Visual-model testing apparatus and testing method for seepage-stress-coupled internal piping penetration

A model test device and model test technology, applied in measurement devices, hydraulic models, permeability/surface area analysis, etc., can solve problems such as inaccurate readings, cumbersome measurement process, and inability to obtain internal piping, and achieve easy operation and adjustment. , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

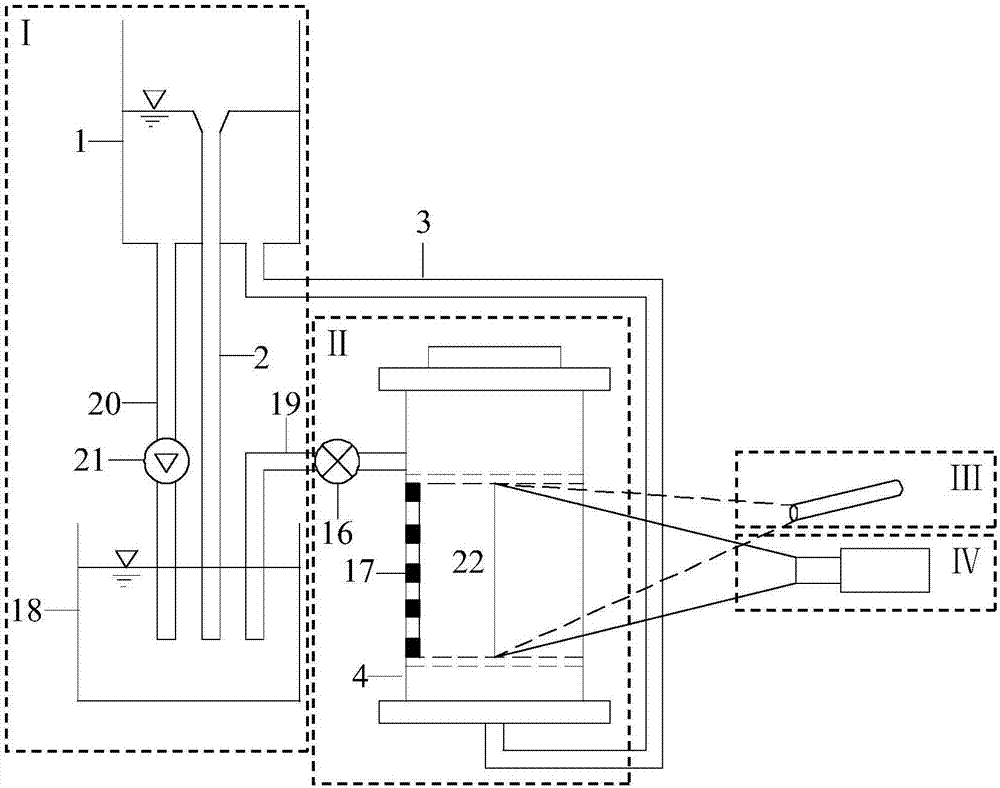

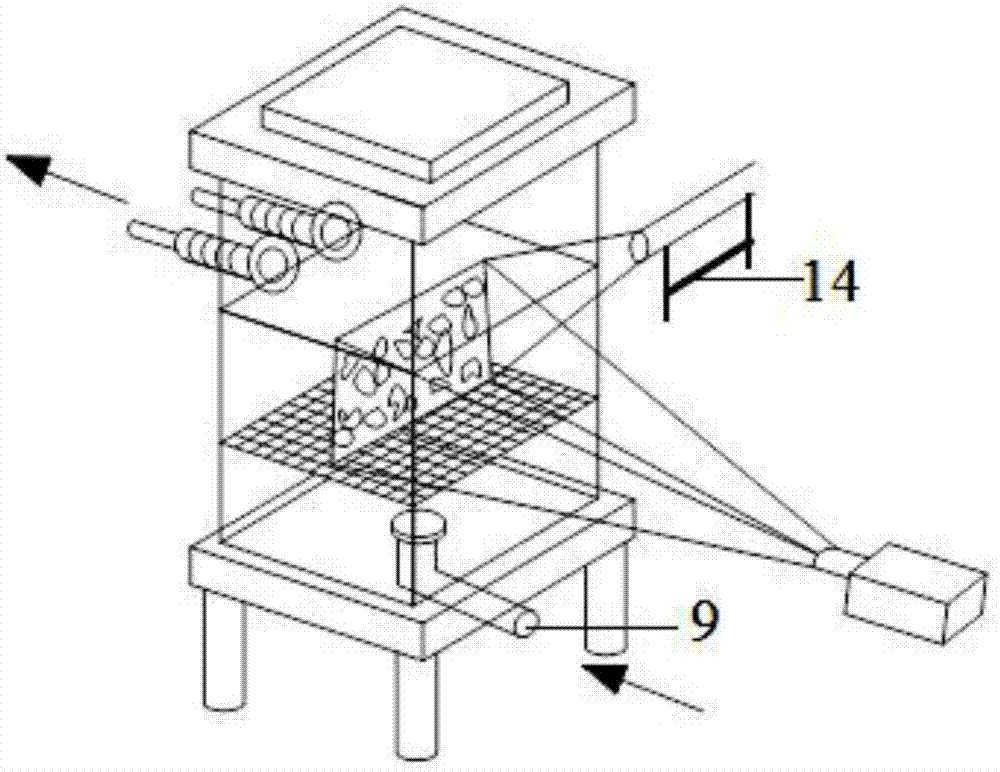

[0038] Such as Figure 1 to Figure 2As shown, a visual model test device for seepage stress coupling internal piping seepage, including variable water head control and liquid circulation system I, vertical loading infiltration system II, laser control system and IV image acquisition system III, variable water head control and liquid circulation system I It has the function of liquid circulation, uses the overflow pipe 2, the inlet pipe 3, the outlet pipe 19 and the suction pipe 20 to connect the three water bodies in the water tank 1, the circulating water tank 18 and the transparent model box 4, and maintain the water through the water pump 21 Circulation; vertical loading infiltration system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com