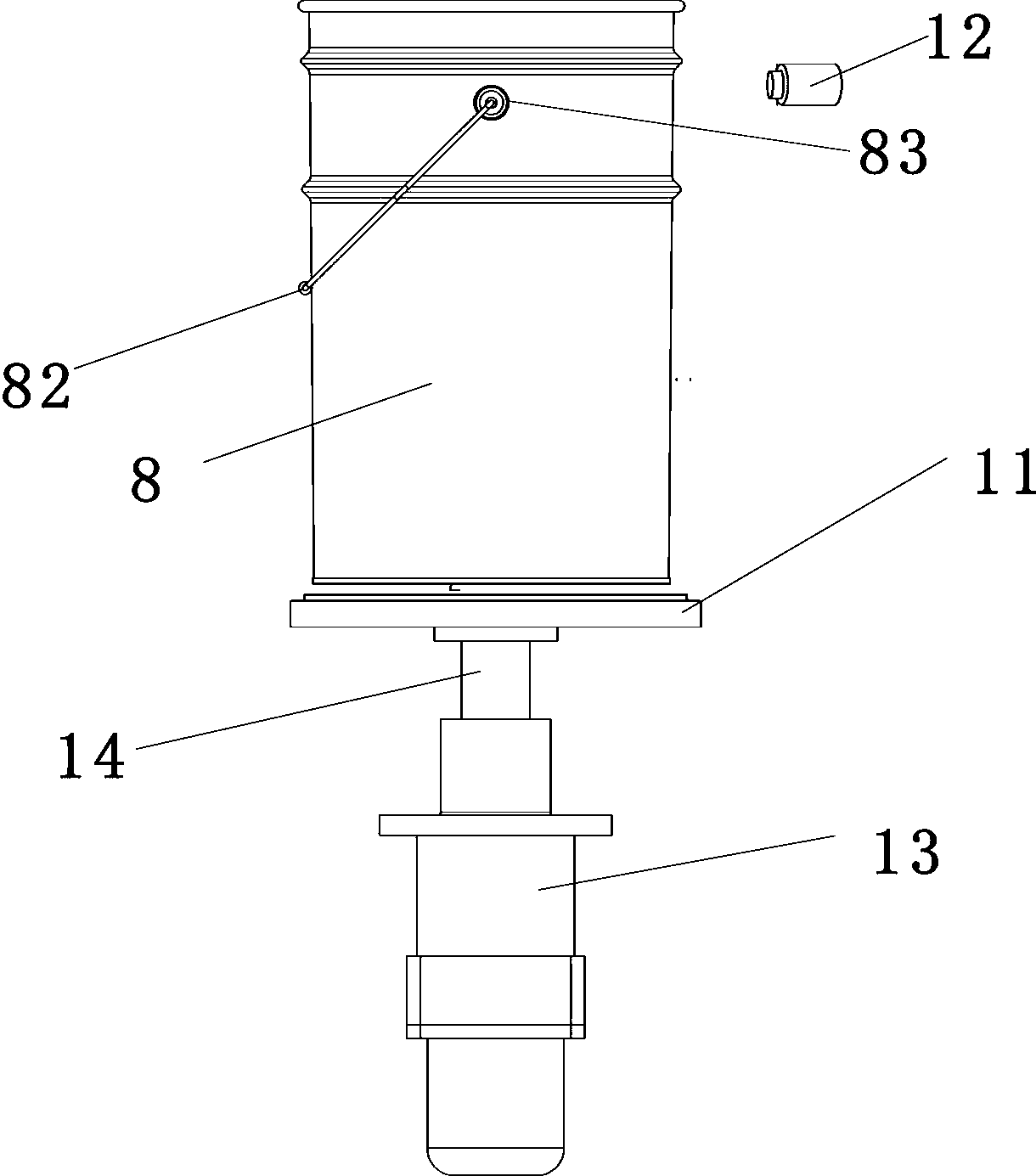

[0042] figure 2 , image 3 As shown, the circumferential finishing mechanism includes a rotating base 11 and a sensor 12 for identifying circumferential markers on the barrel wall (specifically, vertical welds). The sensor 12 is installed on the periphery of the space above the rotating base 11; the rotating base 11 is controlled by a servo motor 13 Driven, the shaft 14 of the...

Embodiment 2

[0046] A metal bucket posture sorting method, using the metal bucket posture sorting equipment of Embodiment 1, includes the following steps in sequence:

[0047] (1) Before starting the posture adjustment work of the metal barrel, adjust the installation position of the sensor 12 according to the relative orientation relationship between the vertical weld of the metal barrel wall and the lifting lug in the circumferential direction of the metal barrel wall, so that the sensor 12 is relatively The orientation of the rotating shaft 14 of the rotating base meets the following conditions: when the vertical weld seam of the barrel wall of the metal barrel placed on the rotating base rotates to align with the sensor 12, the direction of the line connecting the center points of the two handles of the metal barrel is horizontal ;

[0048] (2) Put the metal barrel 8 in an upright posture on the rotating base 11 of the circumferential finishing mechanism, and the servo motor 13 drives ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com